-

Hymson Laser

-

Solutions

-

EV Battery

Solutions

As electric vehicle becomes a global trend, battery enterprises are facing dual challenges in international competition, which primarily stem from high-quality manufacturing under mass production and new process development based on new materials and battery technologies. We create long-term value for battery production and accelerate its manufacture with our high-quality, automated and intelligent equipment, improving performance, conformity, safety, and recurrent durability.

- Coating & Calendering & Slitting Manufacturing

- High-Speed Laser Notching Intelligent Manufacturing

- High Speed Laser Ablation

- High Speed Winding

- Intelligent Solutions for Assembly Line

- Solutions for the Top-Cover Assembly of the Battery

- Auto Battery Baking Solutions

- EV Battery Module/Pack

- Laser Plastic Welding

-

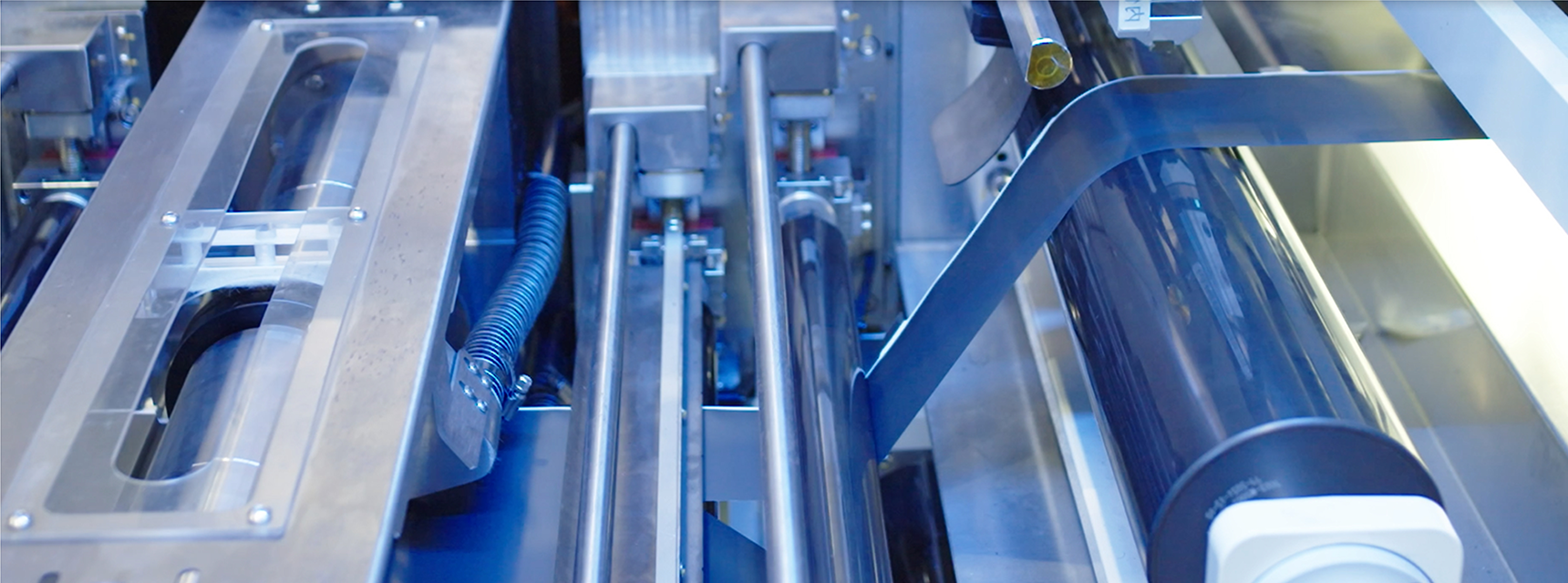

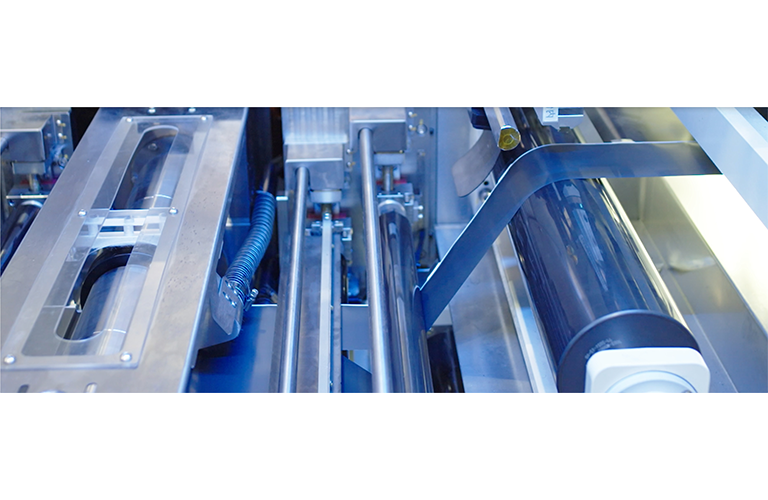

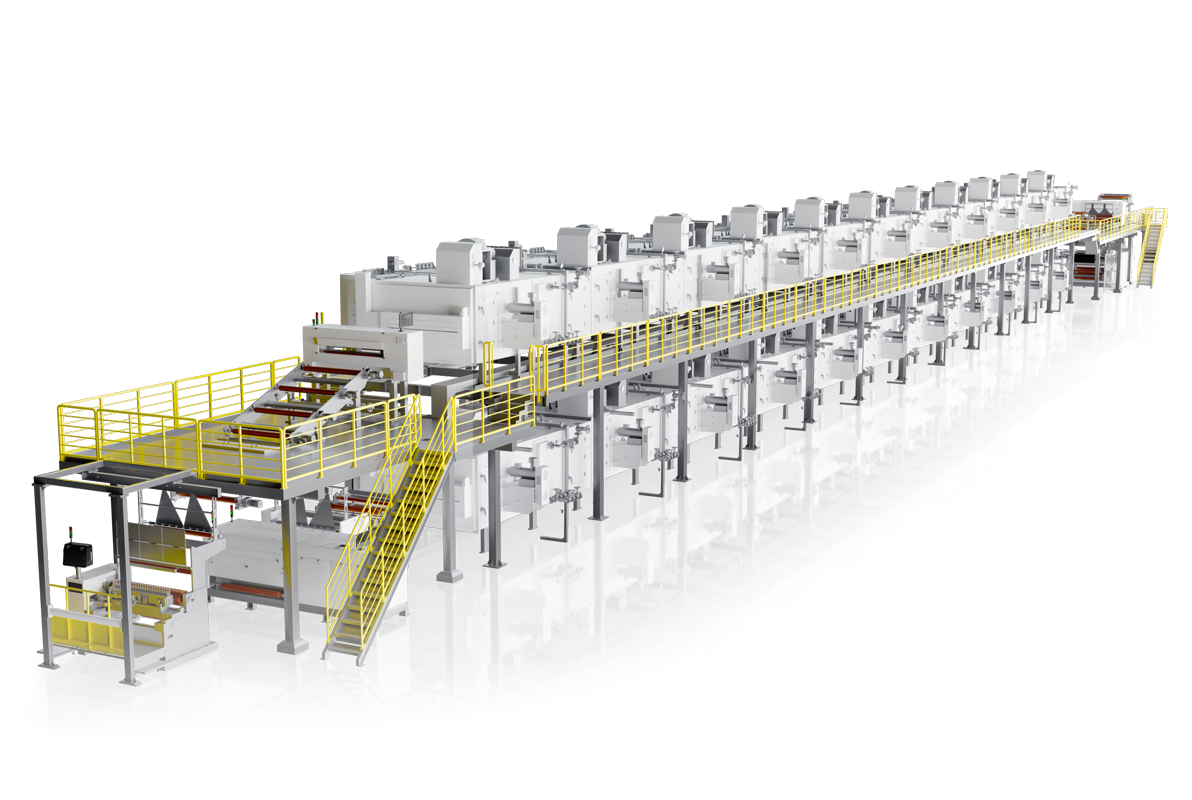

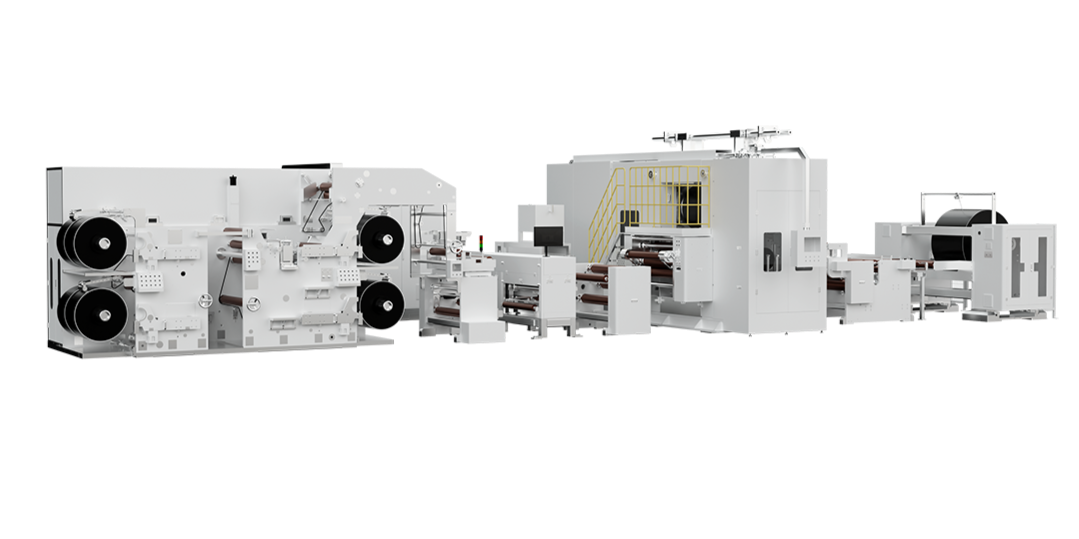

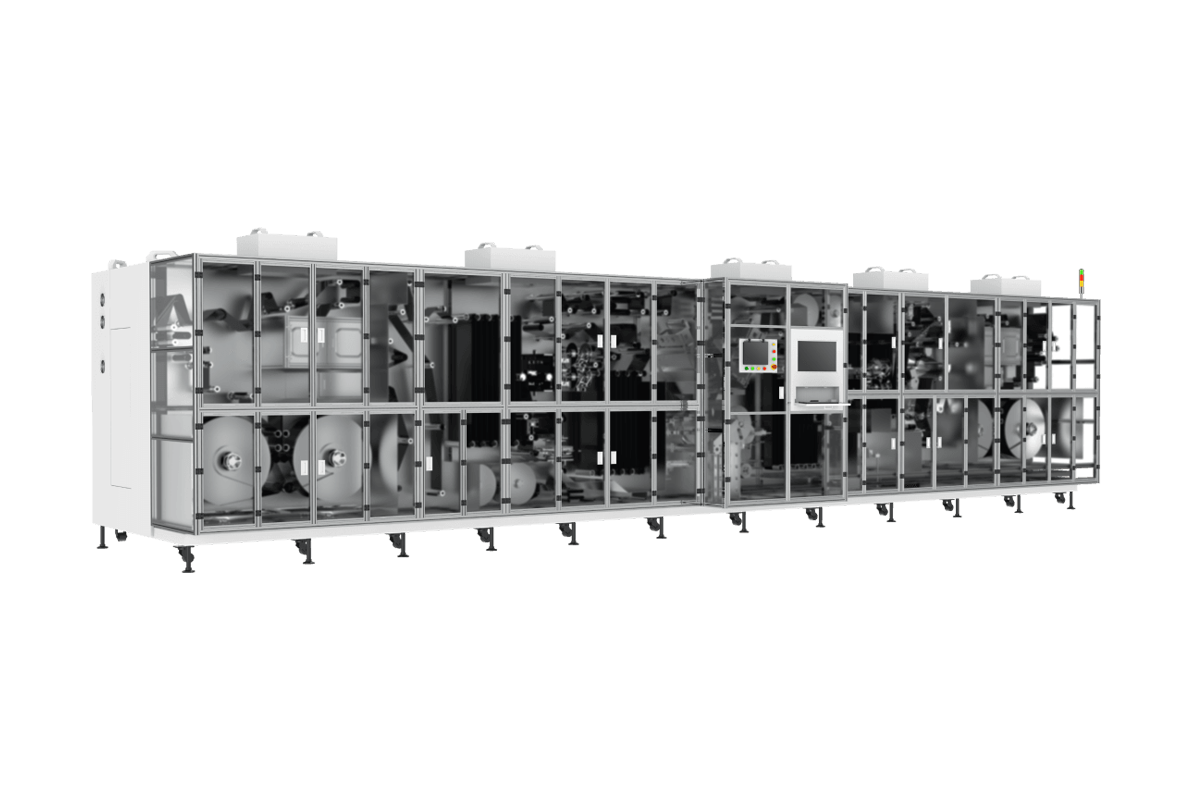

Coating & Calendering & Slitting Manufacturing Solutions

Pre-stage LIB manufacturing involves coating, calendering, and slitting processes that are crucial for the battery's energy density and safety. The integrated equipment incorporates multiple innovative technologies to efficiently address shaking, crinkling, and other industrial challenges, providing our clients with highly efficient, reliable pre-stage equipment that is convenient to maintain.

Get the solution-

High efficiencyProvide clients with high-quality, reliable and easy-to-maintain products as well as customized products with a high level of stability.

-

High yield, high reliabilityMultiple innovative technologies are being applied, including a single deck suspension drying oven, a coating machine based on an arc-shaped layout and gas-wing nozzles, to eliminate the shaking and crinkling of the foil and solve other industrial pain points.

-

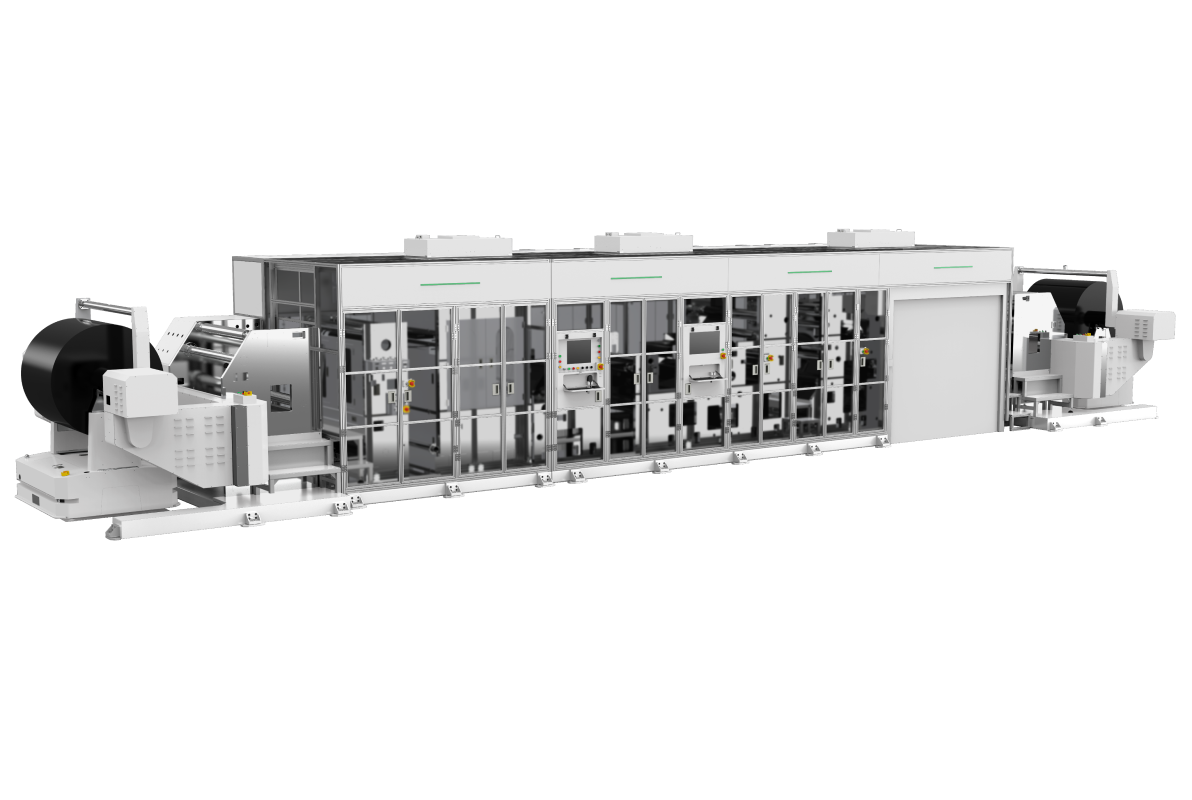

High-Speed Laser Notching Intelligent Manufacturing Solutions

Hymson has exceeded laser-notching technology limits by optimizing the charging and discharging of batteries, solving post-cutting burrs and coating detachment issues, and contributing to the improvement of battery performance and production efficiency.

Get the solution-

Mature cutting processSolve burrs, foil exposure, coating detachment, dedusting and other issues during electrode cutting

-

Support tab notching of various shapes and widthIntegrate tab notching, V-angle cutting and cross cutting; compatible with electrode of various width (150-1200mm)

-

Prime cutting qualityFeatured by stable process, excellent cutting conformity and high production efficiency

-

Integrated design to lower the costHighly integrated in process design to reduce processing costs

-

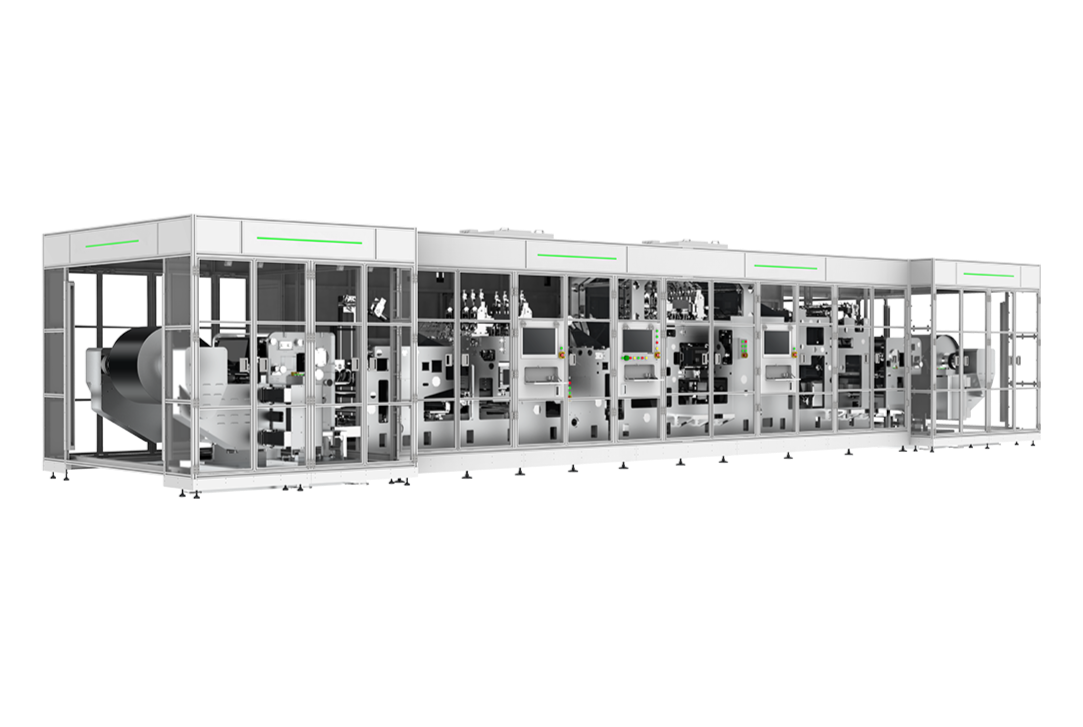

High Speed Laser Ablation Solution

Hymson has developed high speed laser ablation technologies to effectively resolve the defects of traditional cleaning machines, which include model change problems, low accuracy, contaminated materials, unsatisfactory cleaning performance, high maintenance costs, etc. It has been widely applied to the cleaning of electrode tabs, and it has greatly improved the full-line intelligent battery manufacturing process as a result of its high efficiency, environmental friendliness, excellent cleaning effects, and minimum damage to copper foil.

Get the solution-

Ablation of negative electrode coated area

Ablation of negative electrode coated area -

Ablation of positive electrode coated area

Ablation of positive electrode coated area

-

Prime cleaning qualityOptimization of key process parameters, including the power, frequency, and pulse-width of laser ablation, to improve the ablation effect. Residues<0.1 mm; pinholes<0.25 mm.

-

High ablation accuracyExclusive laser software allows highly accurate control of the ablation slot, ensuring a ablation difference between 0.20 mm and 0.30 mm with consistent cleaning result.

-

Customized ablation for multi-tabsCompatible width: 35-710 mm; Various pattern, customized cleaning for multi-tabs

-

-

High Speed Winding Solution

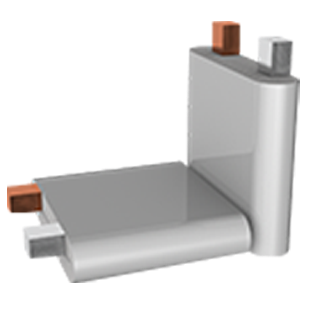

Adapt to winding process for prismatic and cylindrical battery. Integrated design of tab notching and cell winding reduces multiple costs for clients

Get the solution-

Prismatic Winding Cell

Prismatic Winding Cell

-

Dynamic Synchronizing between winding and notching unitsOptimal algorithm is adopted to realize the dynamic synchronizing between winding and notching and to ensure a stable mass production

-

Highly accurate control of chase-cutting and slittingPatented design of cutter structure with precise algorithm of chase-cutting keeps the cutting difference between ±0.3 mm

-

Constant linear velocity controlConstant linear speed for winding process with adjustable winding needle for various diameters, ensuring minimum fluctuation and realizing automatic alignment of tabs

-

-

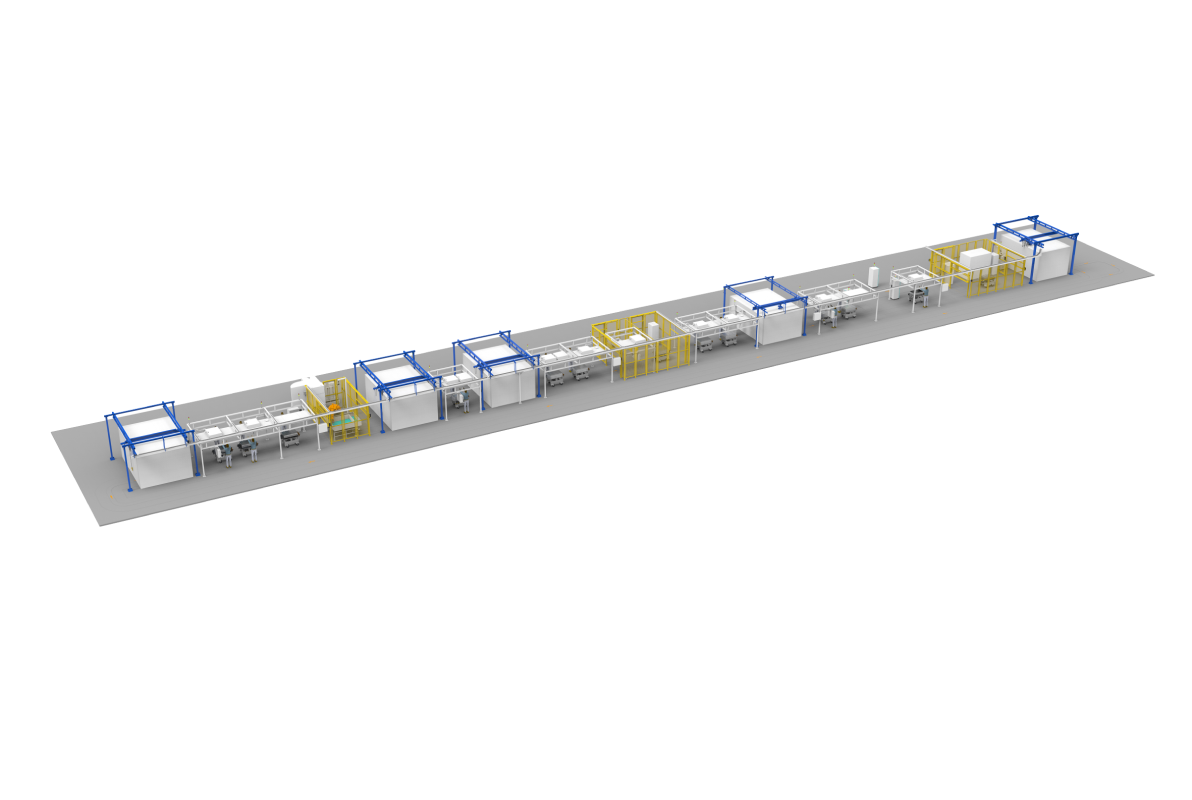

Intelligent Solutions for Assembly Line

Hymson will gradually realize the advanced manufacturing transition from 12 PPM to 20 PPM, to 22 PPM and to even higher capacity.

Get the solution-

Prismatic Battery

Prismatic Battery -

Blade Battery

Blade Battery

-

Highly accurate laser control technologyResponse time<5 us; Motion accuracy<5 μm; Frequency>10M Hz

-

Highly accurate fixture designRealize high speed and highly accurate assembly during the changing and positioning of the fixture

-

Robot visual technologyHigh speed inspection CT≤10 ms; Accuracy≤0.02 mm; Yield≥99.5%

-

Digital twin 3D visualization technologyImprove the user experience by the visualization of equipment status and the intelligent interaction of information.

-

-

Solutions for the Top-Cover Assembly of the Battery

Improve the top-cover stability and yield of the EV battery and energy storage battery.

Get the solution-

Prismatic Battery Top Cover

Prismatic Battery Top Cover

-

Excellent welding performanceReduce sparks; Excellent welding effect; High stability

WDD real time monitoring of energy fluctuation during welding -

High UPH30PPM

-

High compatibilityWidth: 20~85 mm; Length: 170~300 mm

-

Easy for MaintenanceSmall floor space allows shorter time for mode changing

-

-

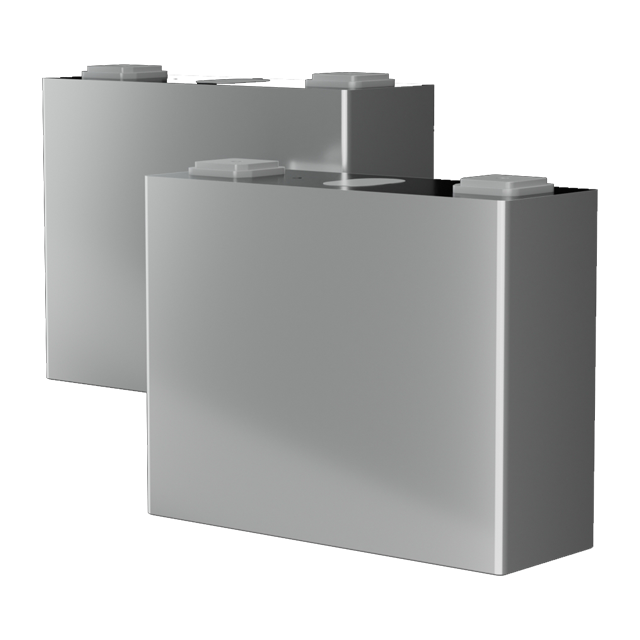

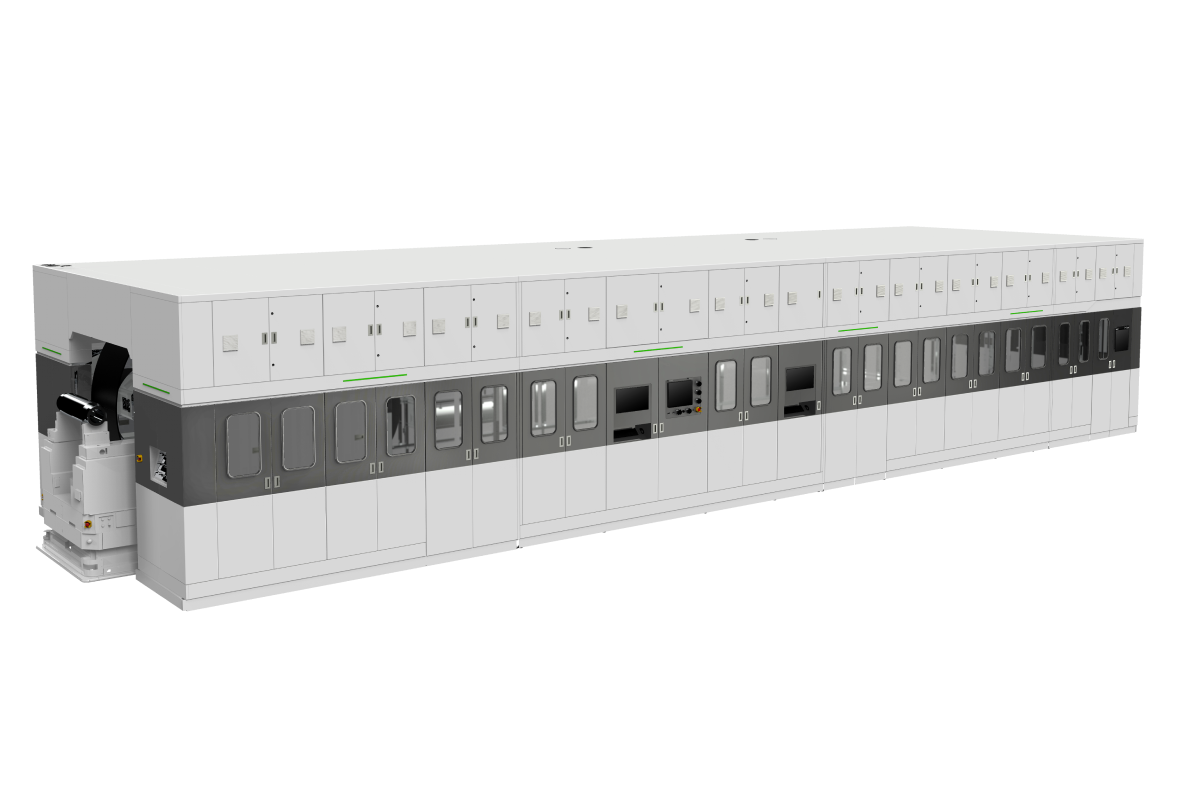

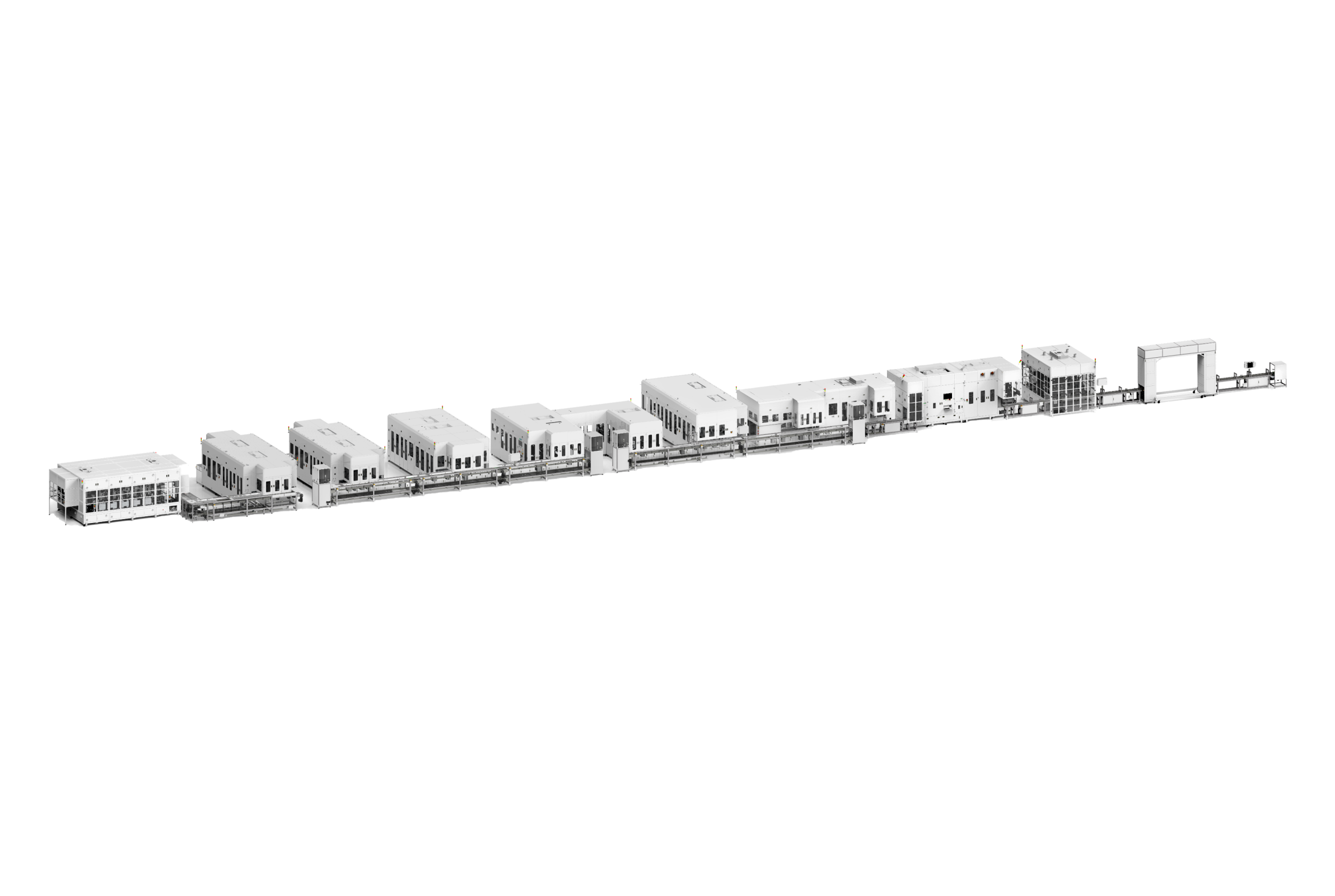

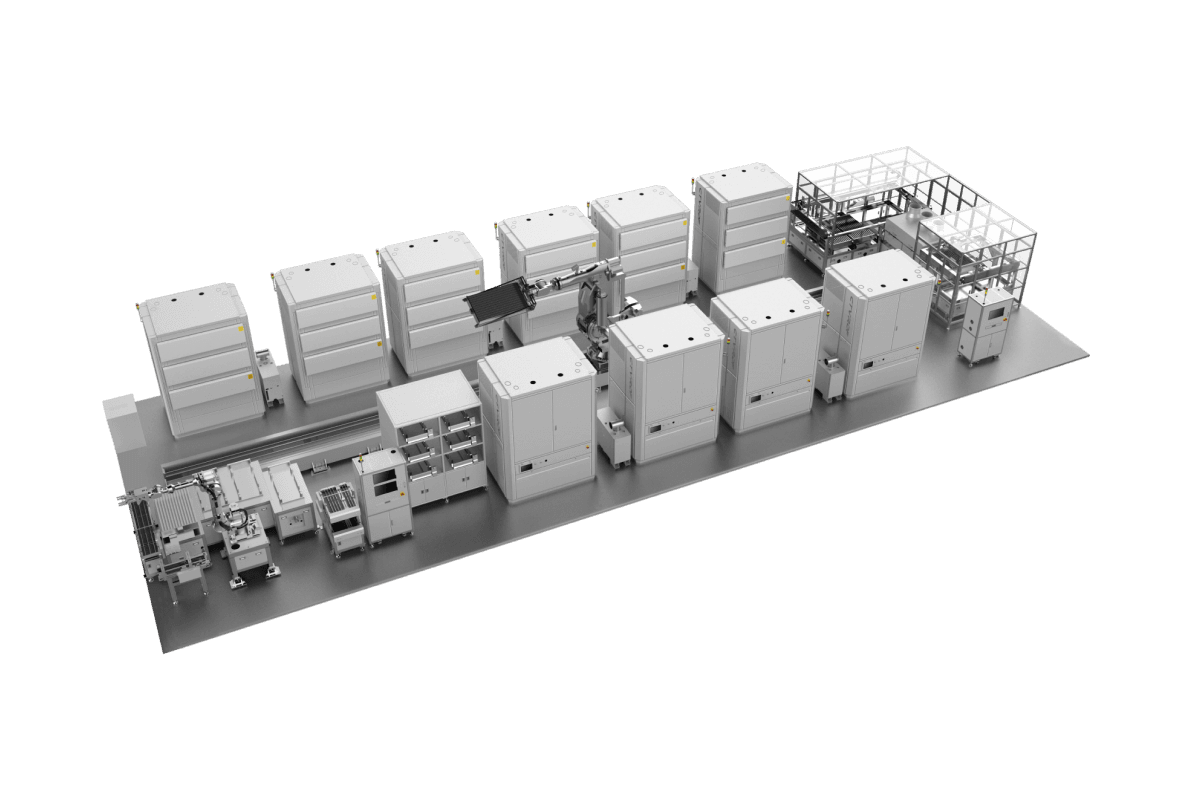

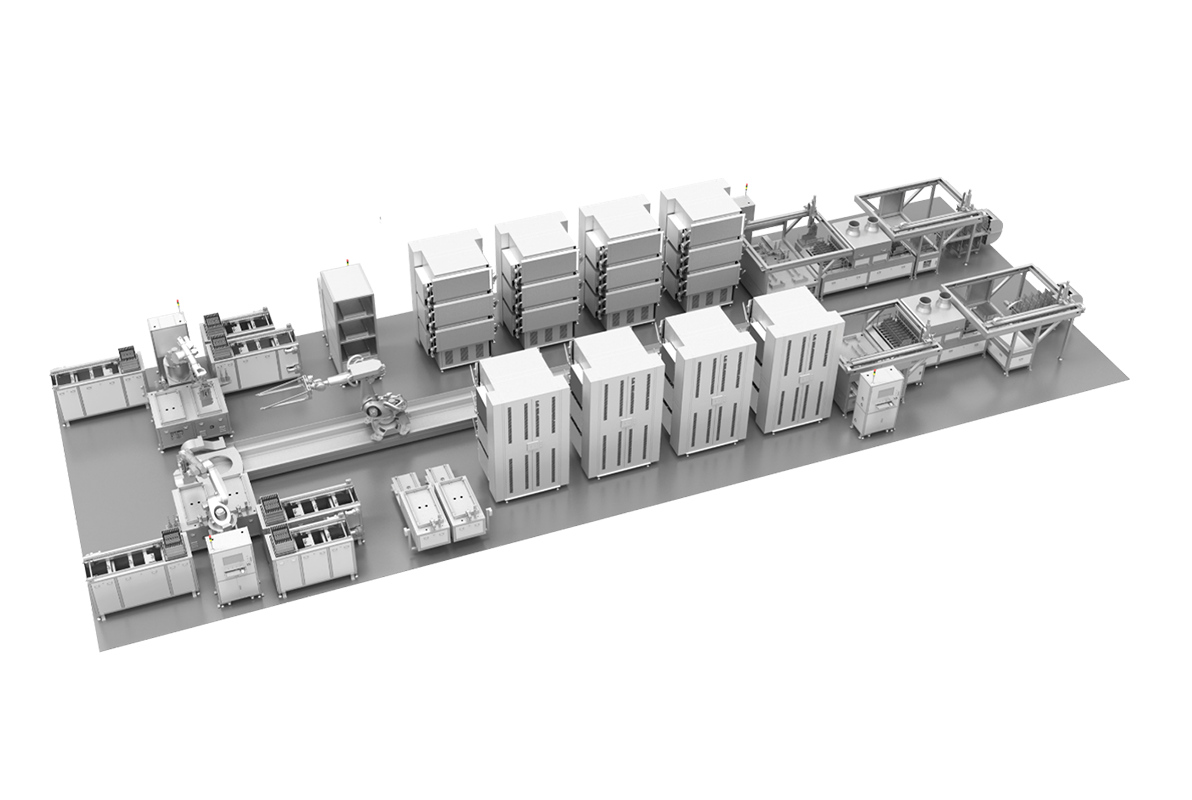

Auto Battery Baking Solutions

The equipment is used for the baking process of batteries (pouch, prismatic & cylindrical), which enables automatic production of battery loading, baking, cooling and unloading. With its flexible design, the entire solution can be easily changed, and with its integrated intelligent control system, the system performs real-time monitoring of the operation status of each module, ensuring the stability and safety of operations. In addition, a range of safety measures are implemented to ensure the safety of personnel and equipment.

Get the solution-

Prismatic Battery

Prismatic Battery

-

High AutomationRobots carrying & loading to improve efficiency

-

High EfficiencyThe application of robot grippers, automatic scheduling systems, logistics simulations, and other key technologies improves the efficiency of the entire production line. Using contact heat can ensure close distance between the battery and the heating plate, thus reduce heat loss and improve baking efficiency. The original internal circulation air cooling provides fast and efficient cooling.

-

High FlexibilityModular design of the equipment allows it to be rearranged according to the plant layout on-site. In addition, each module can operate independently without interfering with the others so as to increase the production capacity.

-

-

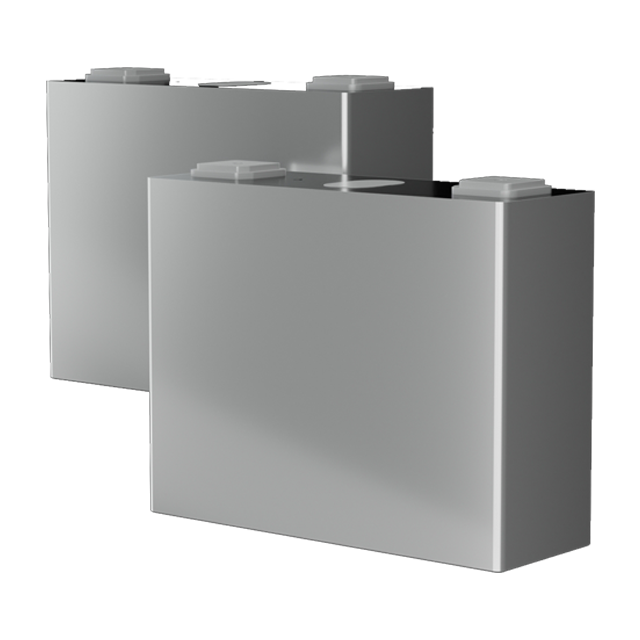

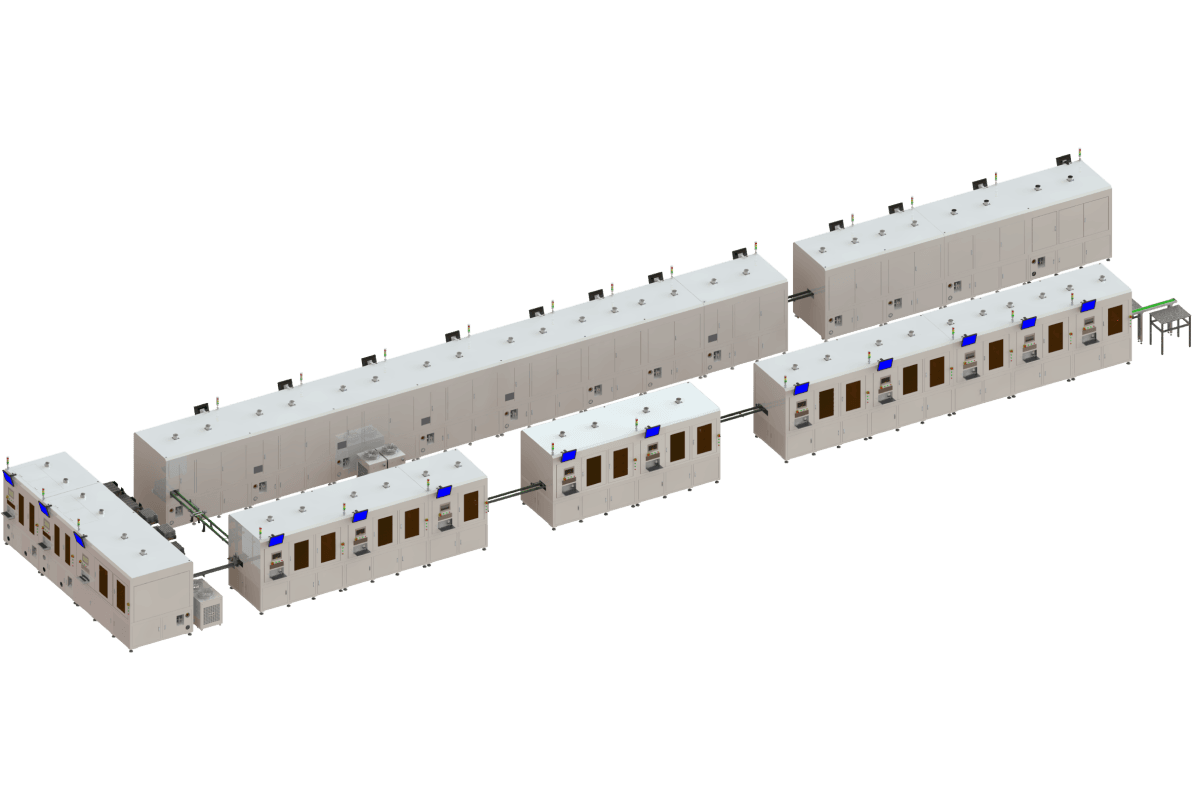

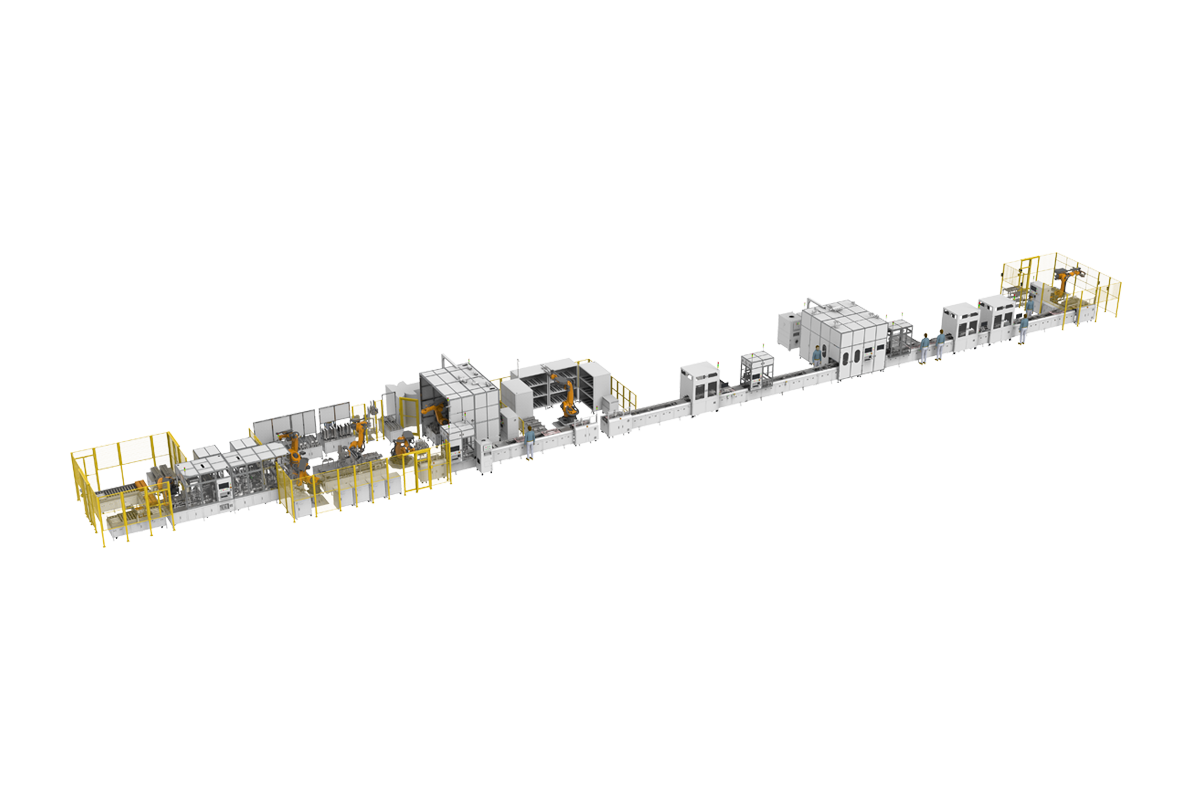

EV Battery Module/Pack Solutions

With the core technologies of units modularization, robot control, welding control and quality inspection, visual inspection, intelligent dynamic compensation, multi-axis motion control and AGV scheduling, Hymson has created a intelligent manufacturing solution for EV battery module/PACK, which has overcome the problems of imperfect industrial production automation, poor detection capability, weak battery consistency and stability, and significantly improved the production efficiency and product quality of battery modules/pack (PACK).

Get the solution-

EV Battery Module Pack

EV Battery Module Pack

-

High AutomationApplication of new technologies such as robotics, lasers, visual recognition, automatic tightening, and leakage testing can improve the efficiency and productivity of production lines.

-

High EfficiencyUsing virtual commissioning to improve production efficiency, reduce on-site commissioning costs, and shorten on-site commissioning cycles. AI welding system is used to visualize, monitor, and control quality in the design, processing, inspection, and motion phases.

-

High FlexibilityModular and flexible design can meet the compatibility and production rate of production line

-

Highly Accurate Simulation TechnologyCreate a large arithmetic center, using 3D simulation technology to simulate assembly processes, ergonomics, and robot operations; using simulation technology to test equipment, speed up equipment application, shorten R&D cycles, and achieve rapid and stable output over time.

-

-

Laser Plastic Welding

Suitable for components such as cell insulation films, battery housings, and cooling system piping, achieving high-precision welding to ensure battery safety and longevity.

Get the solution-

Insulation film

Insulation film -

Plastic Battery Housing

Plastic Battery Housing -

Explosion-Proof Valve

Explosion-Proof Valve

-

Precision EncapsulationNon-contact welding to prevent damage to the internal structure of the cell, ensuring consistent battery performance.

-

Efficient ProductionSupports multi-laser synchronous processing, significantly reducing cycle times and enhancing production line efficiency.

-

Clean & Contamination-FreeThe welding process does not damage electronic components, meeting the cleanliness requirements of battery production clean rooms.

-

Main Products

A solution based on advance technologies and mature application experiences, which covers the complete stages of lithium battery manufacturing.

-

Coating & Calendering & Slitting Manufacturing

-

High-Speed Laser Notching Intelligent Manufacturing

-

High Speed Laser Ablation

-

High Speed Winding

-

Intelligent Solutions for Assembly Line

-

Solutions for the Top-Cover Assembly of the Battery

-

Auto Battery Baking Solutions

-

EV Battery Module/Pack

-

Laser Plastic Welding

-

-

View ProductsHigh-Speed Coating Machine (Double-Deck & Multi-Lane )

View ProductsHigh-Speed Coating Machine (Double-Deck & Multi-Lane )-

Auto unwinding and rewinding (turret).

-

Repeated positioning accuracy of module head: 1µm.

-

Double- deck drying oven in an arc-shaped layout enables a smooth electrode running.

-

High flexibility enabled by driven guide rollers with thin oil.

-

-

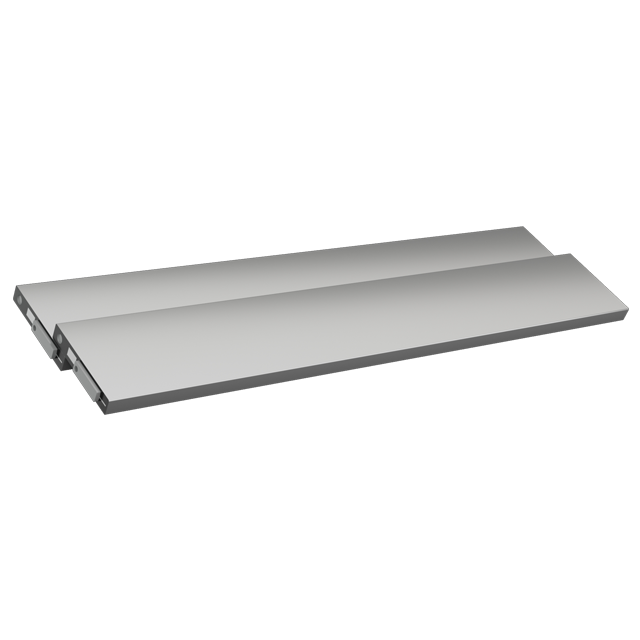

View ProductsCalendering & Slitting Integrated Machine

View ProductsCalendering & Slitting Integrated Machine-

Dual-position rewinding with sliding air shaft

-

Wrinkle removal by stretching unit

-

Calibrate the rollers by stretching bending cylinder

-

Adjust roller distance by mechanical operation and servo cylinder

-

-

-

-

View ProductsHigh-Speed S-Shape Laser Notching Machine

View ProductsHigh-Speed S-Shape Laser Notching Machine-

Large plate supporting structure on both sides.

-

Integrated functions of pre-slitting, tab notching and slitting; small floor space.

-

S-shape tab-notching and shared use of foil to save material costs.

-

High efficiency in dust removal with multiple dust removal systems.

-

-

View ProductsHigh-Speed Laser Notching & Cross-cutting Integrated Machine

View ProductsHigh-Speed Laser Notching & Cross-cutting Integrated Machine-

Suitable for stacking process.

-

The equipment adopts large plate supporting structure on one side.

-

Magazine is applied to receive materials and is transferred by logistic line.

-

High processing efficiency with consistent cutting quality.

-

-

View ProductsHigh-Speed Laser Notching & Slitting Integrated Machine (Horizontal)

View ProductsHigh-Speed Laser Notching & Slitting Integrated Machine (Horizontal)-

Large plate supporting structure on both sides.

-

High processing efficiency with consistent cutting quality.

-

Highly accurate feeding unit.

-

High speed laser dynamic controlling system.

-

-

View ProductsHigh-Speed Laser Notching & Slitting Integrated Machine (Vertical)

View ProductsHigh-Speed Laser Notching & Slitting Integrated Machine (Vertical)-

Cantilever supporting structure with large board on single side.

-

High processing efficiency with consistent cutting quality.

-

Highly accurate feeding unit.

-

High speed laser dynamic controlling system.

-

-

View ProductsHigh-speed laser notching machine

View ProductsHigh-speed laser notching machine-

Cantilever supporting structure with large plate on single side.

-

High processing efficiency with consistent cutting quality.

-

Highly accurate feeding unit.

-

High speed laser dynamic controlling system.

-

-

-

-

View ProductsMulti-Lane Laser Ablation Machine

View ProductsMulti-Lane Laser Ablation Machine-

Large plate supporting structure on both sides.

-

Highly accurate feeding unit.

-

High-precision OCTO laser position adjustment system.

-

High tension control accuracy enabled by multi-section electrode buffering system and tension control system; Compatible with A-A, A-B, B-B side ablation.

-

-

View ProductsSingle-Lane Laser Ablation Machine

View ProductsSingle-Lane Laser Ablation Machine-

Cantilever supporting structure with large plate on single side.

-

Highly accurate feeding unit.

-

Time-sharing laser ablation system.

-

High tension control accuracy enabled by multi-section electrode buffering system and tension control system.

-

-

-

-

View ProductsHigh-Speed Prismatic Cell Winding Machine

View ProductsHigh-Speed Prismatic Cell Winding Machine-

Automatic correction of tab alignment enabled by winding needle with variable diameters.

-

Four grades of electrode position correction, forming closed loop control with CCD.

-

High performance moving controller and advanced technology from Omron.

-

Track notching and cross-cutting for incoming electrode.

-

-

View ProductsCylindrical Notching & Winding Integrated Machine

View ProductsCylindrical Notching & Winding Integrated Machine-

Tab notching position control by correction unit and CCD closed loop inspection.

-

Multiple dust removal system with high efficiency.

-

Internal calculating and information tracing for NG rejection.

-

Online monitoring and dynamic adjustment of tab notching dimensions and tab winding alignment.

-

-

View ProductsPrismatic Cell Notching & Winding Integrated Machine

View ProductsPrismatic Cell Notching & Winding Integrated Machine-

Winding needle is directly driven by DD motor with speed fluctuation ≤0.2%.

-

Four grades of electrode position correction, forming closed loop control with CCD.

-

High performance moving controller and advanced technology from Omron.

-

Track notching and cross-cutting for incoming electrode.

-

-

-

-

View ProductsFull-Auto Prismatic Cell Assembly Line

View ProductsFull-Auto Prismatic Cell Assembly Line-

Highly automatic, complete the assembly processes without human intervention

-

Modular design, short changeover time, few parts, low costs

-

Automatic process control with traceable information for the whole processes, which can dock all types of MES systems

-

Digital twin 3D visualization technology, equipment state visualization, intelligent information interaction, improve user experience.

-

-

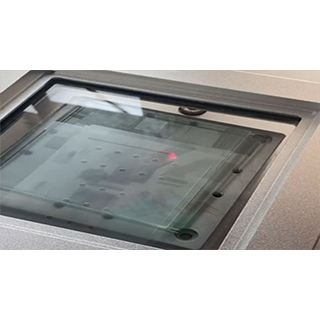

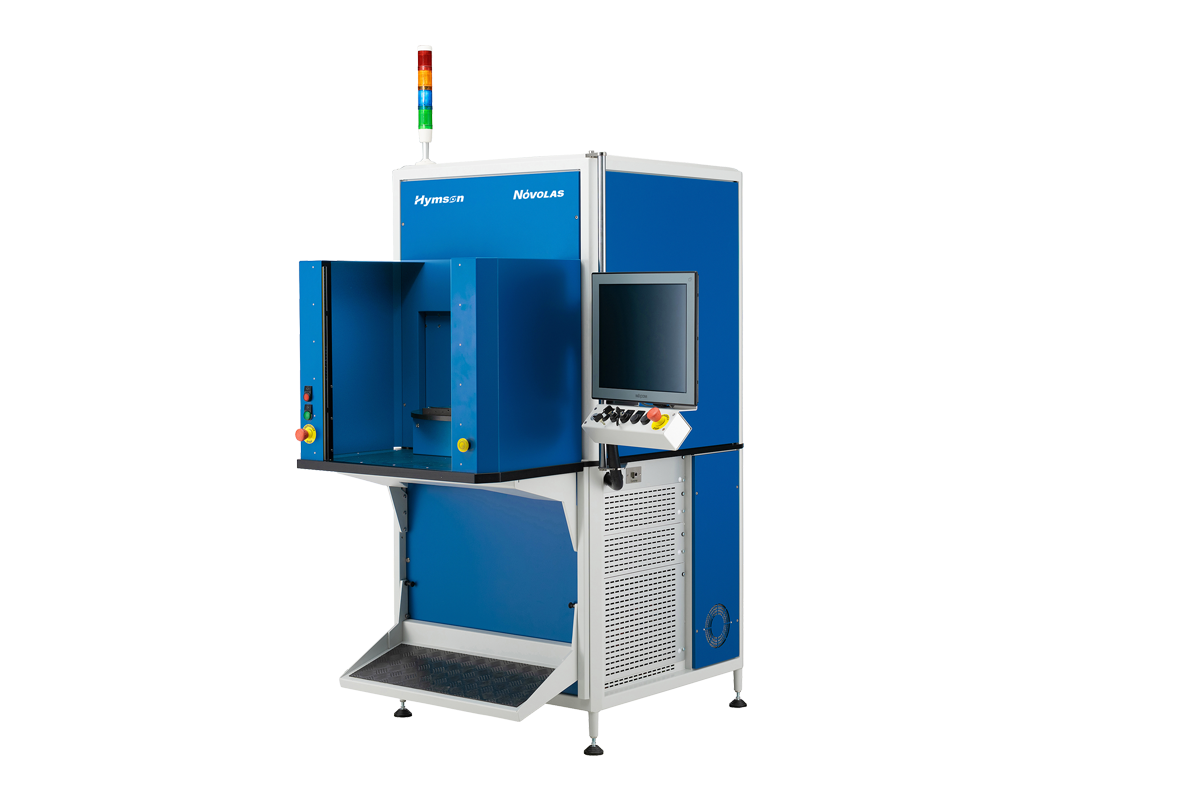

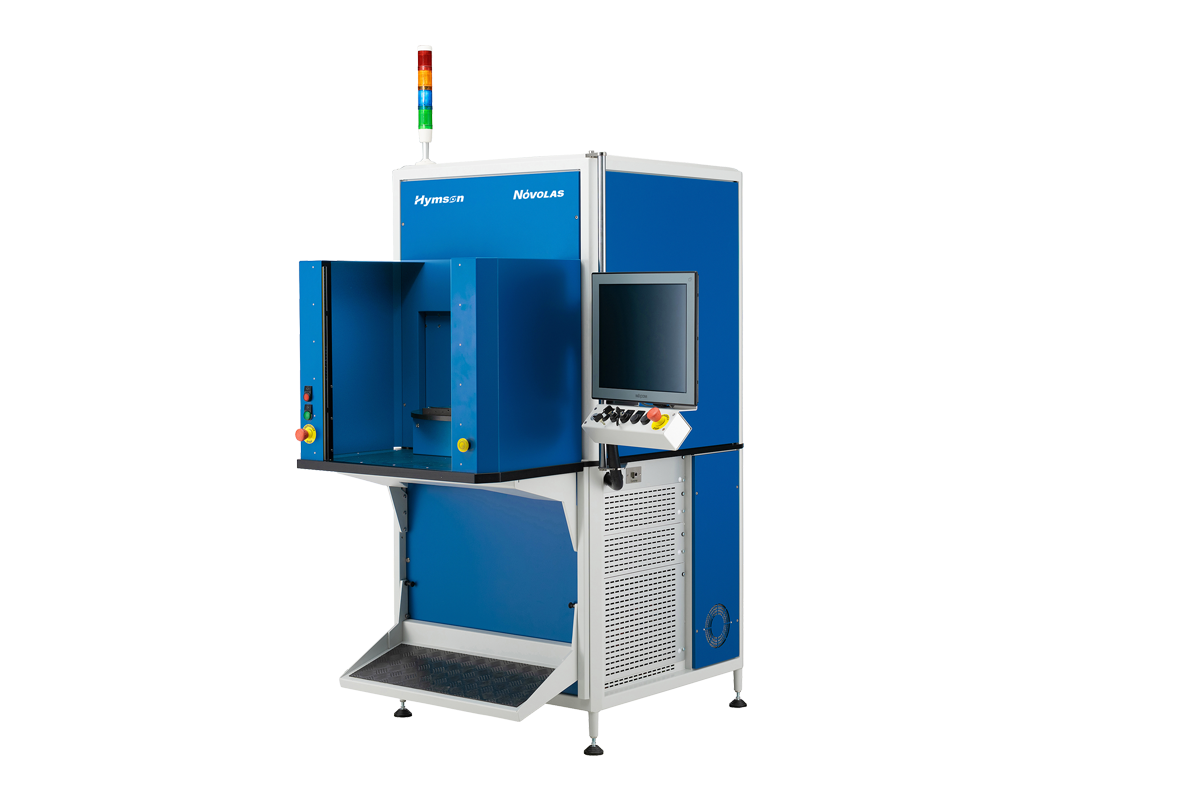

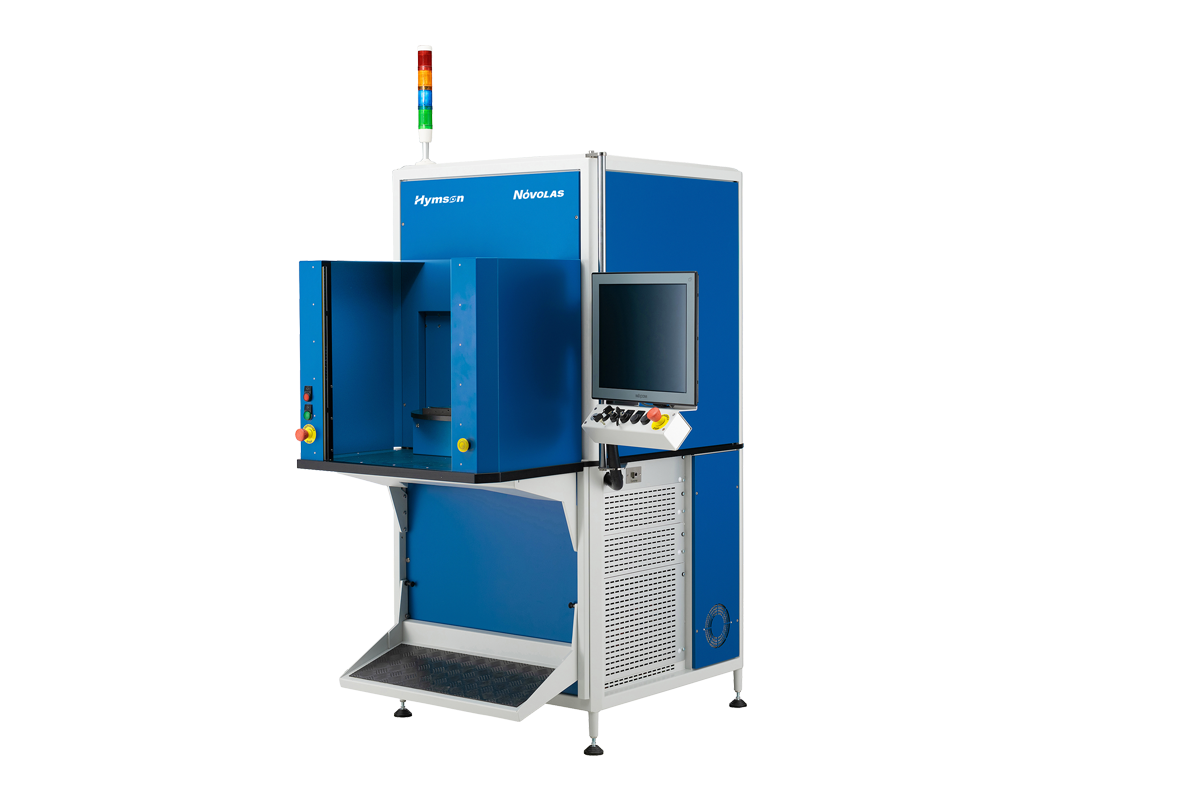

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

View ProductsNOVOLAS Basic S

View ProductsNOVOLAS Basic S-

Flexible, modular laser system for integration.

-

Flexible, inexpensive, suited for a variety of applications.

-

High throughput.

-

Modular construction with diverse optional components.

-

-

View ProductsNOVOLAS Inline Welder

View ProductsNOVOLAS Inline Welder-

Laser-safe integration system.

-

Configurable with various lasers.

-

Space-optimized design with decentralized units.

-

Easily mountable on rotary indexing tables or conveyor belts.

-

-

View ProductsNOVOLAS TTS

View ProductsNOVOLAS TTS-

Compact and efficient table top laser welding device.

-

Cost-effective, air-cooled diode laser.

-

Multiple adjustable application modes.

-

Can be operated via HMI software.

-

-

View ProductsNOVOLAS WS-AT RTT

View ProductsNOVOLAS WS-AT RTT-

Turnkey laser system for all laser welding concepts.

-

Intuitive user interface.

-

Several laser and optical system modules per system.

-

Integrated online process control.

-

-

-

-

View ProductsAuto Assembly Line of Top Cover

View ProductsAuto Assembly Line of Top Cover-

Systemized dust and particle prevention treatment.

-

Equipped with self-inspection and foolproof functions for incoming materials.

-

MES system full closed-loop production processing

-

Less spatter, good weld effect and high stability

-

-

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

View ProductsNOVOLAS Basic S

View ProductsNOVOLAS Basic S-

Flexible, modular laser system for integration.

-

Flexible, inexpensive, suited for a variety of applications.

-

High throughput.

-

Modular construction with diverse optional components.

-

-

View ProductsNOVOLAS Inline Welder

View ProductsNOVOLAS Inline Welder-

Laser-safe integration system.

-

Configurable with various lasers.

-

Space-optimized design with decentralized units.

-

Easily mountable on rotary indexing tables or conveyor belts.

-

-

View ProductsNOVOLAS TTS

View ProductsNOVOLAS TTS-

Compact and efficient table top laser welding device.

-

Cost-effective, air-cooled diode laser.

-

Multiple adjustable application modes.

-

Can be operated via HMI software.

-

-

View ProductsNOVOLAS WS-AT RTT

View ProductsNOVOLAS WS-AT RTT-

Turnkey laser system for all laser welding concepts.

-

Intuitive user interface.

-

Several laser and optical system modules per system.

-

Integrated online process control.

-

-

-

-

View ProductsFull-Auto Prismatic Cell Baking Line

View ProductsFull-Auto Prismatic Cell Baking Line-

Highly automatic, complete the assembly processes without human intervention

-

High compatibility, adapt to various series of products

-

Modular design, short changeover time, few parts, low costs

-

High assembly precision, dual positioning by visual and mechanical ways to improve positioning accuracy

-

-

View ProductsFull-Auto Pouch Cell Baking Line

View ProductsFull-Auto Pouch Cell Baking Line-

Robot carrying and lading to realize high stability

-

Low energy consumption, heat preservation under non-heating state

-

Small capacity of fixture cavity enables fast air extraction and low missing rate

-

Anti-bump design of the grippers, protecting the devices and product from damage

-

-

-

-

View ProductsModule Assembly Line

View ProductsModule Assembly Line-

Full test of the cell voltage, resistance and thickness to ensure assembly consistency

-

Cell dispensing by two-component nozzle fixed on truss with adjustable glue pressure and mixing ratio and flow monitoring function

-

Unified standards for cell stacking, with high stacking accuracy and one-button switching of stacking modes

-

Visual addressing and off-focus measuring before laser welding to avoid missing welding and incomplete welding, and guarantee welding quality

-

-

View ProductsPACK Assembly Line

View ProductsPACK Assembly Line-

Completing the transmission of packs between stations by latent traction AGV.

-

Each station can be controlled independently.

-

6-axis machine equipped with two-component gluing heads to glue the bottom cover with adjustable glue pressure and mixing ratio and flow monitoring function

-

MES, full closed loop control system

-

-

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

View ProductsNOVOLAS Basic S

View ProductsNOVOLAS Basic S-

Flexible, modular laser system for integration.

-

Flexible, inexpensive, suited for a variety of applications.

-

High throughput.

-

Modular construction with diverse optional components.

-

-

View ProductsNOVOLAS Inline Welder

View ProductsNOVOLAS Inline Welder-

Laser-safe integration system.

-

Configurable with various lasers.

-

Space-optimized design with decentralized units.

-

Easily mountable on rotary indexing tables or conveyor belts.

-

-

View ProductsNOVOLAS TTS

View ProductsNOVOLAS TTS-

Compact and efficient table top laser welding device.

-

Cost-effective, air-cooled diode laser.

-

Multiple adjustable application modes.

-

Can be operated via HMI software.

-

-

-

-

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

View ProductsNOVOLAS Basic S

View ProductsNOVOLAS Basic S-

Flexible, modular laser system for integration.

-

Flexible, inexpensive, suited for a variety of applications.

-

High throughput.

-

Modular construction with diverse optional components.

-

-

View ProductsNOVOLAS Inline Welder

View ProductsNOVOLAS Inline Welder-

Laser-safe integration system.

-

Configurable with various lasers.

-

Space-optimized design with decentralized units.

-

Easily mountable on rotary indexing tables or conveyor belts.

-

-

View ProductsNOVOLAS TTS

View ProductsNOVOLAS TTS-

Compact and efficient table top laser welding device.

-

Cost-effective, air-cooled diode laser.

-

Multiple adjustable application modes.

-

Can be operated via HMI software.

-

-

View ProductsNOVOLAS WS-AT RTT

View ProductsNOVOLAS WS-AT RTT-

Turnkey laser system for all laser welding concepts.

-

Intuitive user interface.

-

Several laser and optical system modules per system.

-

Integrated online process control.

-

-

View ProductsNOVOLAS WS-AT

View ProductsNOVOLAS WS-AT-

Modular laser welding system for plastics.

-

User-friendly software.

-

Online process monitoring.

-

Easily integrates into existing processes.

-

-

Partner

Hymson contributes to the highly efficient and stable development of its partners and to optimizing the material transformation efficiency and energy use.