Solutions

Hymson Laser provides high-speed, high-precision, high-efficiency, and automatic sheet metal solutions for industry customers to meet the sheet metal processing needs of different materials and thicknesses.

- Sheet Metal Laser Cutting

- Tube Laser Cutting

- 3D Five-axis Cutting

- Automatic Production Line

- Laser Welding Solution

-

Solution of Sheet Metal Laser Cutting

Provide high-speed, high-precision and high-efficiency laser cutting solutions for metal sheets.

Get the solution-

Construction Machinery

Construction Machinery -

Metal Furniture

Metal Furniture -

Cabinet

Cabinet -

Elevator Manufacturing

Elevator Manufacturing

-

High Efficient ProductionHigh-speed, high-precision, high-efficiency laser cutting production and processing of sheet metal parts in various industries

-

Safety and Eco-friendlyIntelligent zoned and segmental ventilation with High-intensity dust extraction,high efficiency of air extraction and dust removal, health and eco-friendly.

-

Modular designThe high-quality matching of the whole machine can quickly respond to market demand under the premise of ensuring high strength and high reliability of the machine tool.

-

-

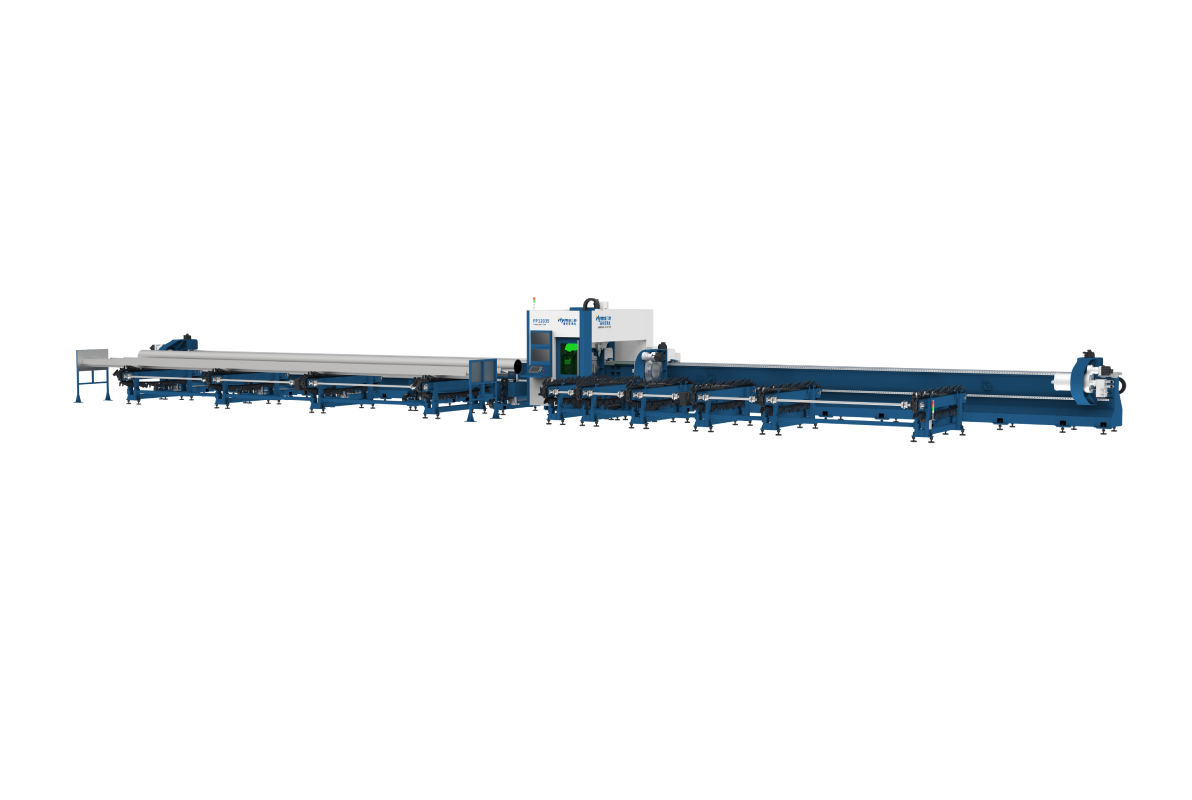

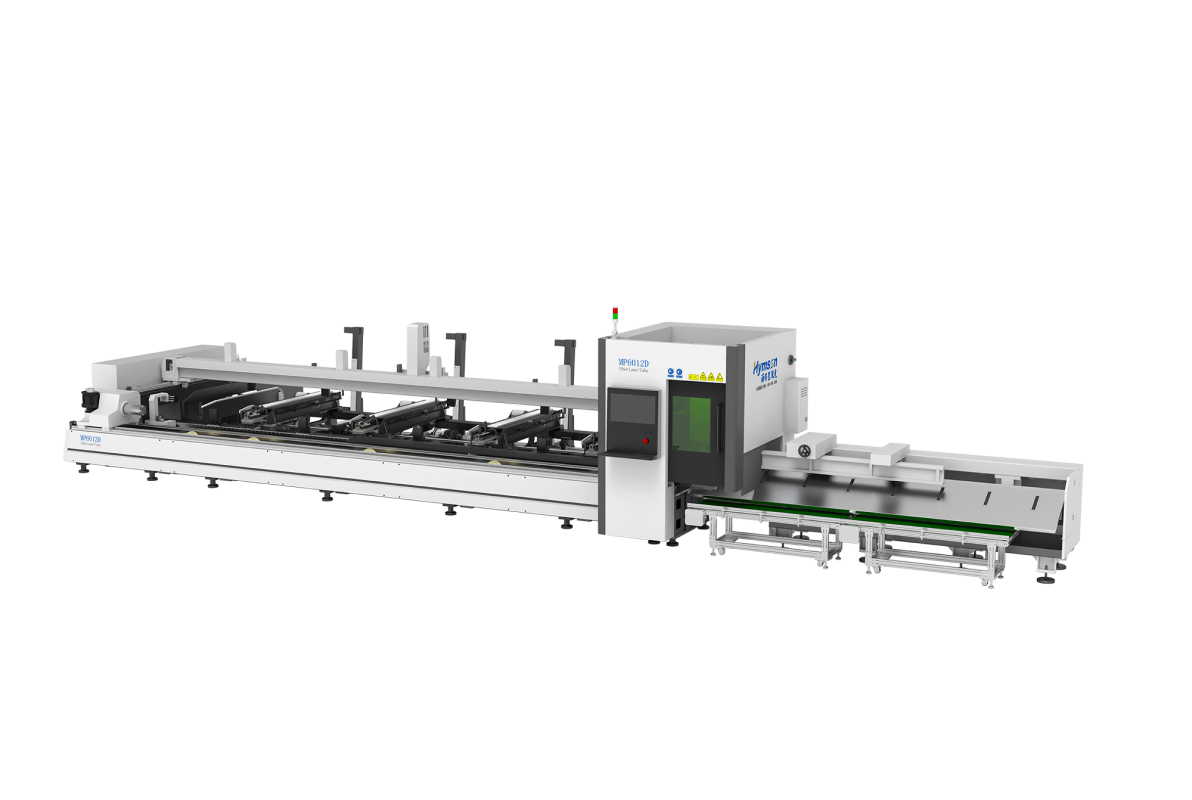

Solution of Tube Laser Cutting

Provide high-volume, high-speed, high-precision and high-efficiency tube processing solutions for metal tubes and profiles.

Get the solution-

Pipe processing

Pipe processing -

Fitness Equipment

Fitness Equipment -

Oil Pipeline

Oil Pipeline -

Bridge Construction

Bridge Construction

-

High Degree of AutomationEquipped with Full-automatic loading system,achieve automatic production.

-

Customized Tubes CutterProvide high-speed and high-precision cutting of long and heavy pipes, large pipes, and various types of pipes in the heavy industry.

-

High PerformanceProfessional pipe cutting machine with outstanding clamping force, wide range of processing pipe diameters and various types, effectively guaranteeing production and processing.

-

-

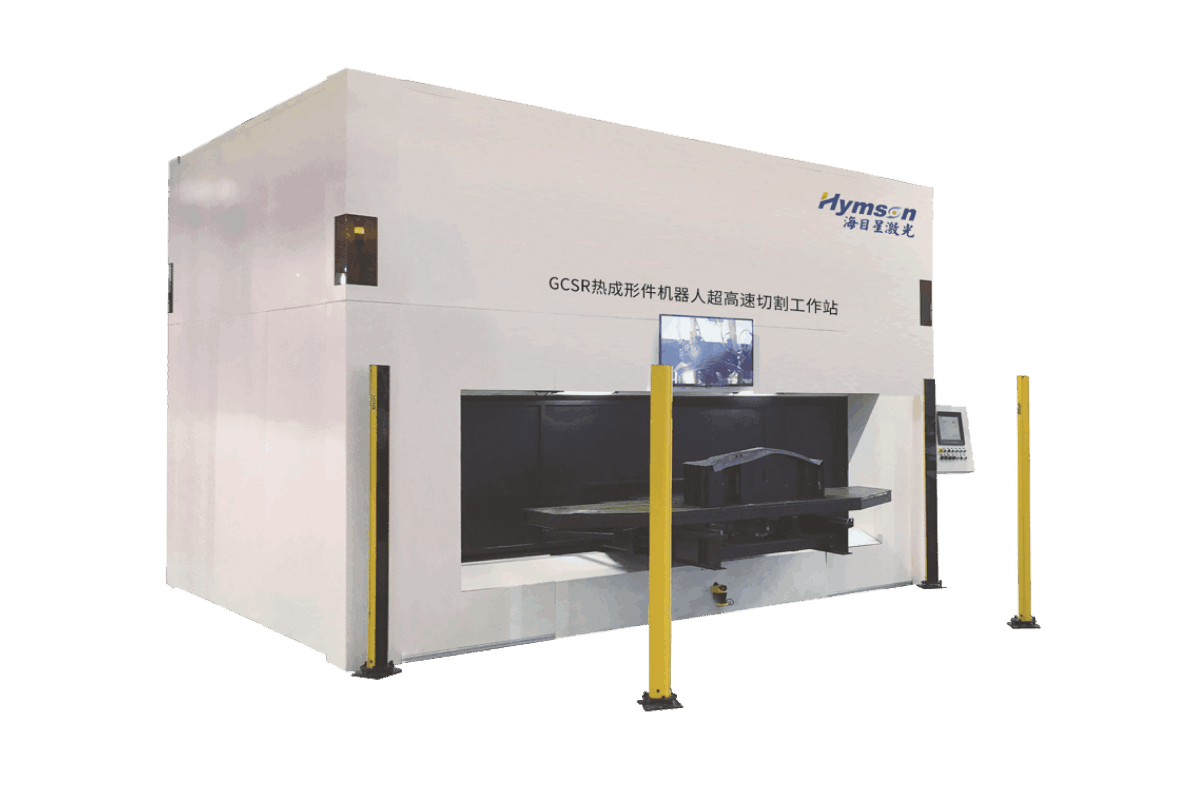

3D Five-axis Cutting solution

Hymson's 3D laser cutting solution is used for efficient and precise cutting of various heterogeneous sheet metal parts of the car body to achieve flexible production.

Get the solution-

Automobile sheet metal parts

Automobile sheet metal parts

-

High PrecisionThe second calibration of the robot and the motion interpolation algorithm can effectively improve cutting accuracy.

-

Multi-axis LinkageMulti-axis linkage realizes complex trajectory, improves production cycle and reachable range, and realizes high-precision and high-efficiency cutting of complex workpieces.

-

Dual robot workstationsCan be equipped with dual robot workstations to realize dual-station material change and linked cutting at the same time, the cutting efficiency has greatly improved.

-

-

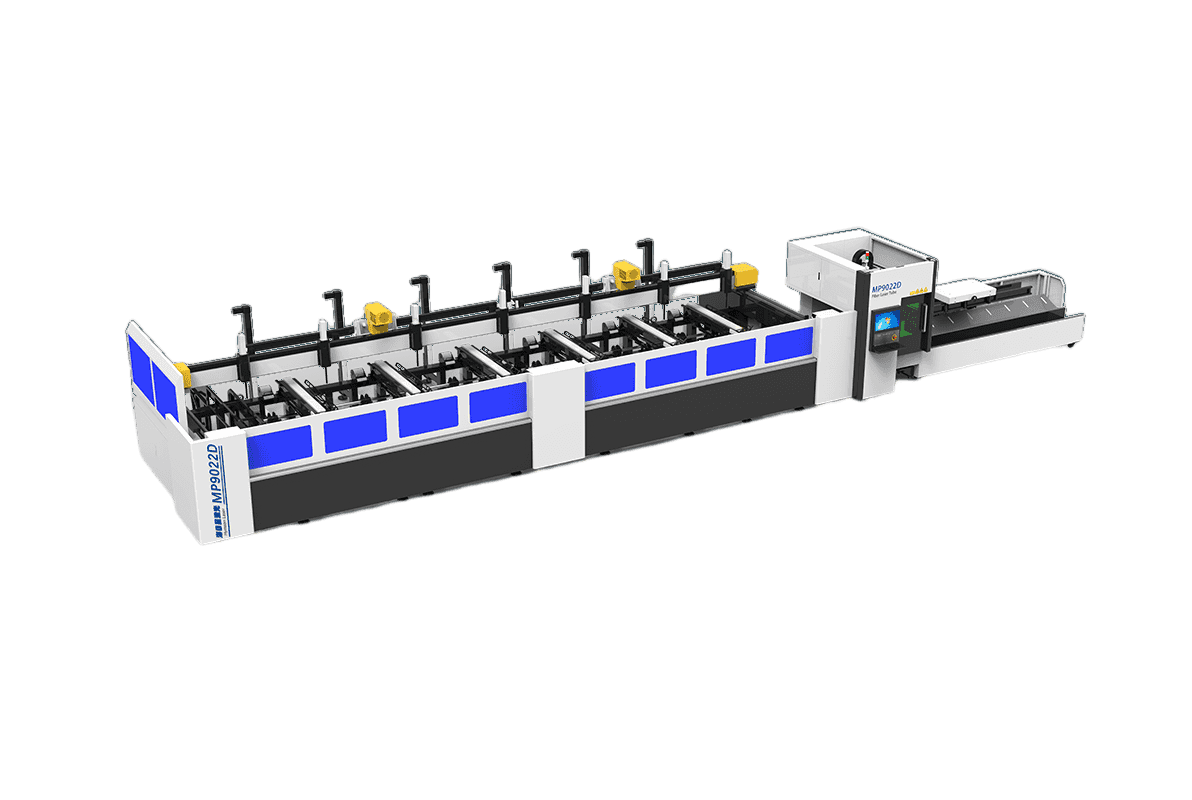

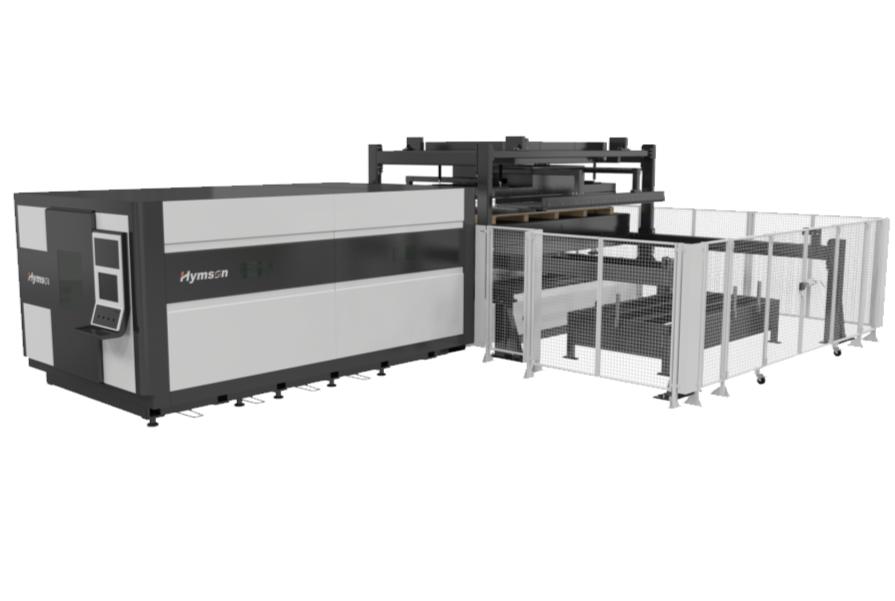

Automatic Production Line Solution

Fully automatic laser cutting solutions.

Get the solution-

Stainless Steel Coil

Stainless Steel Coil -

Smart Factory MES

Smart Factory MES

-

SafetyThe automatic system is completely by program and requires no human intervention.

-

Production CapacityA factory with an automatic system would only require additional machines, no additional labor.

-

ConsistencyThe automatic system completes each production process in an orderly manner according to the settings, effectively maintaining consistency.

-

High EfficiencyLaser cutting flexible production line is an effective solution to reduce production cost and improve production efficiency.

-

Fast SpeedAutomatic loading and unloading will reduce 35% material loading and unloading time compared to a single operator, and the automatic system can be continuous used in a long time.

-

-

Laser Welding Solution

Hymson is committed to providing users with efficient laser welding solutions.

Get the solution-

Robot Welding

Robot Welding -

Handheld Welding

Handheld Welding

-

High EfficiencyFast welding speed, concentrated energy, beautiful weld seam, no secondary grinding

-

High QualityHigh quality and stable welding, large depth, small deformation,stable performance

-

Automatic WeldingUniversal robot welding and welding platform, which can realize automatic welding and improve welding efficiency.

-

Main Products

Sheet-metal working is one of most important application field

-

Sheet Metal Laser Cutting

-

Tube Laser Cutting

-

3D Five-axis Cutting

-

Automatic Production Line

-

Laser Welding Solution

-

-

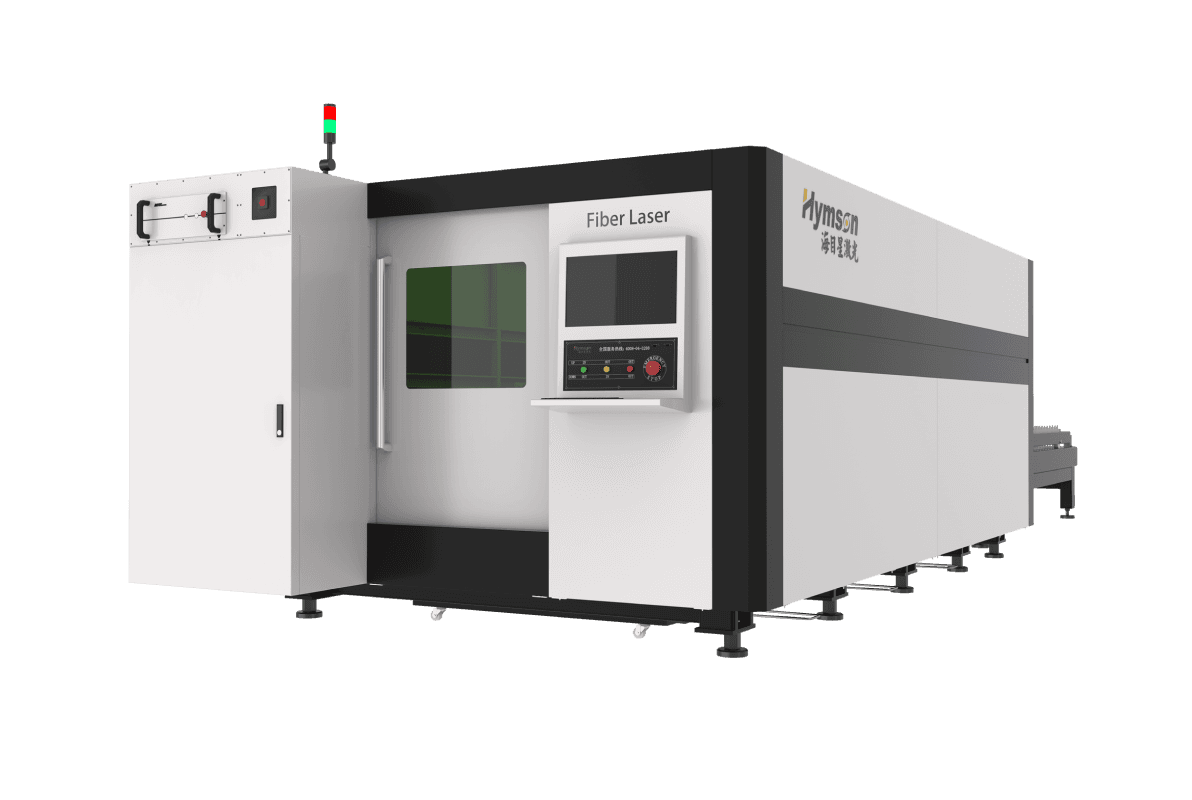

View ProductsHF-C Series Fiber Laser Cutting Machine

View ProductsHF-C Series Fiber Laser Cutting Machine-

Modular design and quality matching of the whole machine.

-

The mortise and tenon joint structure ensure the long-term stability of the machine.

-

High-strength drawn aluminum crossbeam design for superior dynamic performance.

-

Fully encircled machine with double platform,safe and efficient production.

-

-

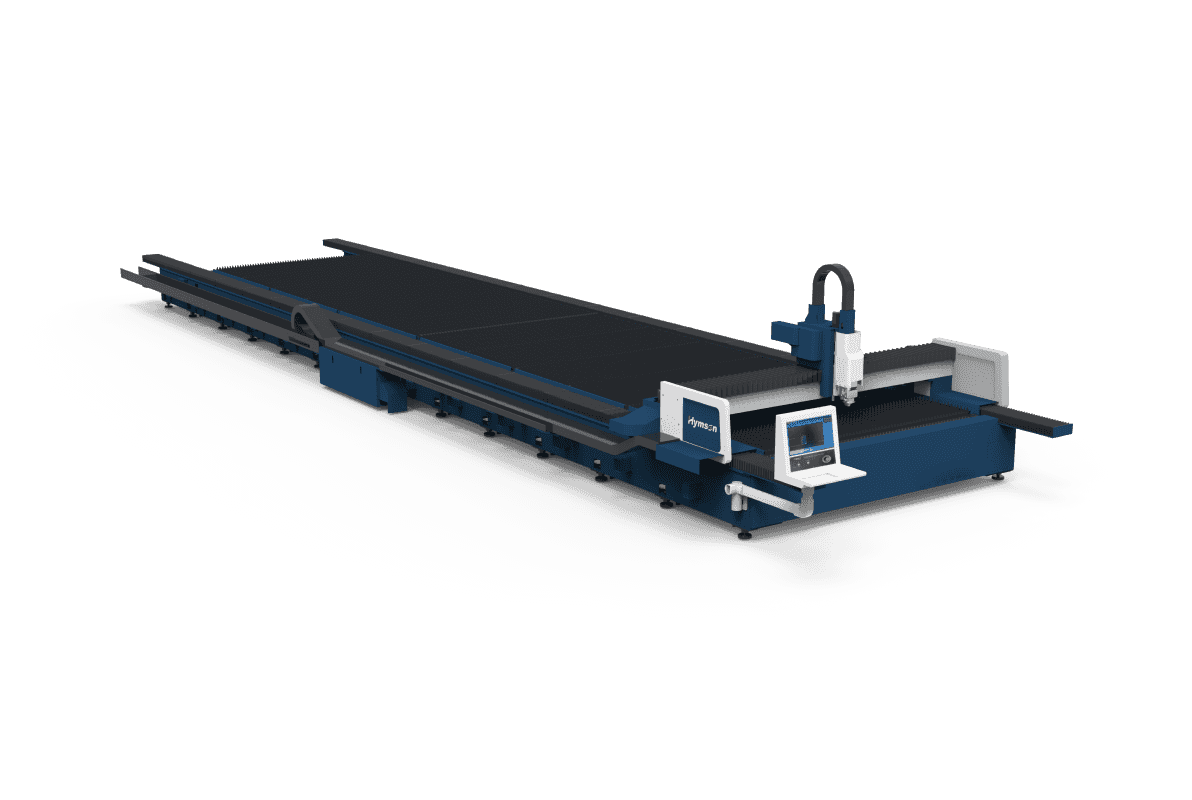

View ProductsHF-T Series Fiber Laser Cutting Machine

View ProductsHF-T Series Fiber Laser Cutting Machine-

Extra-long and extra-wide models can be customized, and the processing area can be freely chosen.

-

Movable operating platform for easy operation (up to 16 m).

-

High efficiency and unique extraction structure, outstanding effect of smoke and dust removal and heat removal

-

Brand New bus control system, flexible and free application, No-sense Piercing, high efficiency in cutting thick sheets.

-

-

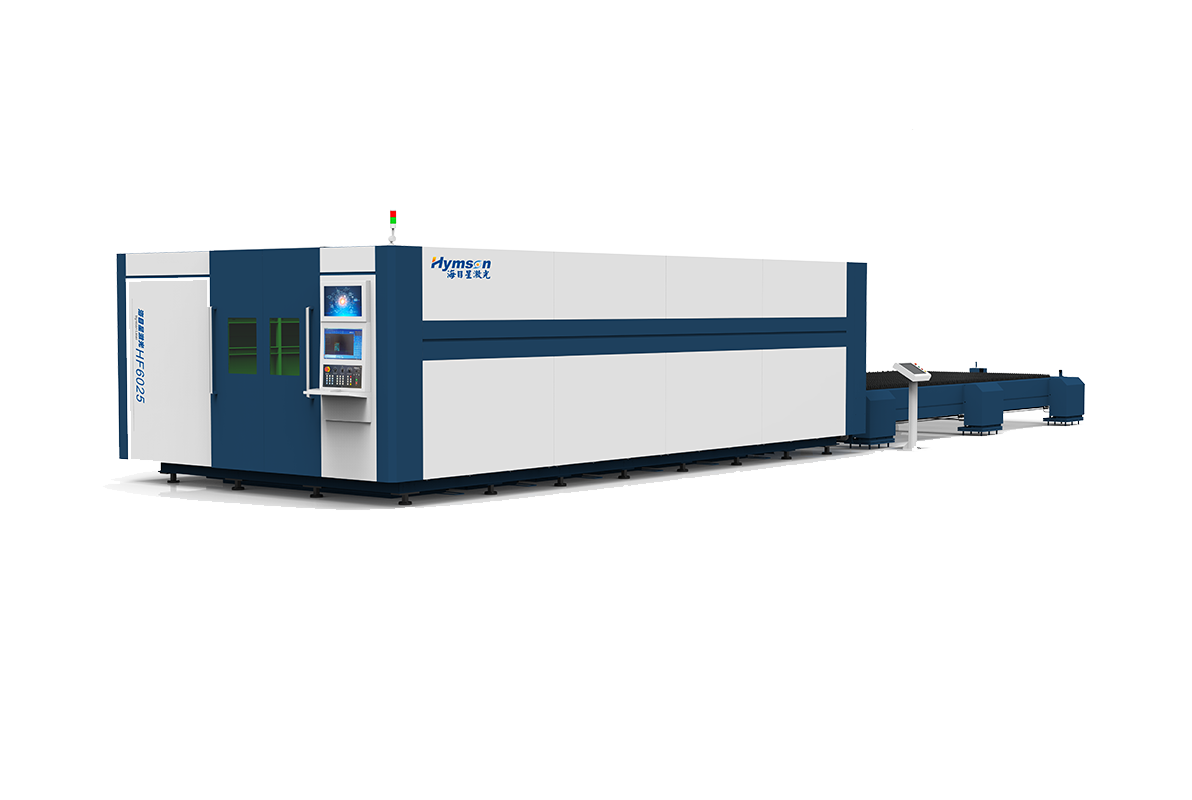

View ProductsHF-H Series Fiber Laser Cutting Machine

View ProductsHF-H Series Fiber Laser Cutting Machine-

Workbench adopt exchange + rear hydraulic lift type, high load.

-

New upgrade of Hymson HF-D series laser cutting machines.

-

High degree of automation to meet the demand of large quantities of medium and thick plates automatic cutting.

-

Can be equipped with automatic warehousing, full-automatic loading/unloading system, etc. for extension of automatic production line.

-

-

View ProductsHF-D Series Fiber Laser Cutting Machine

View ProductsHF-D Series Fiber Laser Cutting Machine-

Wide applicability, suitable for cutting multiple types and different thicknesses of sheets.

-

High speed, high precision, high dynamic performance fiber laser cutting machine for industry common use.

-

Can be equipped with automatic warehousing, full-automatic loading/unloading system, etc. for extension of automatic production line.

-

Industry-leading dynamic compensation technology for thermal effect, effectively ensuring long-term stable use of the machine and guaranteeing cutting accuracy.

-

-

View ProductsHP30035 SERIES SPECIAL PROFILE CNC LASER METAL CUTTING MACHINE

View ProductsHP30035 SERIES SPECIAL PROFILE CNC LASER METAL CUTTING MACHINE-

The machine body is welded with high-strength plates, to ensure that the machine tool has stable structure and it can stably operate for a long time.

-

Processing of the machine body adopts high-temperature treatment to maximum eliminate internal stress generated by the material and welding, and ensure high-strength, high-accuracy, and high tolerance.

-

The beam is made of high-intensity steel, which can reduce stress deformation, and ensure stable operation.

-

This part adopts high-intensity negative face adjustable support structure, which can be used to cut the material with the width of 200-3000mm.

-

-

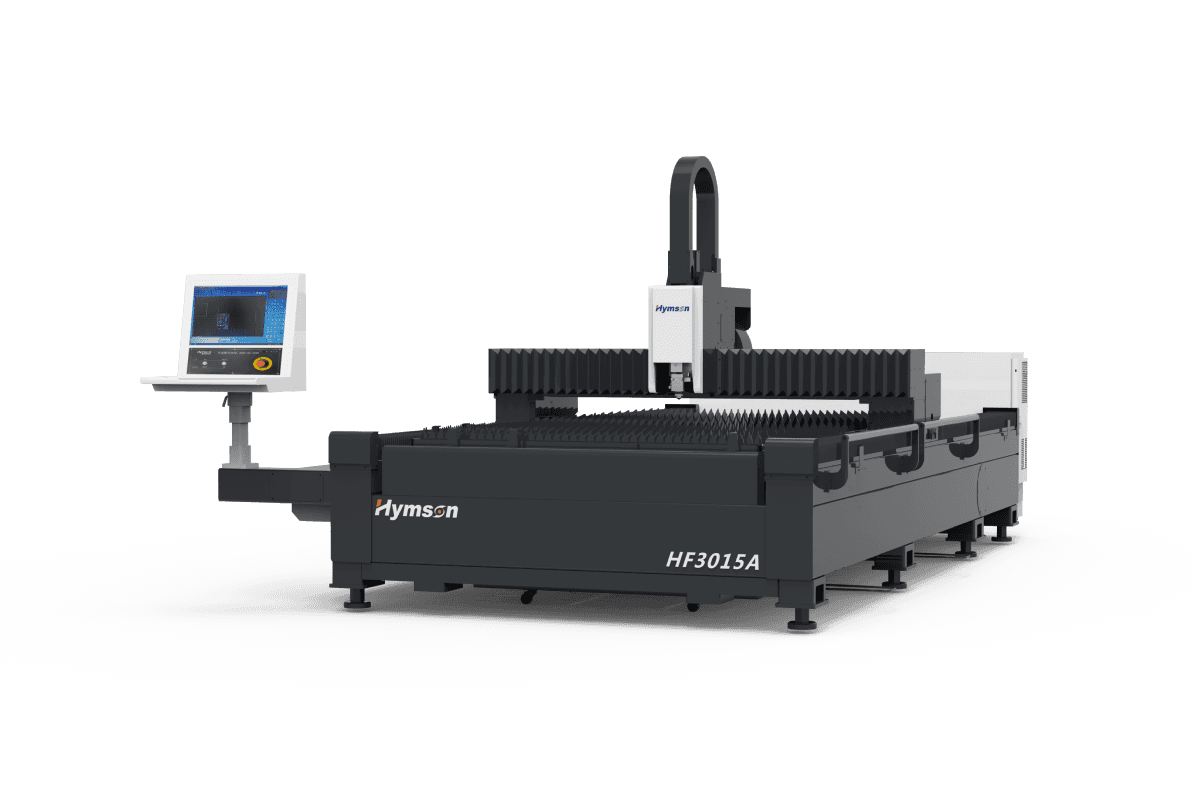

View ProductsHF-A Series Fiber Laser Cutting Machine

View ProductsHF-A Series Fiber Laser Cutting Machine-

Mobile operating table, for easy operation.

-

Flexible application of single table, small footprint and high availability.

-

The mortise and tenon joint structure ensure the long-term stability of the machine.

-

Master6000S bus control system, deeply developed, easy to operate, intelligent and efficient.

-

-

-

-

View ProductsCustomized Laser Tube Cutting Machine

View ProductsCustomized Laser Tube Cutting Machine-

Professional chucks with large clamping force and fully sealed rear chucks with good dustproof effect.

-

Special for long tube and heavy tube cutting, high cutting precision, can achieve "zero length of cutting residue".

-

The auxiliary support adopts servo follow-up to effectively prevent the pipe from swaying from side to side when rotating at high speed,thus guarantees the precision of turning during cutting.

-

Full penetration three chucks, four chucks collaborative linkage, can achieve real zero cutting residue, improve material utilization.

-

-

View ProductsAutomatic Laser Tube Cutting Machine

View ProductsAutomatic Laser Tube Cutting Machine-

Automatic high standard laser tube cutting machine, which is specific and common use in industry and suitable for intensity continuous production tube processing

-

High degree of automation, standard with Hymen patented fully automatic loading system. High success rate of loading and dividing feeding, the advantage of tube changing beat is obvious, strong stability, industry leading.

-

Extensible automatic tube laser cutting production line,highly continuous, stable, accurate and fast production,greatly improve production efficiency and reduce costs.

-

Wide range of tube diameter can be processed , wide range of stroke, suitable for high-speed and high-precision cutting of multiple types of pipes.

-

-

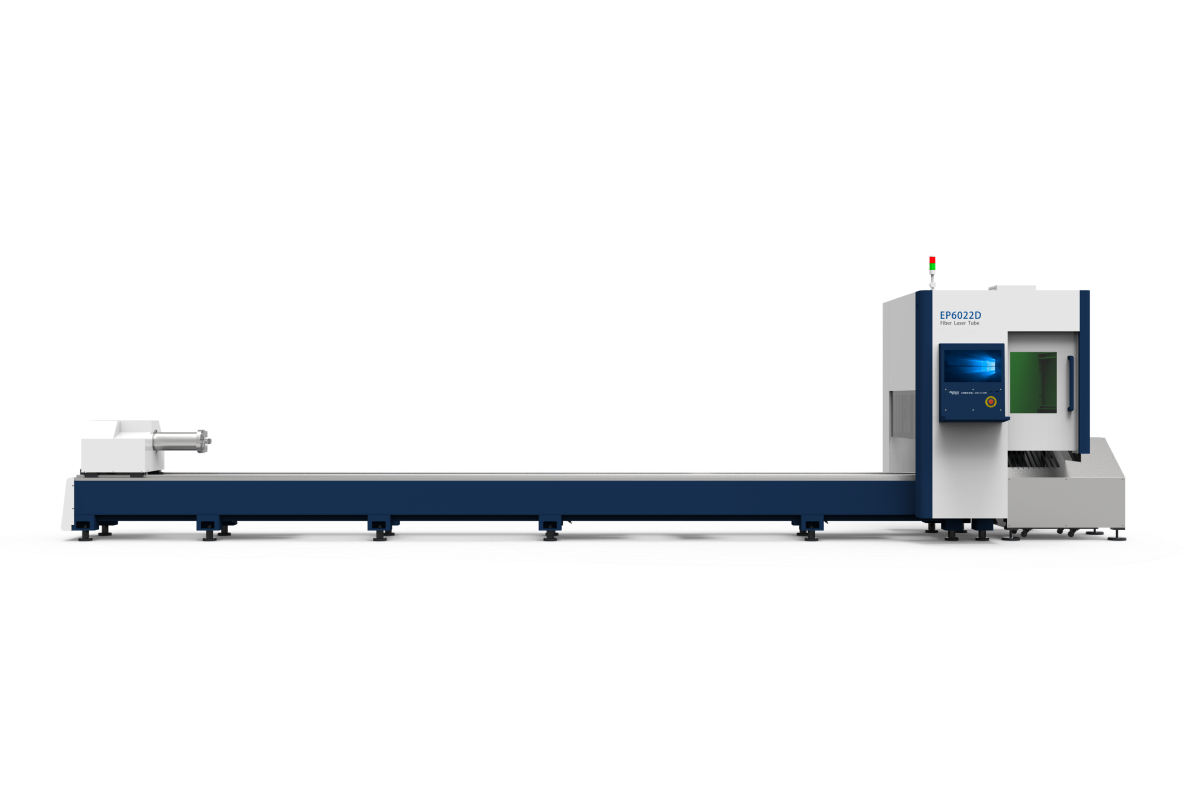

View ProductsStandard Laser Tube Cutting Machine

View ProductsStandard Laser Tube Cutting Machine-

Professional tube cutting, high precision, high speed cutting and fast acceleration.

-

Wide range of processed pipe diameters and types: Circular Tubes:Φ10mm~Φ220mm Square Tubes and Rectangular Tubes:□10mm~□150mm

-

Automatic pneumatic fully enclosed chuck with clamping force up to 300kg, industry leading.

-

High-speed, high-precision modules to improved performance and processing accuracy.

-

-

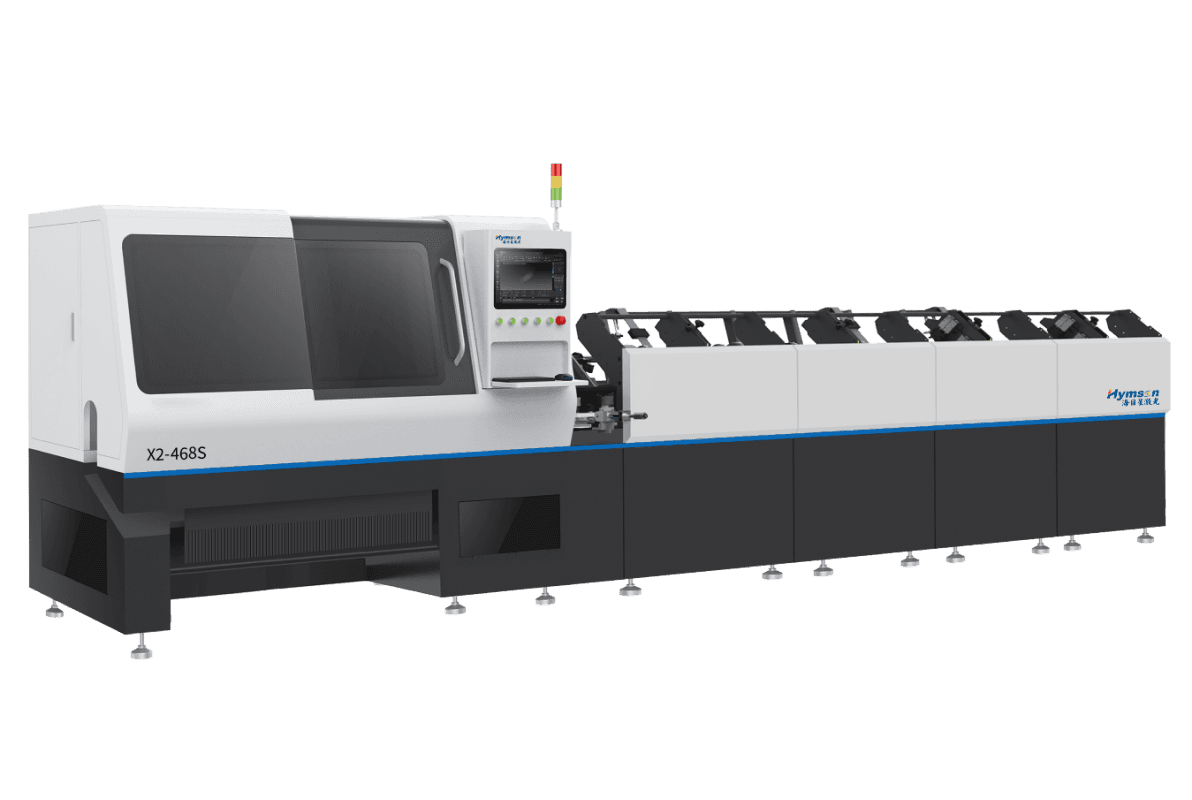

View ProductsHigh-speed Laser Tube Cutting Machine for Small Tubes

View ProductsHigh-speed Laser Tube Cutting Machine for Small Tubes-

Tube Specification:Circular Tubes : Φ15mm~Φ85mm;Square Tubes and Rectangular Tubes:□15x15mm-□60x60mm.

-

Superb applicability, cutting off, hole cutting, bevel cutting can be satisfied.

-

Fast machining speed! Acceleration up to 1.2g.

-

Positioning Accuracy of Cut Product: 0.01mm, Accuracy of Mass Cutting ≦±0.15mm.

-

-

View ProductsS6012 SERIES FIBER LASER TUBE CUTTING MACHINE

View ProductsS6012 SERIES FIBER LASER TUBE CUTTING MACHINE-

The new side-hanging structure, automatic feeding mechanism, all-round breakthrough of processing efficiency.

-

Integral type precision chuck with standard dual-roller clamping jaw,highly improve the cutting accuracy.

-

Chuck stroke up to 120mm, processing range: round pipe 10-120mm; Square tube 10-80mm.

-

The brand new FSCUT 3000 professional tube cutting system integrates multiple tube cutting functions.

-

-

View ProductsProfessional Laser Tube Cutting Machine

View ProductsProfessional Laser Tube Cutting Machine-

Professional laser cutting machine with large range of pipe diameters and many types of processing, strong applicability.

-

The pneumatic, fully sealed, integral type chuck is more stable,with large clamping force, high machining precision and prominent effect of dust prevention,leading the industry.

-

Tube follow-up auxiliary support, effectively guarantee cutting accuracy.

-

Standard servo follow-up unloading, more accurate and efficient.

-

-

-

-

View ProductsHF-TU Series

View ProductsHF-TU Series-

Laser cutting for metal coils.

-

Integrated automatic of loading, uncoiling, leveling, feeding, cutting and unloading.

-

Real-time in-line cutting, simultaneous cutting and feeding, continuous production and processing.

-

-

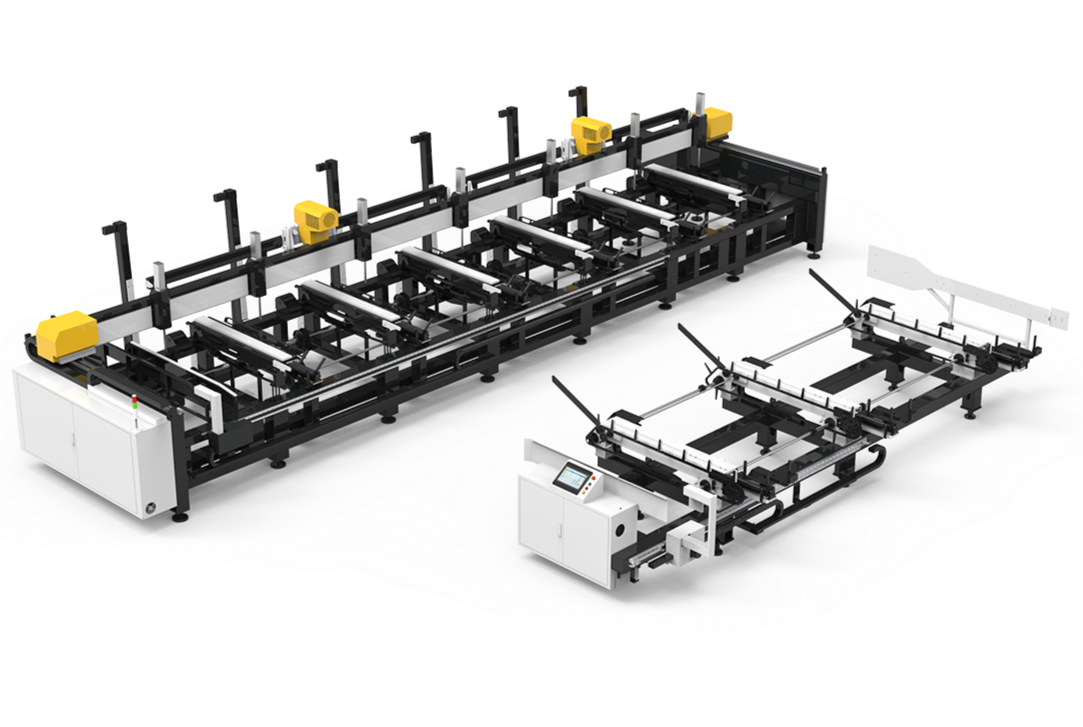

View ProductsAutomatic Loading System for Pipe Cutting

View ProductsAutomatic Loading System for Pipe Cutting-

Professional automatic loading and unloading of various types of pipes such as square tubes, circular tubes, rectangular tubes and profiles such as I-beams and groove steel.

-

Fully automatic loading and unloading system can effectively improve production safety without increasing manual labor, reducing personnel work intensity and labor cost.

-

The automatic loading mechanism adopts independent control system unit, which can work independently and synchronously, greatly improve the production efficiency, with simple and clear interface, convenient and quick operation.

-

Automatic continuous loading, automatic continuous feeding, intelligent follow-up discharging, automatic finished product conveying, ultra-economical to complete the production work of large quantities of different specifications of tubes all day, saving material and labor costs and improving efficiency benefits.

-

-

View ProductsAutomatic Loading and Unloading System for Sheet Cutting

View ProductsAutomatic Loading and Unloading System for Sheet Cutting-

Flexible Manufacturing System is an effective solution to reduce production cost and improve production efficiency. Using this intelligent automation system will gain a better advantage in the market competition.

-

Automatic loading and unloading will reduce 35% material loading and unloading time compared to a single operator, and the automatic system can be continuous used in a long time, with a variety of materials and thicknesses that can be discharged and finished according to production requirements automatically.

-

The automatic system completes each production process in an orderly manner according to the settings, effectively maintaining consistency. On the other hand, in the case of manual operation, the time between each work cycle varies according to the human status.

-

A factory that relies on manual labor to load and unload materials would require additional machines in order to increase production, as well as additional operators, whereas a factory with an automatic system would only require additional machines, no additional labor.

-

-

Partner

Hymson dedicated to optimize production efficiency and energy utilization with high efficiency and stablization manufacturing equipment for partner