-

Hymson Laser

-

Solutions

-

Transports

Solutions

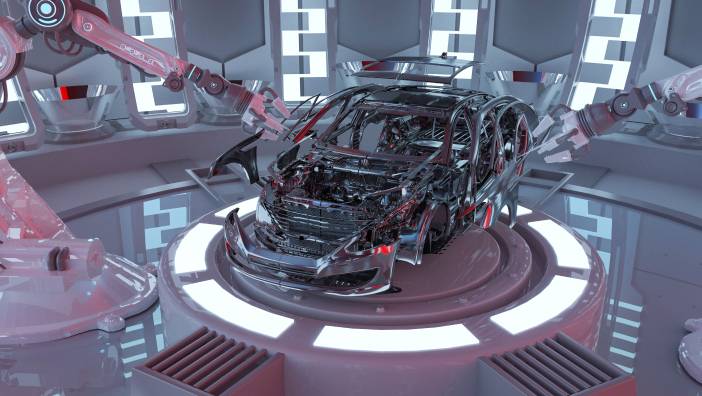

Modern transportation tends to be convenient and smooth, economical and efficient, green and intensive, intelligent and advanced, safe and reliable, and so on. Hymson, as a laser and automation equipment integrated solution provider, provides a series of intelligent, low-cost, safe and reliable manufacturing solutions in the field of transportation.

- Body Sheet Metal Processing

- Automobile Electronic Module

- Automotive Display Module Solution

- Laser Plastic Welding

-

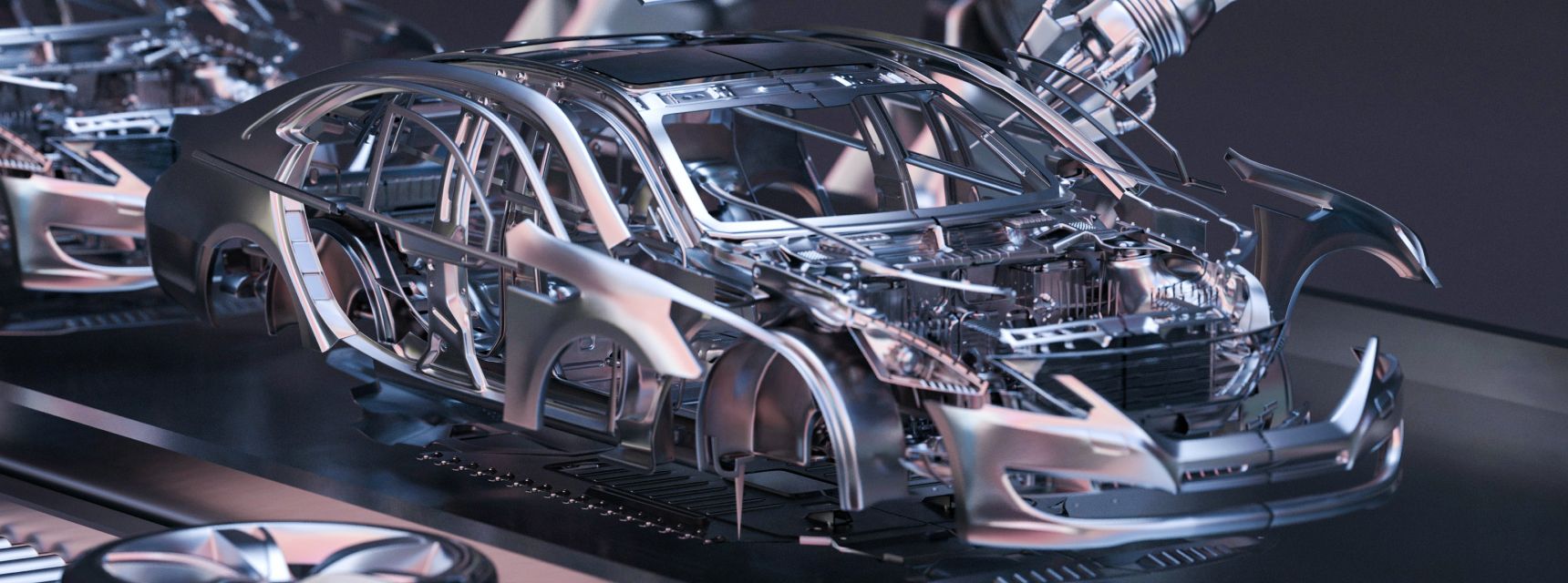

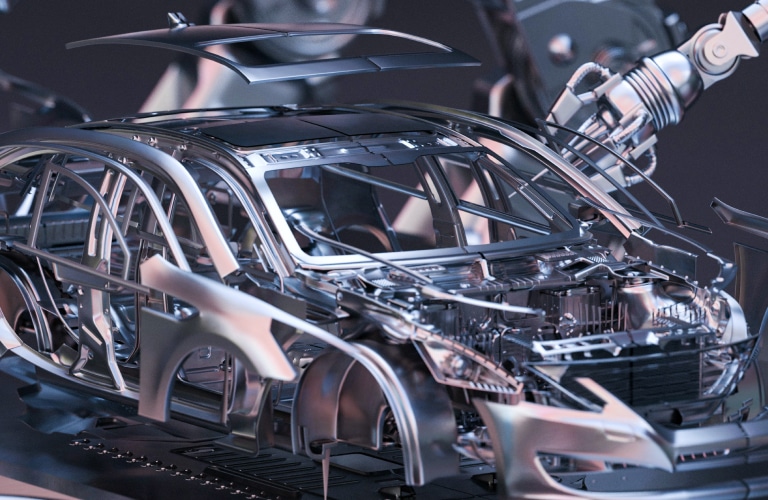

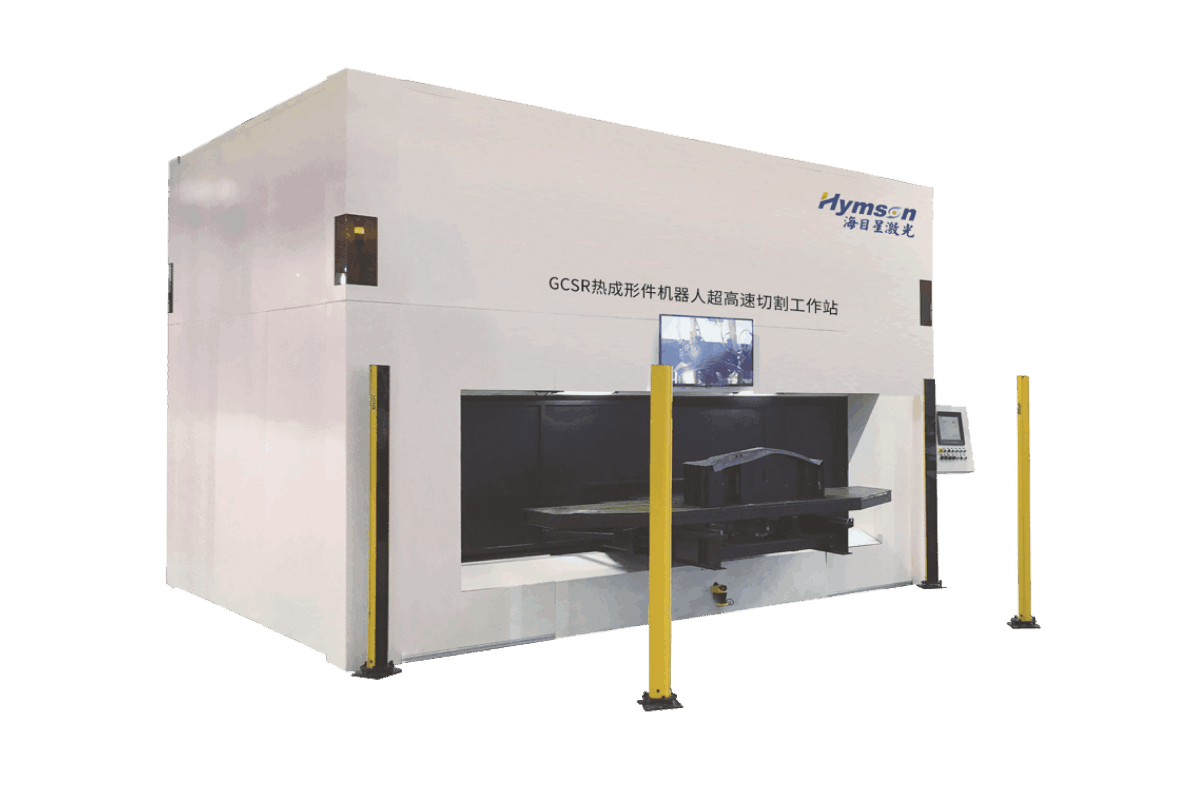

Intelligent Solutions for The Body Sheet Metal Processing Industry

Hymson's 3D laser cutting solution is used for efficient and precise cutting of various heterogeneous sheet metal parts of the car body to achieve flexible production.

Get the solution-

Body Sheet Metal Processing

Body Sheet Metal Processing

-

Secondary CalibrationThe second calibration of the robot improves the positioning accuracy and the cutting efficiency.

-

Motion Interpolation AlgorithmMotion interpolation algorithm, improve the precision of small circle cutting and the cutting quality.

-

Multi-axis LinkageThrough the development of multi-axis linkage function of the robot arm, it can realize high efficient cutting of complex workpieces and easily meet diverse needs.

-

-

Automobile Electronic Module Scheme

The automotive electronics industry is upgrading and iterating towards higher standards and lower costs. The technology application accumulation of Hymson for many years has provided many intelligent and high-standard production solutions for manufacturing automotive electronics.

Get the solution-

High precisionAdopts high-precision visual positioning system.

-

High qualityDifferent types of lasers can be equipped.

-

High efficiencyFull-line automatic production realizable.

-

-

Automotive Display Module Solution

Hymson's innovative process is widely used in automotive chips, instrument displays, central control screens, power semiconductors, automotive electronics and other products, providing laser and automation integrated solutions for the innovation of the automotive screen industry.

Get the solution-

High-performance lasersSelf-developed advanced laser, good beam quality.

-

Ultra-high machining accuracyHigh-precision micron-level motion platform integration to achieve micro-nano processing level.

-

Intelligent control systemFully automatic intelligent program is simple to set, stable with accuracy and high efficiency.

-

Autonomous optical designThe self-developed optical design capabilities can meet the needs of different application scenarios and form core competitiveness.

-

-

Laser Plastic Welding

Suitable for automotive cameras, radar housings, interior and exterior trim components, balancing weather resistance and lightweight design to support smart vehicle manufacturing.

Get the solution-

Automotive Exterior Trim (Parts)

Automotive Exterior Trim (Parts) -

Automotive Interior Trim (Parts)

Automotive Interior Trim (Parts) -

Oil seperator

Oil seperator

-

Lightweight DesignEnables welding of thin-walled structures, making it simple and quick to help reduce vehicle weight and enhance energy efficiency.

-

Environmental ResistanceWelds are highly weather-resistant and can withstand harsh environments, including vibrations and temperature variations.

-

Process FlexibilitySupports welding on three-dimensional curved surfaces with deep closed-loop control, compatible with various types of plastics, accommodating diverse mass production needs.

-

Main Products

Develop new production for transportation.Set up lighter, smarter and safer transportation production.

-

Body Sheet Metal Processing

-

Automobile Electronic Module

-

Automotive Display Module Solution

-

Laser Plastic Welding

-

-

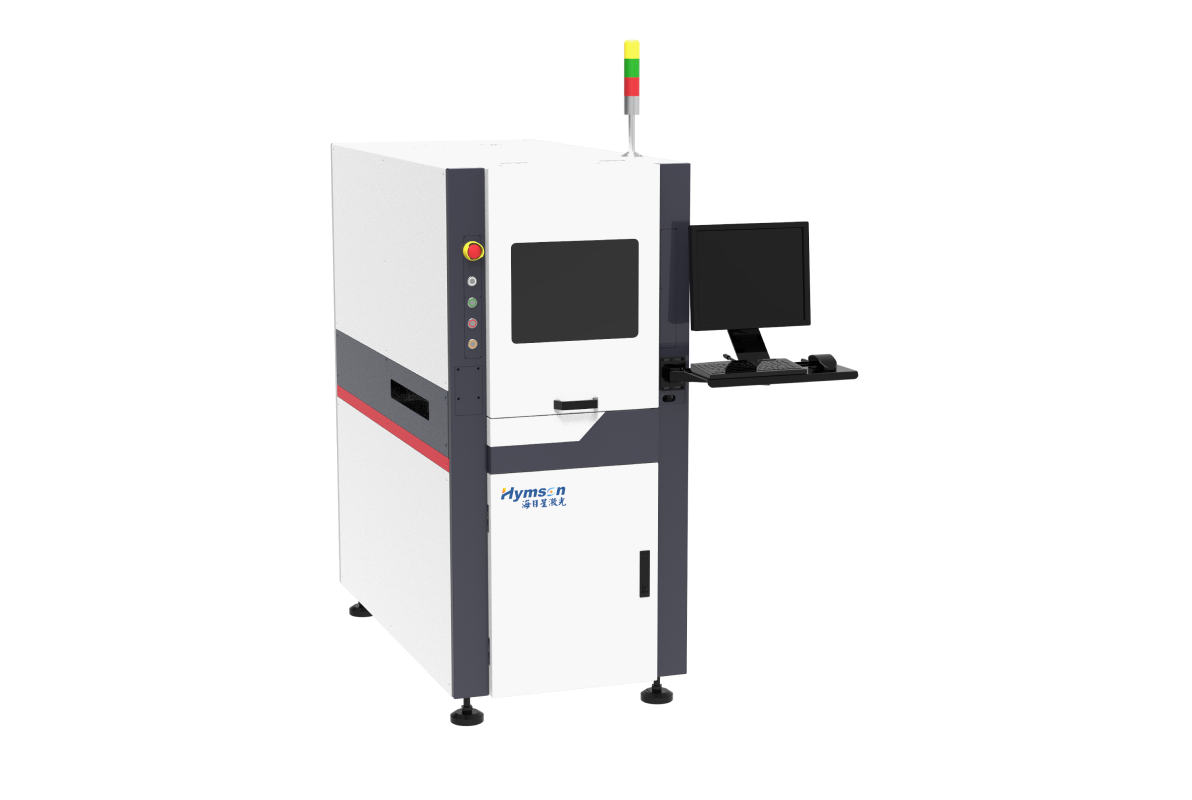

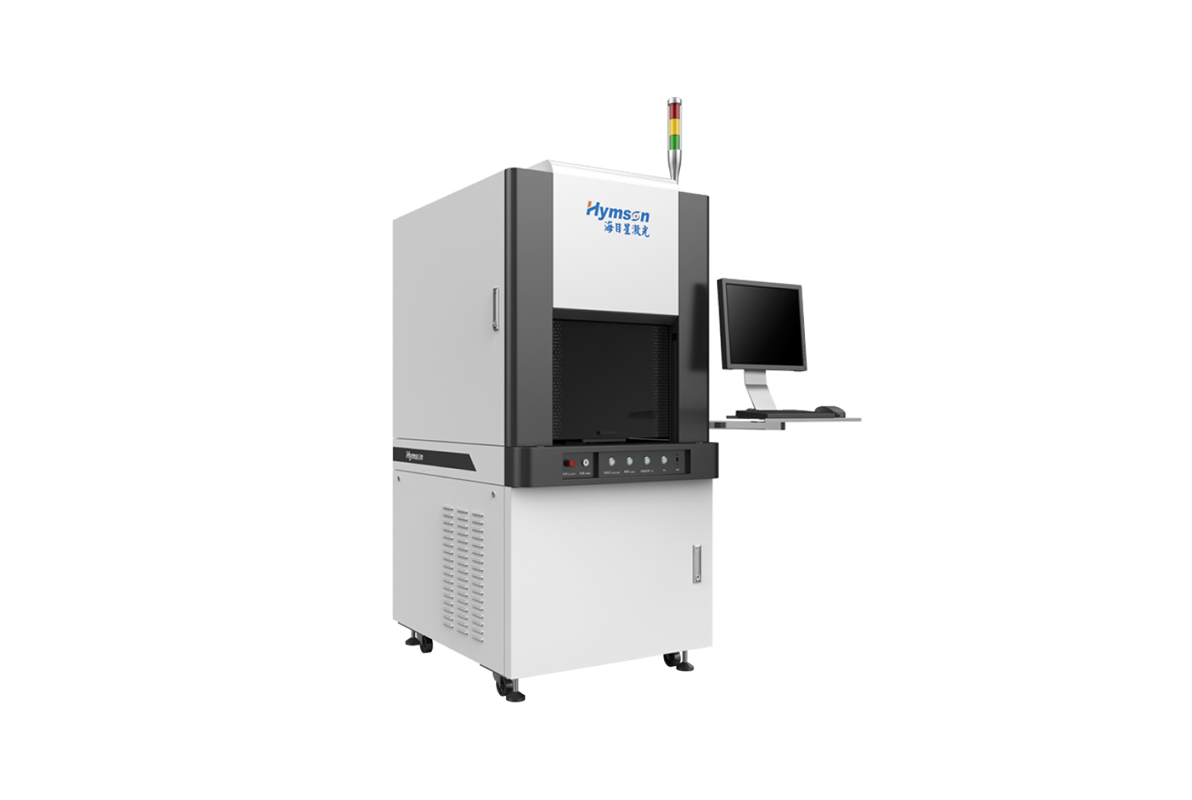

View ProductsAuto PCB Laser Marking Machine

View ProductsAuto PCB Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Can be configured with high-performance CO2, optical fiber, green light and UV laser, and with adjustable power.

-

Easy to operate and can etch various patterns, characters, 2D codes, 1D codes and other contents.

-

Highly intelligent, high precision, strong system stability, true coaxial technology. Can conduct marking and reading immediately, and with faster efficiency.

-

-

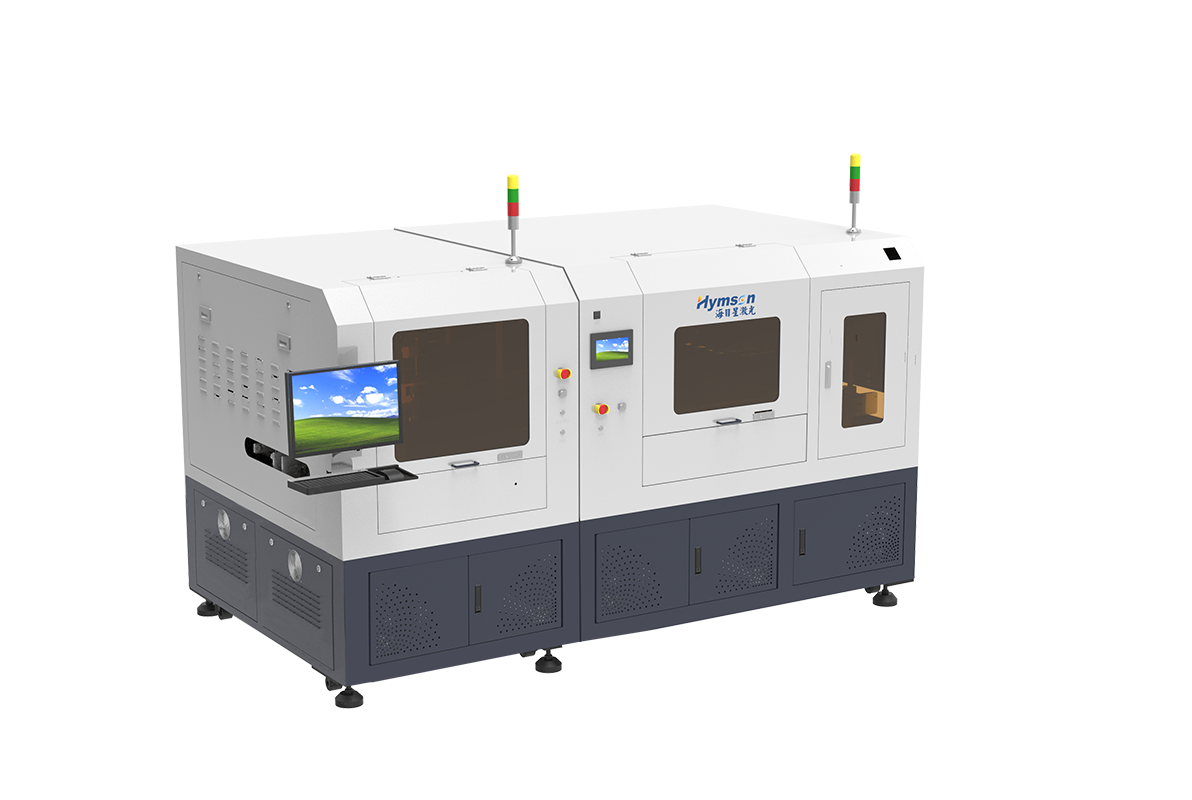

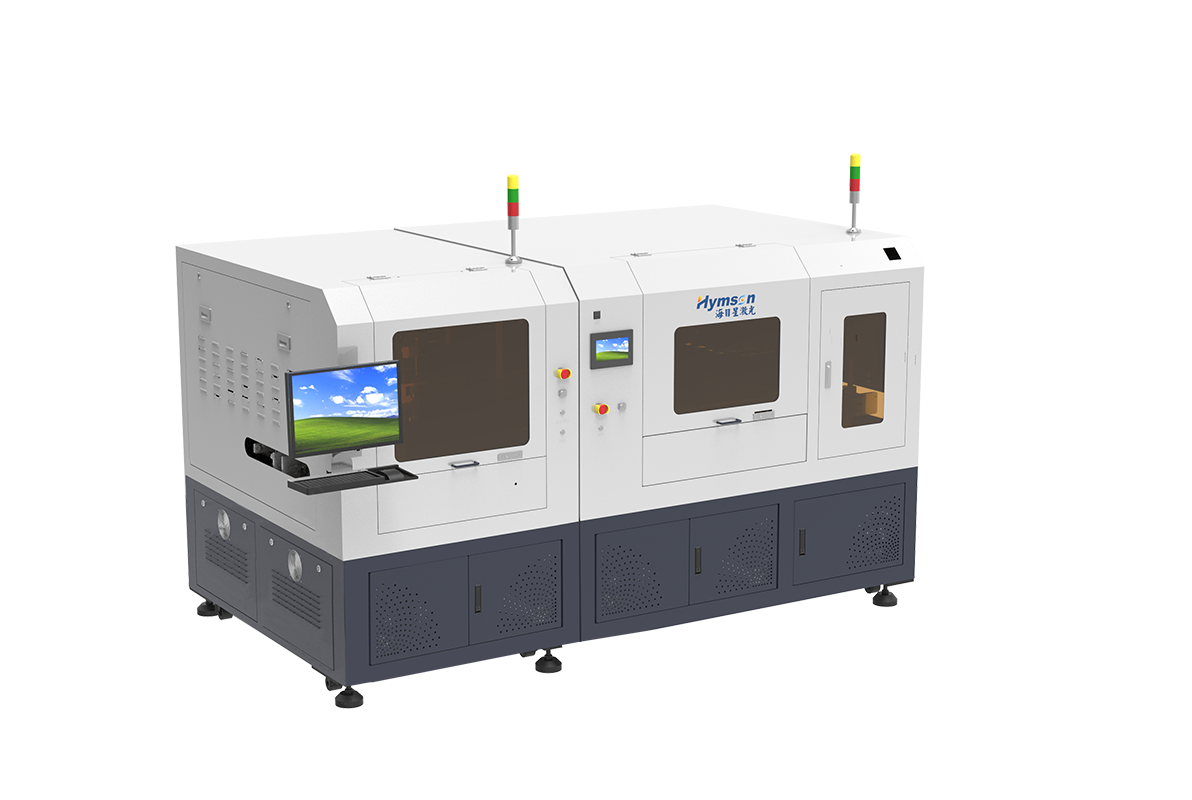

View ProductsDouble Station Laser Cutting Machine

View ProductsDouble Station Laser Cutting Machine-

Stress-free cutting avoids product damage caused by stress of material.

-

Dust free and environmental friendly.

-

The section of cutting surface is smooth and neat without burr and carbonization.

-

Applicable for the cutting of soft and hard bonding plates, with high precision for plate splitting.

-

-

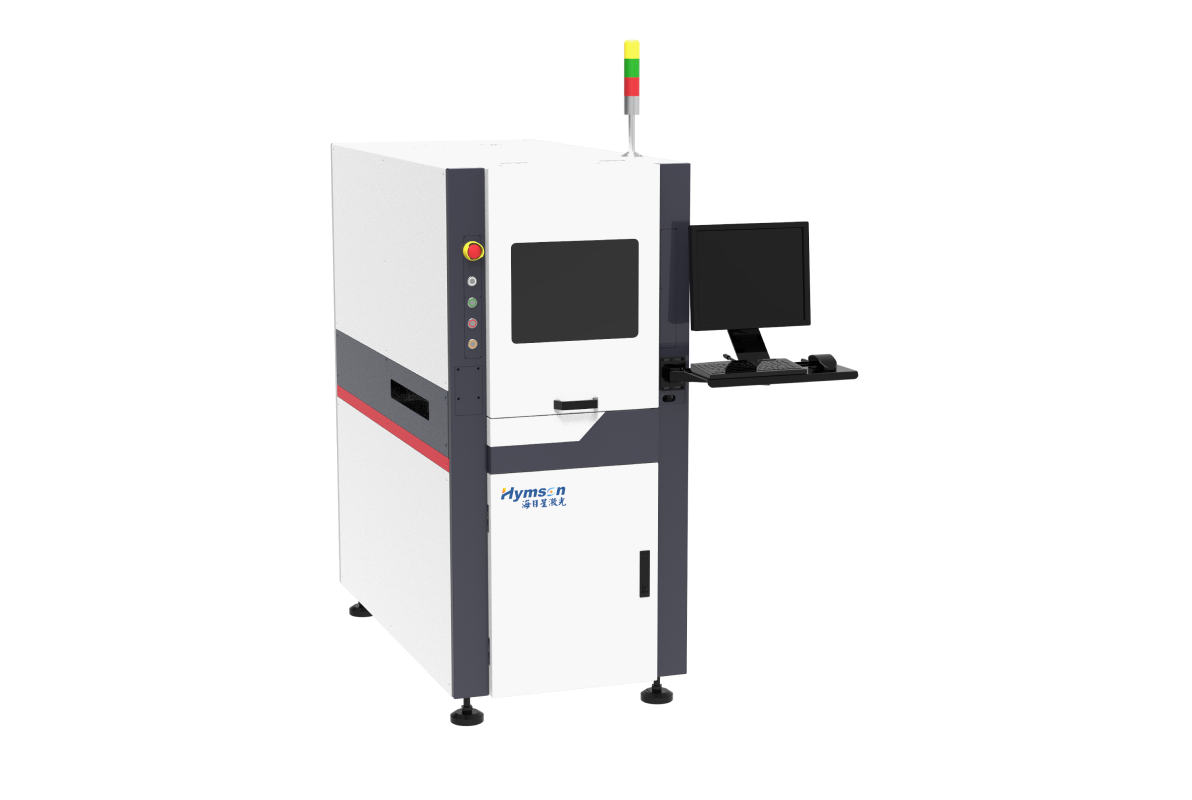

View ProductsPCB/FPC Online Laser Cutting Machine

View ProductsPCB/FPC Online Laser Cutting Machine-

No dust. Minor pollution to the environment

-

The cut surface section is smooth without burr and carbonization.

-

Non-stress cutting. Can avoid product damage caused by material stress.

-

Applicable to cutting soft and hard combination plates. The accuracy of plate splitting is high.

-

-

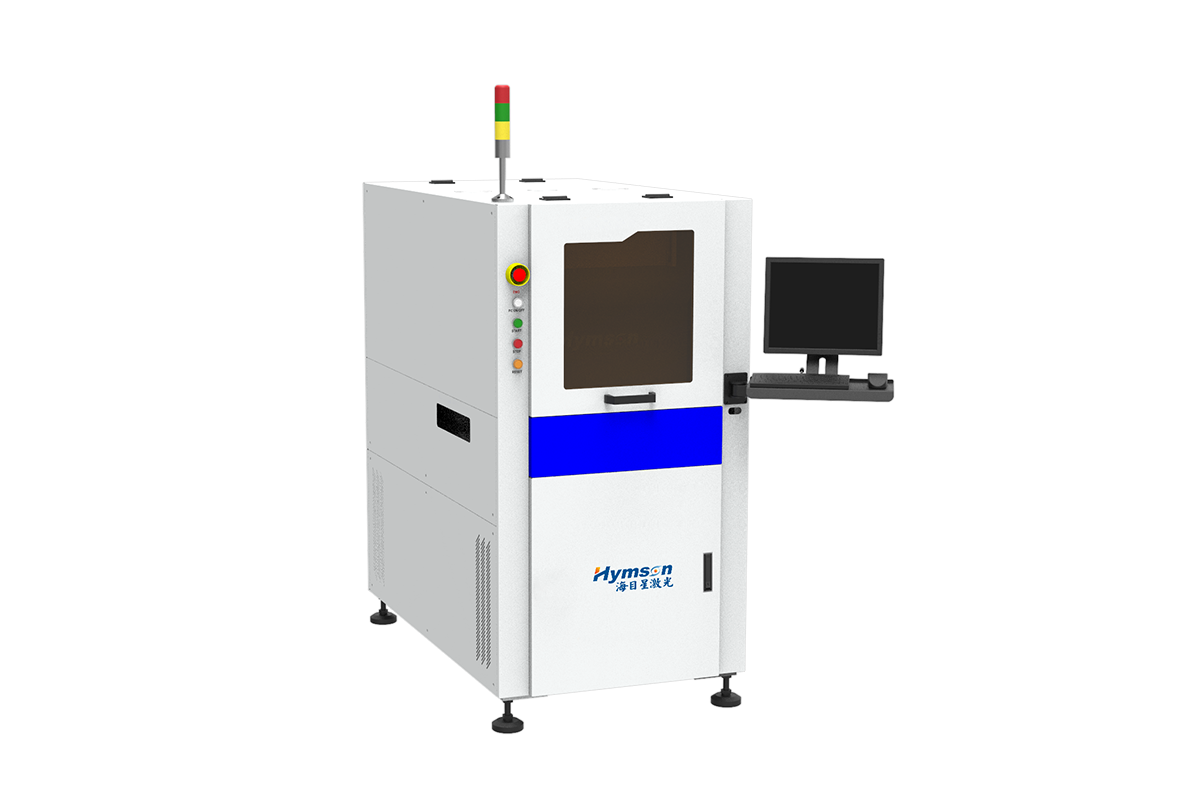

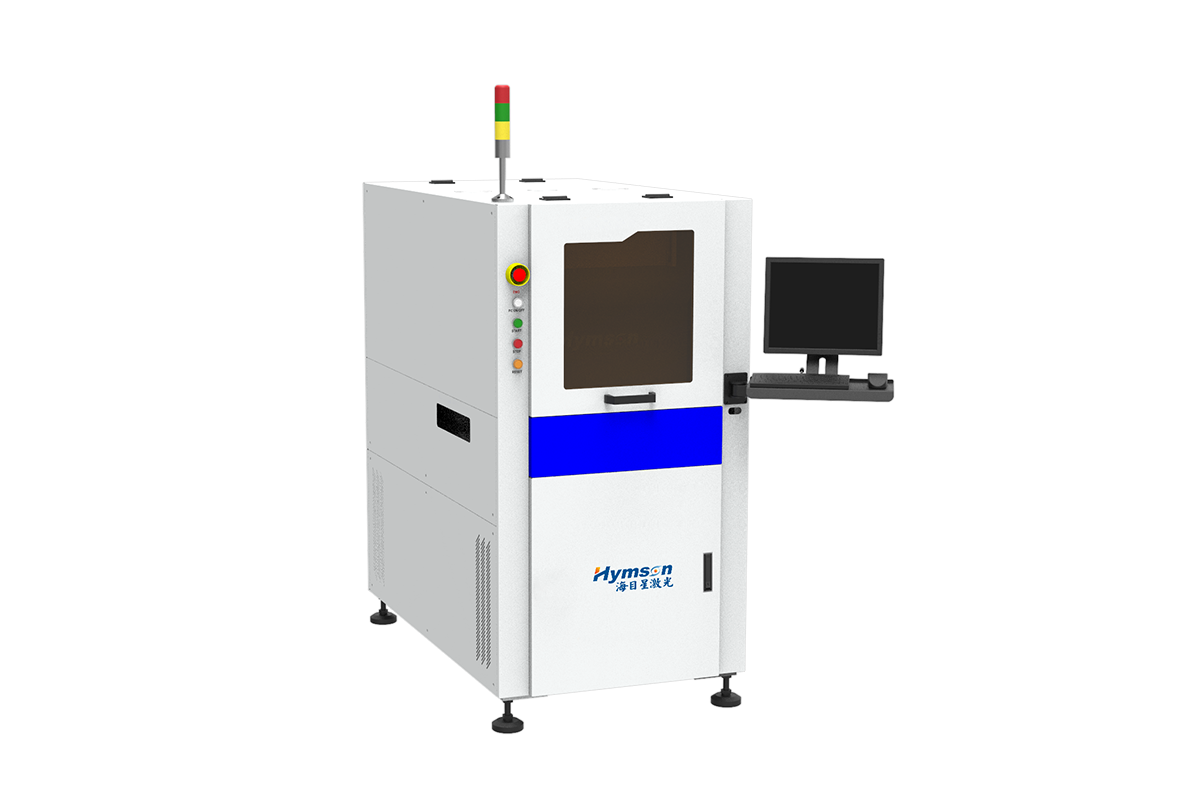

View ProductsAuto Laser Cutting Machine

View ProductsAuto Laser Cutting Machine-

No dust. Minor pollution to the environment

-

The cut surface section is smooth without burr and carbonization.

-

Non-stress cutting. Can avoid product damage caused by material stress.

-

Applicable to cutting soft and hard combination plates. The accuracy of plate splitting is high.

-

-

View ProductsPlastic Laser Welding Machine

View ProductsPlastic Laser Welding Machine-

Good sealing performance.

-

Weld strength equal to or greater than the base material.

-

Low power consumption, no noise, no consumables, no maintenance.

-

Laser, visual, temperature measurement three - in - one welding joint.

-

-

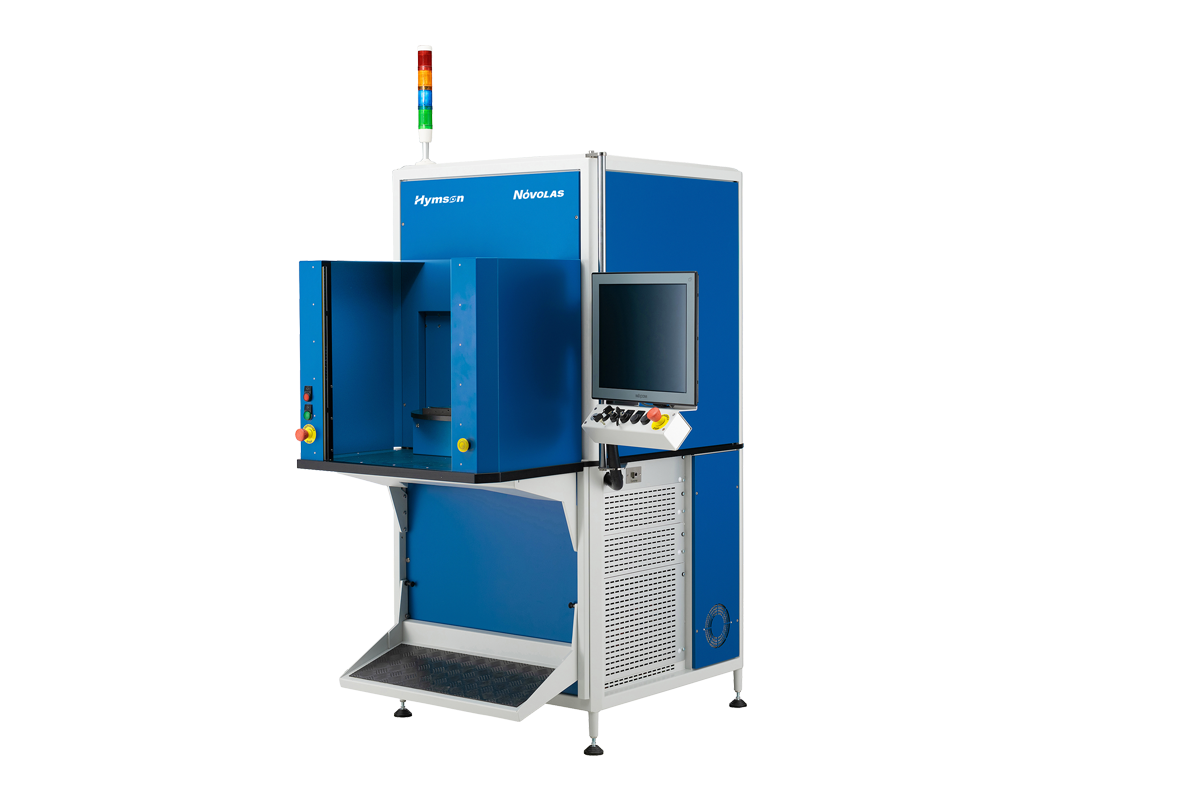

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

-

-

View ProductsAuto PCB Laser Marking Machine

View ProductsAuto PCB Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Can be configured with high-performance CO2, optical fiber, green light and UV laser, and with adjustable power.

-

Easy to operate and can etch various patterns, characters, 2D codes, 1D codes and other contents.

-

Highly intelligent, high precision, strong system stability, true coaxial technology. Can conduct marking and reading immediately, and with faster efficiency.

-

-

View ProductsDouble Station Laser Cutting Machine

View ProductsDouble Station Laser Cutting Machine-

Stress-free cutting avoids product damage caused by stress of material.

-

Dust free and environmental friendly.

-

The section of cutting surface is smooth and neat without burr and carbonization.

-

Applicable for the cutting of soft and hard bonding plates, with high precision for plate splitting.

-

-

View ProductsPCB/FPC Online Laser Cutting Machine

View ProductsPCB/FPC Online Laser Cutting Machine-

No dust. Minor pollution to the environment

-

The cut surface section is smooth without burr and carbonization.

-

Non-stress cutting. Can avoid product damage caused by material stress.

-

Applicable to cutting soft and hard combination plates. The accuracy of plate splitting is high.

-

-

View ProductsAuto Laser Cutting Machine

View ProductsAuto Laser Cutting Machine-

No dust. Minor pollution to the environment

-

The cut surface section is smooth without burr and carbonization.

-

Non-stress cutting. Can avoid product damage caused by material stress.

-

Applicable to cutting soft and hard combination plates. The accuracy of plate splitting is high.

-

-

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

View ProductsNOVOLAS Basic S

View ProductsNOVOLAS Basic S-

Flexible, modular laser system for integration.

-

Flexible, inexpensive, suited for a variety of applications.

-

High throughput.

-

Modular construction with diverse optional components.

-

-

-

-

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

View ProductsNOVOLAS Basic S

View ProductsNOVOLAS Basic S-

Flexible, modular laser system for integration.

-

Flexible, inexpensive, suited for a variety of applications.

-

High throughput.

-

Modular construction with diverse optional components.

-

-

View ProductsNOVOLAS Inline Welder

View ProductsNOVOLAS Inline Welder-

Laser-safe integration system.

-

Configurable with various lasers.

-

Space-optimized design with decentralized units.

-

Easily mountable on rotary indexing tables or conveyor belts.

-

-

View ProductsNOVOLAS TTS

View ProductsNOVOLAS TTS-

Compact and efficient table top laser welding device.

-

Cost-effective, air-cooled diode laser.

-

Multiple adjustable application modes.

-

Can be operated via HMI software.

-

-

View ProductsNOVOLAS WS-AT RTT

View ProductsNOVOLAS WS-AT RTT-

Turnkey laser system for all laser welding concepts.

-

Intuitive user interface.

-

Several laser and optical system modules per system.

-

Integrated online process control.

-

-

View ProductsNOVOLAS WS-AT

View ProductsNOVOLAS WS-AT-

Modular laser welding system for plastics.

-

User-friendly software.

-

Online process monitoring.

-

Easily integrates into existing processes.

-

-

Partner

Hymson dedicated to optimize production efficiency and energy utilization with high efficiency and stablization manufacturing equipment for partner