PRONCIPLE

Principle

Principle of surface treatment

Laser surface treatment uses laser beam thermal energy fast to heat workpiece in partially to drive it hot or cold sharply, it can be deal with in astmosphere or vacuum enviroment and sovoled various surface treatment process via change laser parameters.

ADVANTAGE

Technical Advantages

-

Steel Shell Marking

-

Aluminum shell black code marking

-

Steel shell/aluminum shell explosion-proof valve etching

-

Precision removal of surface coatings

-

PCB Marking

-

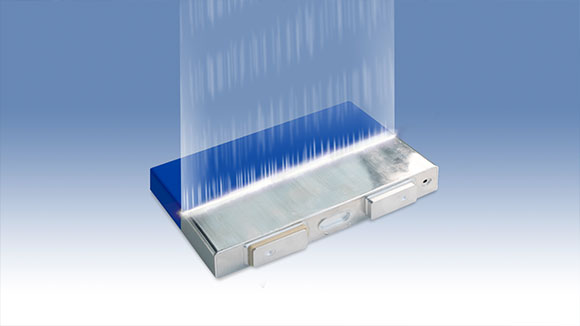

Waterproof Membrane Removal

-

Electrode surface ablation

-

Micro-texture of the aluminum shell of batteries

-

Ablation of blue adhesive and protective film

-

Trimming

-

Multiple chip removal techniques

-

Topcon Laser doping thechnology

-

Steel Shell Marking

Steel Shell Marking- Can mark 3*3mm two-dimensional code or 1mm high 15-digit clear code steel shell within 1s, size of two-dimensional code mark can be 1*1mm.

-

Aluminum shell black code marking

Aluminum shell black code marking- With nanosecond lasers to mark black codes on a white background, which solves the problems of invalidation and low grade of two-dimensional codes.

-

Steel shell/aluminum shell explosion-proof valve etching

Steel shell/aluminum shell explosion-proof valve etching- The depth of the processing groove is X±10μm, and the blasting value is Y±0.2Mpa, which replaces the traditional stamping and improves the safety performance of the battery.

-

Precision removal of surface coatings

Precision removal of surface coatings- Finely remove surface coating less than 1um with no damage to the product, and developed deplating technology.

-

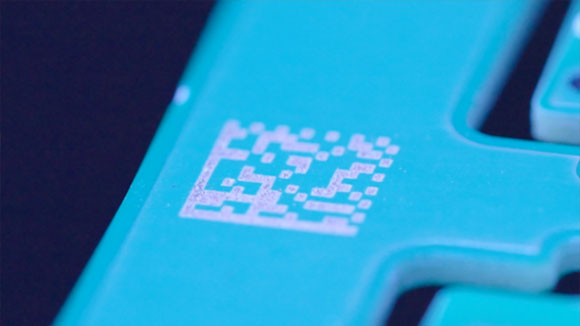

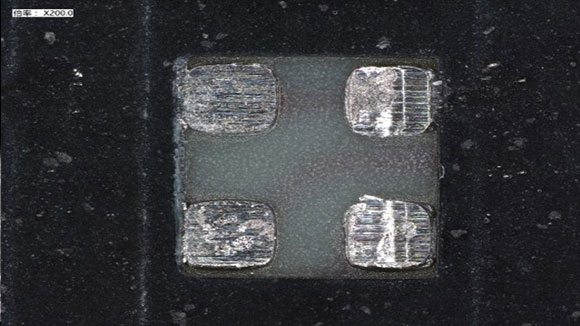

PCB Marking

PCB Marking- Green light laser marking technology, marking and visual positioning are synchronized, 1x1mm (DM) covers 20 bits of content, resolution 3mil, replacing traditional inkjet coding and paper label technology.

-

Waterproof Membrane Removal

Waterproof Membrane Removal- Using laser to remove parylene, the removal rate exceeds 95%, the laser removal quality is not lower than Sa2.5 level, the removal thickness is better than 3μm, and the removal efficiency is greater than 2㎡/h.

-

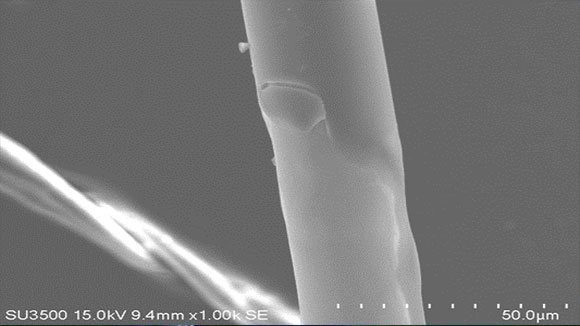

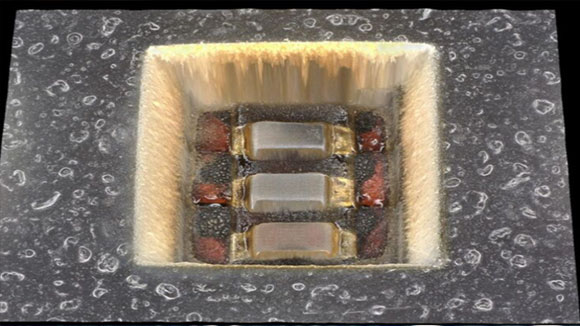

Electrode surface ablation

Electrode surface ablation- Partial ablation of coated electrode can increase coated area and improve battery capacity. Such ablating method can efficiently avoid the lithium plating during the formation process, and enhance the safety and performance of the battery.

-

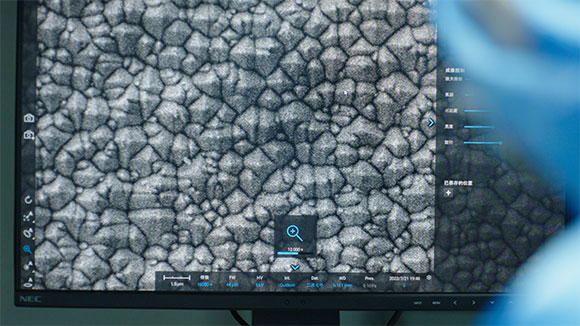

Micro-texture of the aluminum shell of batteries

Micro-texture of the aluminum shell of batteries- The innovative ablation solution replaces the traditional method and satisfies the roughening of any special-shaped surface.

-

Ablation of blue adhesive and protective film

Ablation of blue adhesive and protective film- As an industry-leading technology, it solves the problem of excessive ablation of the film edge and makes up for our company's gap in laser ablation technology.

-

Trimming

Trimming- A high-precision intelligent machining system that realizes Mini/Micro LED repair and leveling process.

-

Multiple chip removal techniques

Multiple chip removal techniques- Provide a precise, flexible and intelligent solution for Mini LED chipless process.

-

Topcon Laser doping thechnology

Topcon Laser doping thechnology- The revolution and international advanced technology in PV that improve solar cell performance significantly, decrease energy comsuption and pollution by break conventional process.

APPLICATION

Application

-

3C

3C -

Photovoltaic

Photovoltaic -

New display

New display -

EV power

EV power

PRODUCTS

Products

Products relative to laser devices

-

EV Battery

-

Electronics

-

Photovoltaic

-

Life Sciences

-

Transports

-

Sheet-metal Working

-

-

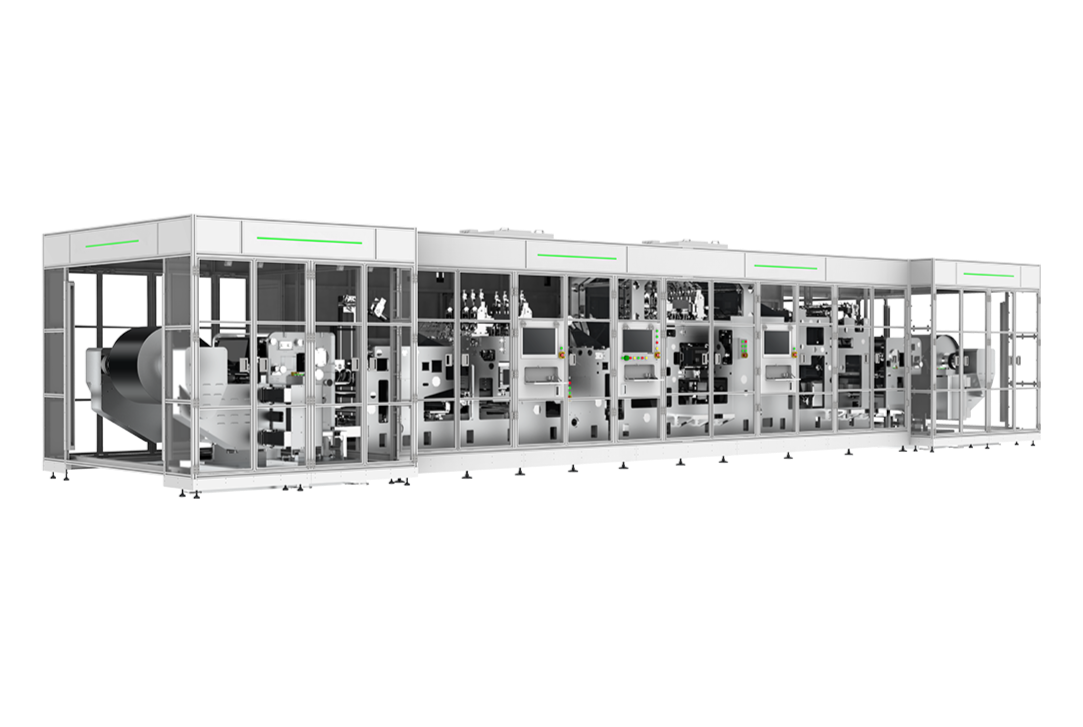

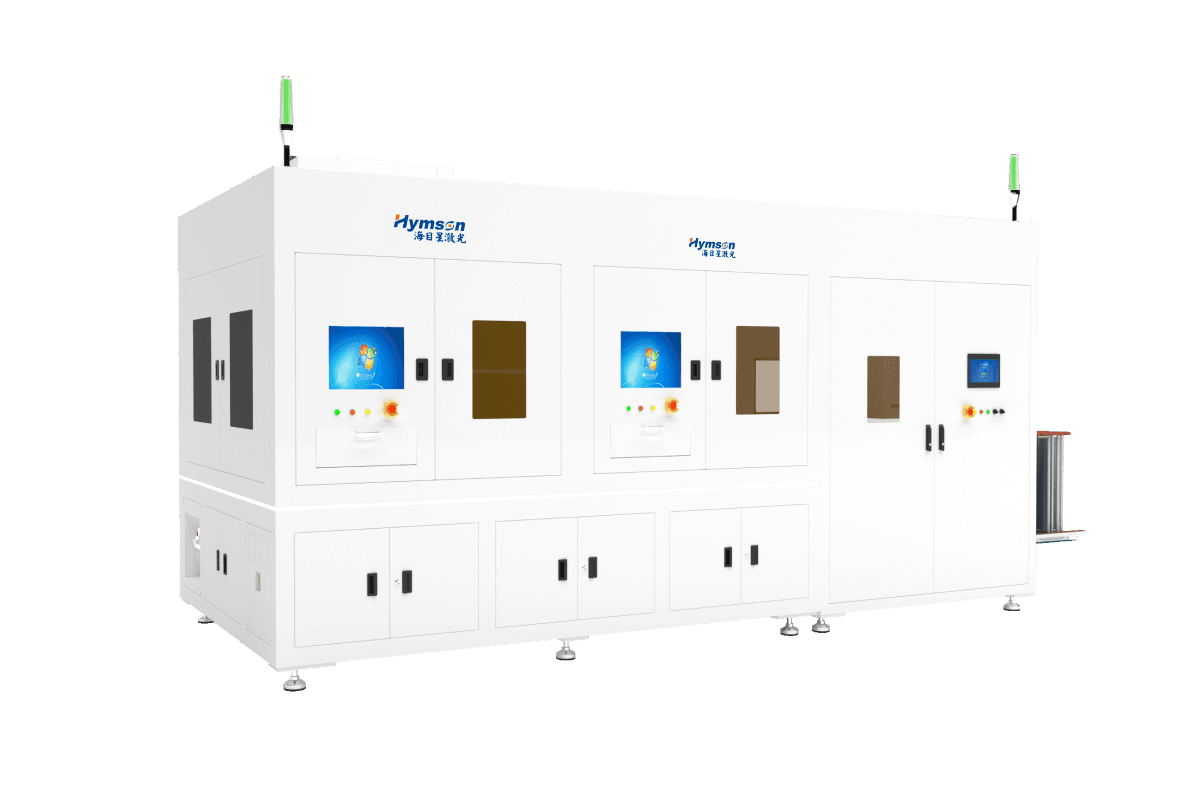

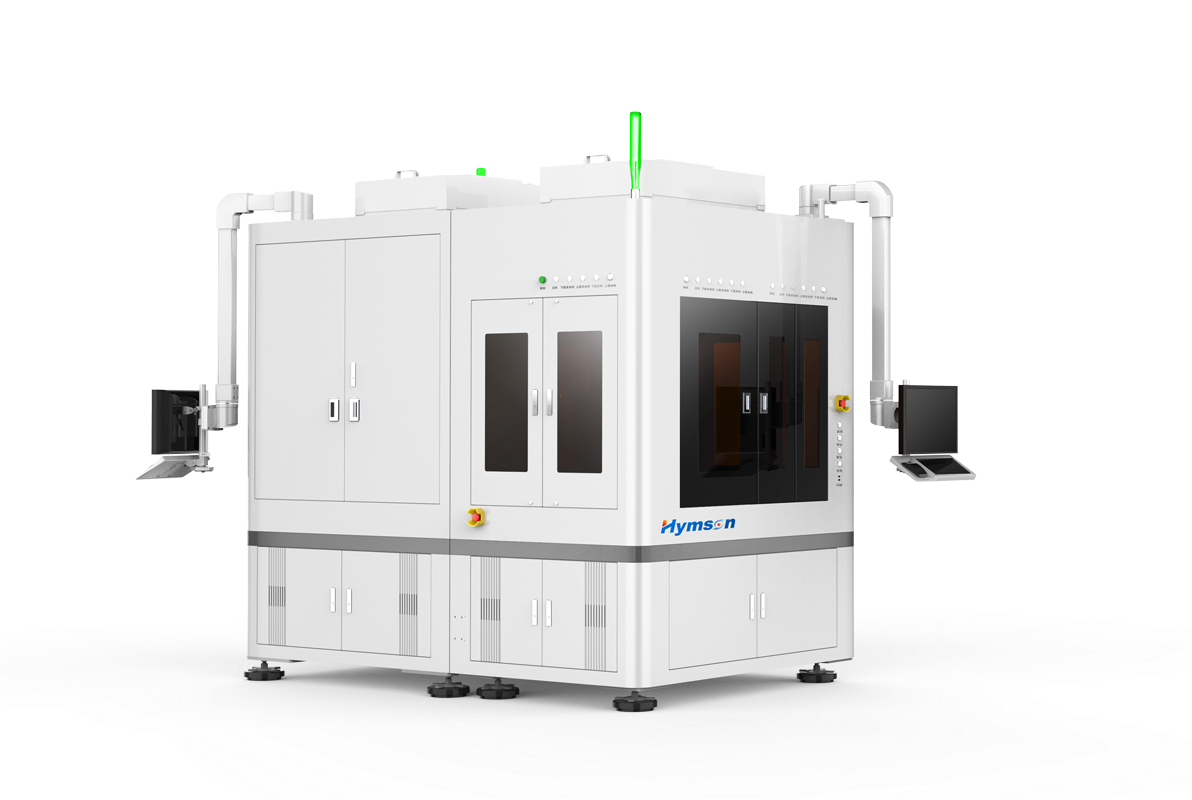

View ProductsMulti-Lane Laser Ablation Machine

View ProductsMulti-Lane Laser Ablation Machine-

Large plate supporting structure on both sides.

-

Highly accurate feeding unit.

-

High-precision OCTO laser position adjustment system.

-

High tension control accuracy enabled by multi-section electrode buffering system and tension control system; Compatible with A-A, A-B, B-B side ablation.

-

-

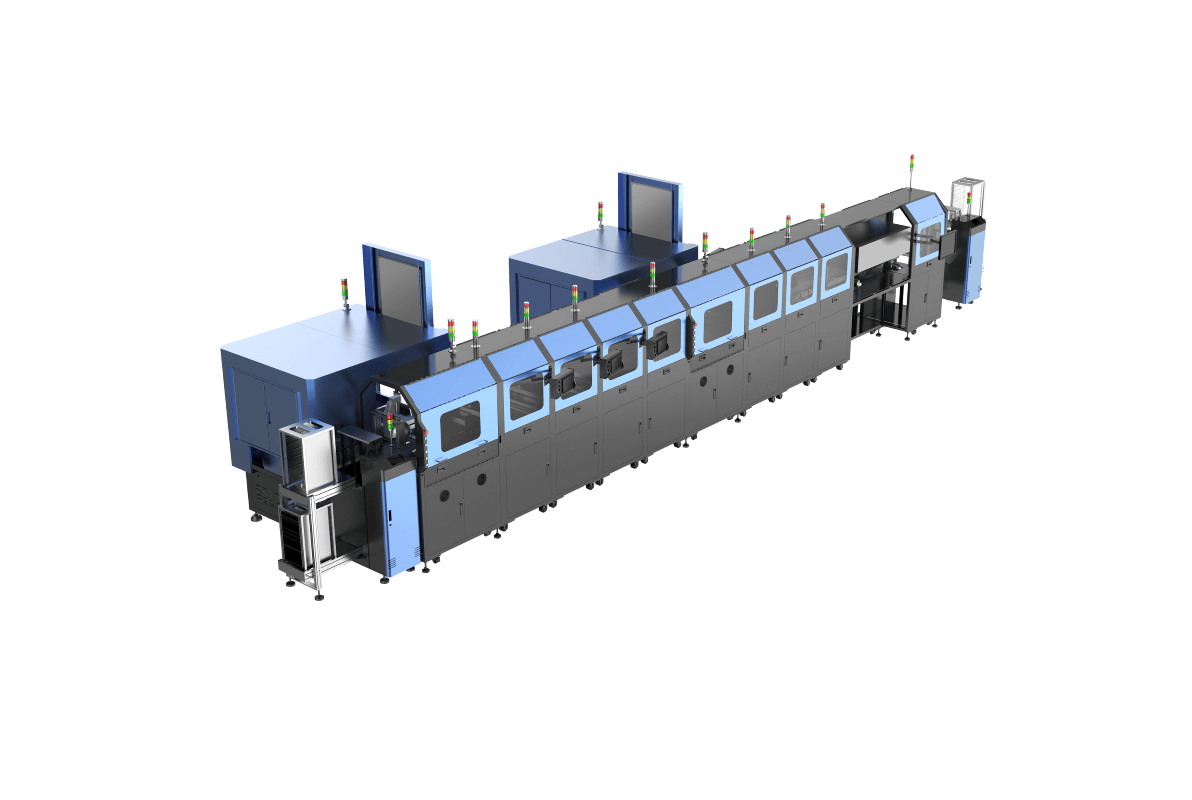

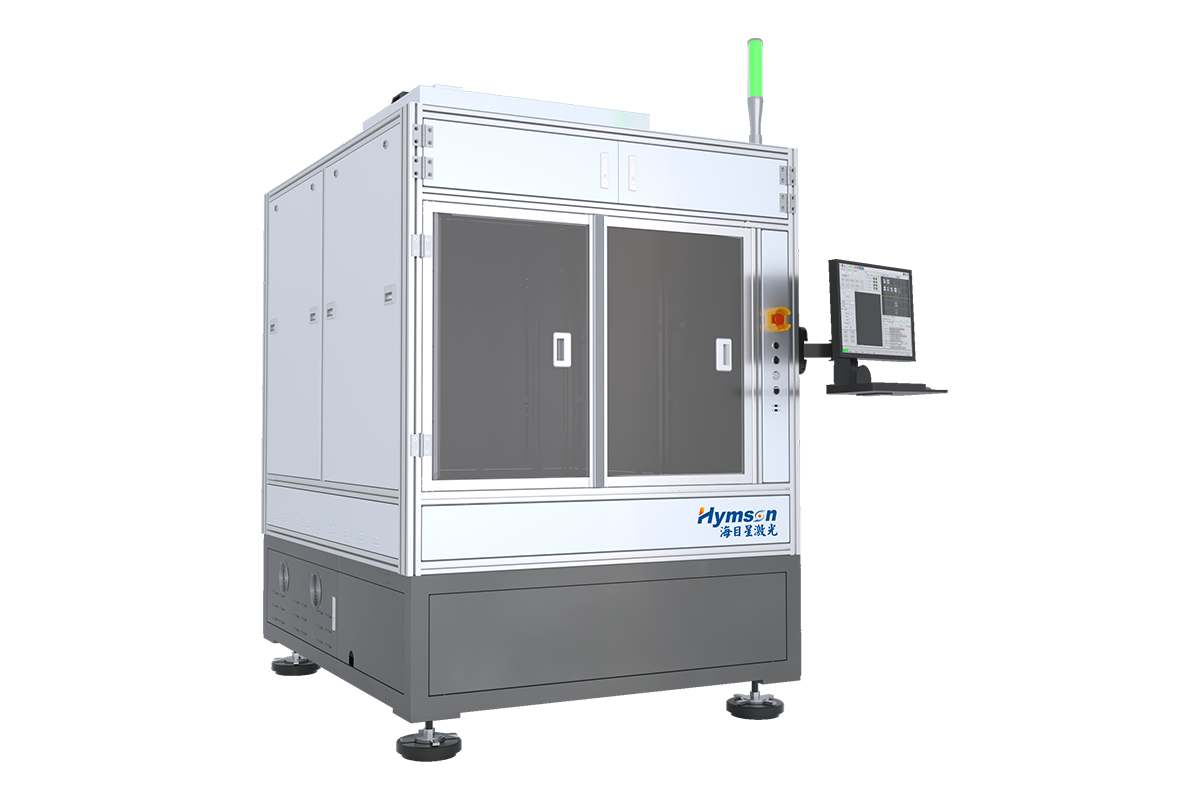

View ProductsSingle-Lane Laser Ablation Machine

View ProductsSingle-Lane Laser Ablation Machine-

Cantilever supporting structure with large plate on single side.

-

Highly accurate feeding unit.

-

Time-sharing laser ablation system.

-

High tension control accuracy enabled by multi-section electrode buffering system and tension control system.

-

-

-

-

View ProductsLaser Glue Removal Line

View ProductsLaser Glue Removal Line-

The machine adopts the simplex station single rack mode, and the number of freely assembled machine matches the UPH.

-

The machine adopts square welded frame+air spring roller type open and close door structure, with atmospheric appearance

-

The left and right products are switched with tool-free quick-change structure, and the production switching time of the left and right boards is less than 30min.

-

Precision laser cutting machine innovatively uses 2900W camera to accurately take photos and cut products, generate DWG graphics, 500W CCD secondary positioning, automatically correct the cutting position, maximize the efficiency of laser, cut the waterproof film without damaging the product.

-

-

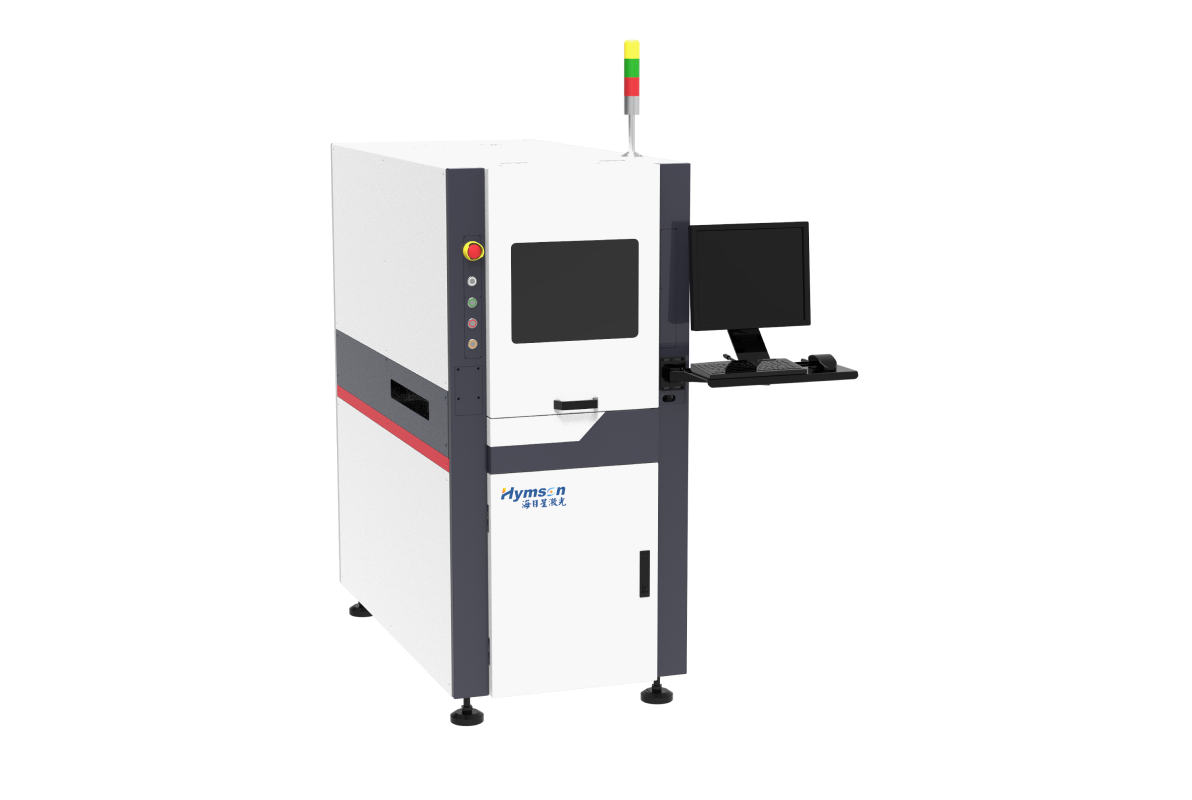

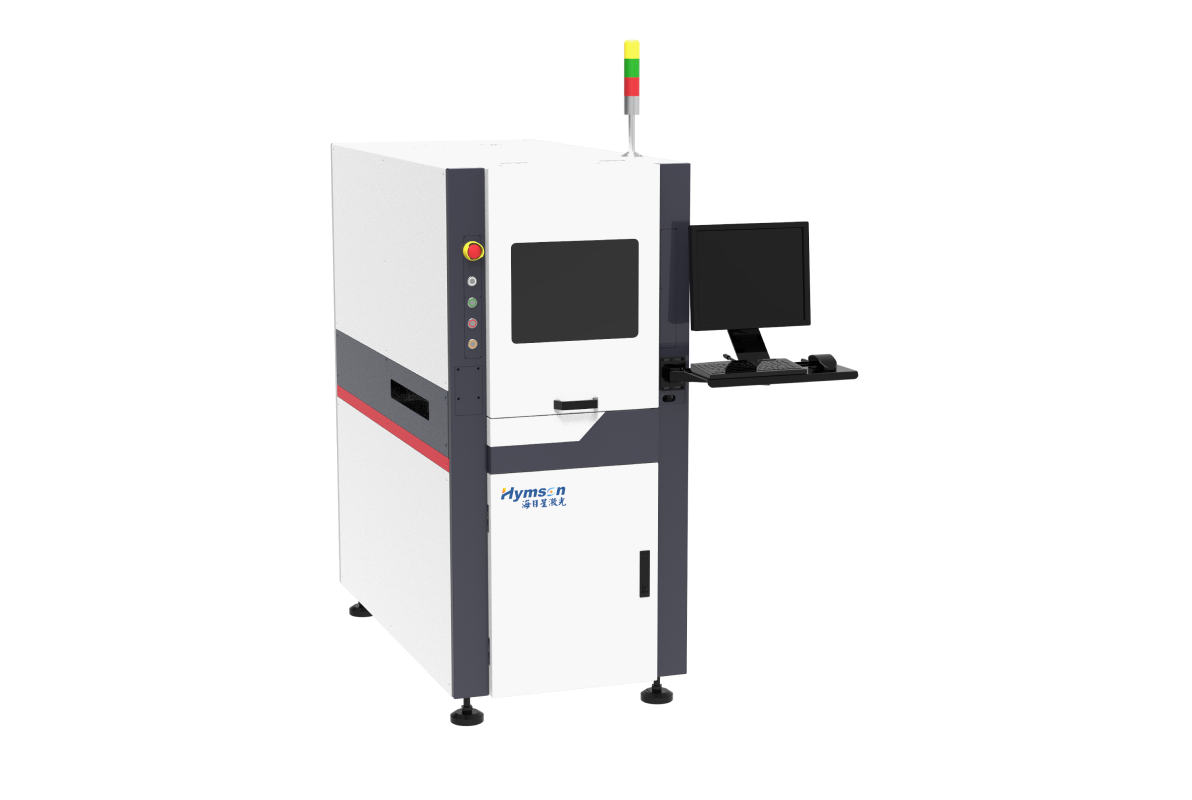

View ProductsFull-automatic Copper Clad Plate Laser Marking Machine

View ProductsFull-automatic Copper Clad Plate Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Fiber laser is adopted, with good beam quality, strong material compatibility and fast processing speed.

-

Standard SMEMA interface and network communication function can communicate with upstream and downstream devices and servers.

-

High-precision CCD vision positioning, automatic offset compensation, and the equipment integrates laser coding and CCD code reading.

-

-

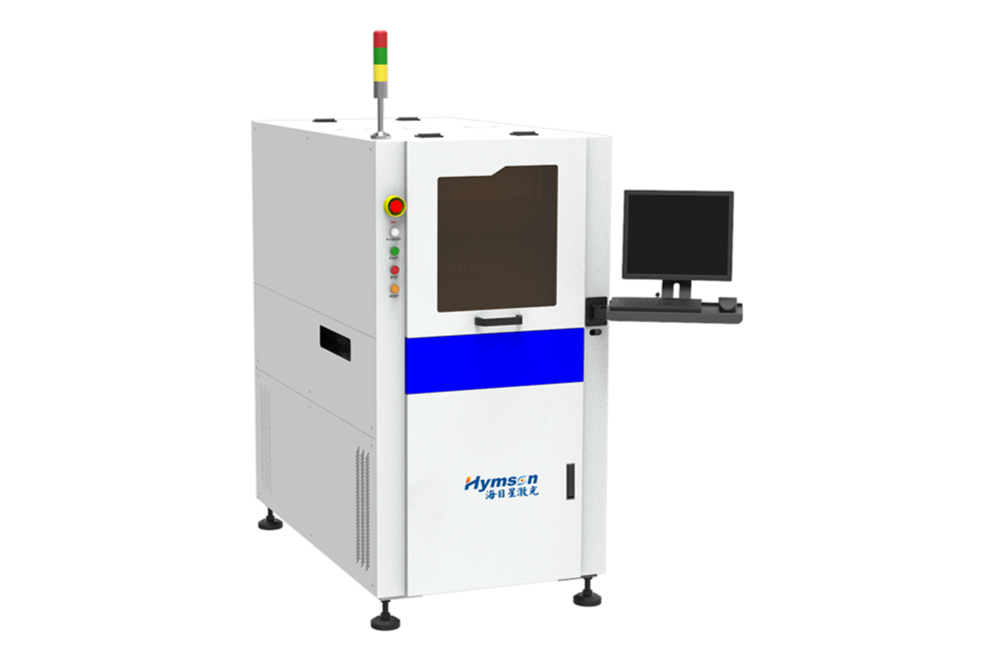

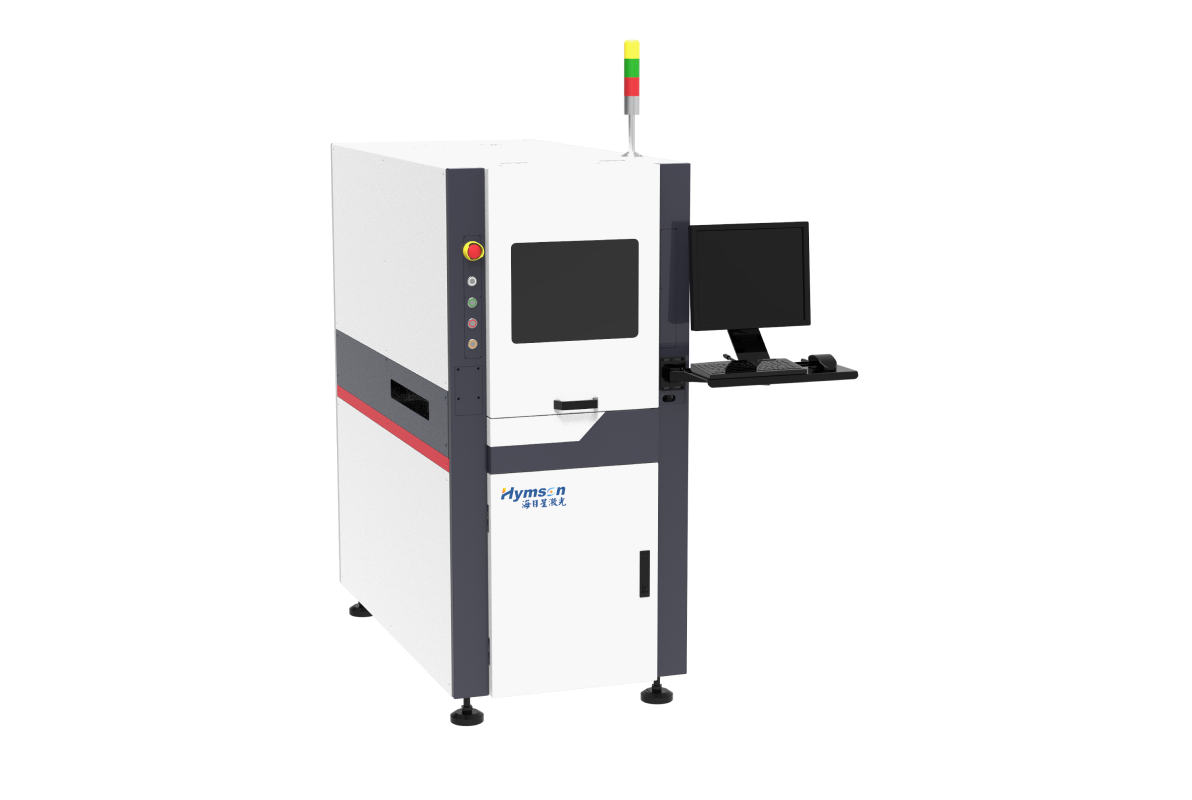

View ProductsAuto PCB Laser Marking Machine

View ProductsAuto PCB Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Can be configured with high-performance CO2, optical fiber, green light and UV laser, and with adjustable power.

-

Easy to operate and can etch various patterns, characters, 2D codes, 1D codes and other contents.

-

Highly intelligent, high precision, strong system stability, true coaxial technology. Can conduct marking and reading immediately, and with faster efficiency.

-

-

View ProductsAutomatic IC Laser Marking Machine

View ProductsAutomatic IC Laser Marking Machine-

The efficiency of single/double head laser marking system has been greatly improved.

-

The support adopts the automatic loading and unloading method of clip or stack, and the loading, marking and detection can be performed separately.

-

Support MES, remote control and data upload; Unmanned, digital workshop system docking.

-

High-precision CCD visual positioning ensures the accuracy of marking position, and confirms the printing content and quality after marking.

-

-

View ProductsAuto PCB Laser Removal Machine

View ProductsAuto PCB Laser Removal Machine-

Equipped with high-performance CO2 laser and UV picosecond laser. The power and frequency are adjustable.

-

The X/Y/Z module with high speed and high precision motion and with side-axis moving platform can be used for large scale machining

-

Linear motor and optical ruler are used to drive the processing platform in a closed loop. Easy to maintain. Equipped with high-precision camera. High positioning accuracy. High removal accuracy

-

Adopt marble precision platform, stable bearing, corrosion resistant, equipped with auto loading&unloading structure, reduce manual operation, and greatly increase production capacity.

-

-

View ProductsPVD Remover

View ProductsPVD Remover-

This machine is applicable to glass surface cleaning, including but not limited to ink removal, PVD removal, etc. Such as camera hole, flash hole of mobile phone, ALS hole of notebook and PVD coating of front and rear cover can be removed

-

The turntable type dual-station processing platform can realize automatic online surface cleaning of dual-station, non-contact processing and pollution-free

-

CCD visual positioning module is used to selectively clean the glass surface. After cleaning, the glass transmittance reaches more than 90%, the glass substrate is not damaged, and the processing accuracy can be controlled within ± 0.02mm

-

-

-

-

View ProductsFull-automatic Copper Clad Plate Laser Marking Machine

View ProductsFull-automatic Copper Clad Plate Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Fiber laser is adopted, with good beam quality, strong material compatibility and fast processing speed.

-

Standard SMEMA interface and network communication function can communicate with upstream and downstream devices and servers.

-

High-precision CCD vision positioning, automatic offset compensation, and the equipment integrates laser coding and CCD code reading.

-

-

View ProductsAutomation TOPCon Laser Doping Machine

View ProductsAutomation TOPCon Laser Doping Machine-

Adapt Hymson independent developed laser device & special optical circle design to BSG laser doping.

-

According to customer requirement design & manufacture equipment to realize high productivity, high precision, high efficiency, lossless doping.

-

Precision visual position, high speed flexible transimission, fragment lower 0.02%

-

-

-

-

View ProductsAuto PCB Laser Marking Machine

View ProductsAuto PCB Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Can be configured with high-performance CO2, optical fiber, green light and UV laser, and with adjustable power.

-

Easy to operate and can etch various patterns, characters, 2D codes, 1D codes and other contents.

-

Highly intelligent, high precision, strong system stability, true coaxial technology. Can conduct marking and reading immediately, and with faster efficiency.

-

-

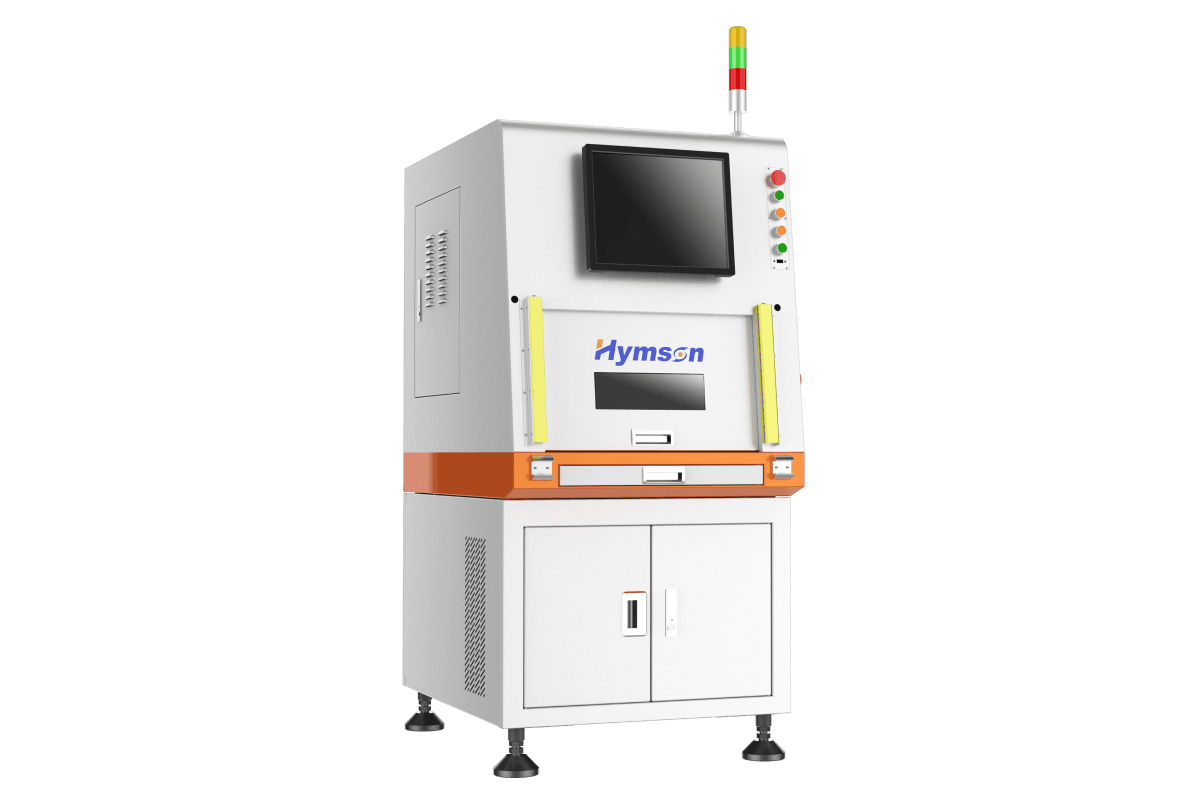

View ProductsDouble Station Uv Laser Marking Machine

View ProductsDouble Station Uv Laser Marking Machine-

Suitable for glass, polymer materials and other objects surface marking, micro - pore processing.

-

Widely used in food, medicine, cosmetics, wires and other polymer material packaging bottle (box) surface marking, punching microhole (_x0001_ aperture _x0001_d< 10μm).

-

Flexible PCB board, LCD, TFT marking, cutting, etc.

-

Metallic or nonmetallic coating removal.

-

-

View ProductsGreen Laser Marking Machine

View ProductsGreen Laser Marking Machine-

Superior beam quality.

-

Fast heat dissipation and stable temperature inside the cavity.

-

Output different wavelength, different power and pulse width.

-

Maintenance-free, continuous use up to 20,000 hours.

-

-

-

-

View ProductsAuto PCB Laser Marking Machine

View ProductsAuto PCB Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Can be configured with high-performance CO2, optical fiber, green light and UV laser, and with adjustable power.

-

Easy to operate and can etch various patterns, characters, 2D codes, 1D codes and other contents.

-

Highly intelligent, high precision, strong system stability, true coaxial technology. Can conduct marking and reading immediately, and with faster efficiency.

-

-

View ProductsMicro LED Intelligent Versatile Laser Removal Equipment

View ProductsMicro LED Intelligent Versatile Laser Removal Equipment-

Being used for Micro LED chip removal, welding and leveling compatible with different sizes of chips and substrates, leveling accuracy up to sub-micron level.

-

The chip glue of Micro LED as small as 5μm is removed by matching micron light spots, without damaging adjacent chips, pads and other layers.

-

Through the self-developed AI integration system, the repair location can be automatically identified to avoid the repair failure caused by misjudgment and ensure product safety.

-

-

View ProductsMicro LED Laser Mass Transfer Equipment

View ProductsMicro LED Laser Mass Transfer Equipment-

Modular design, separation of loading & unloading mechanism and transfer module.

-

Automated wafer replacement using a robotic arm, with an overall equipment accuracy of ±1 μm.

-

Laser control system, High quality optical system, the spot uniformity≥95%.

-

-

View ProductsMini LED Fully Automatic Laser Removal Equipment

View ProductsMini LED Fully Automatic Laser Removal Equipment-

It is used for removing the adhesive material after the Mini LED module is sealed and for dressing the solder pad after the crystallization of each process segment. It is compatible with products of different thicknesses and sizes.

-

With micron - level light spots, it can efficiently remove Mini LED packaging glue of all sizes without damaging adjacent chips and pads. The self - developed chip removal system creates a clean repair environment, significantly boosting the repair yield.

-

-

View ProductsFully Automatic Chip Removal Equipment

View ProductsFully Automatic Chip Removal Equipment-

Coaxial visual positioning system, high-precision positioning chip position

-

Accurate detection of welding pad height trims residual tin paste on the welding pad without damaging the welding pad

-

Flexibly select laser or mechanically remove chips

-

-

-

Inquiry

Inquiry

Click to inquiry

Customer service

Customer Service

Contact us