-

Hymson Laser

-

Products

OVERVIEW

Product Description

Automatic IC Laser Marking Machine

Automatic IC laser marking Automatic IC laser marking machine is mainly used on chip surface, such as metal, ceramic, plastic packaging, epoxy resin polymer and other materials; Clear characters, patterns, QR codes, etc. shall be marked without damaging the components. Standard machine

1/4

-

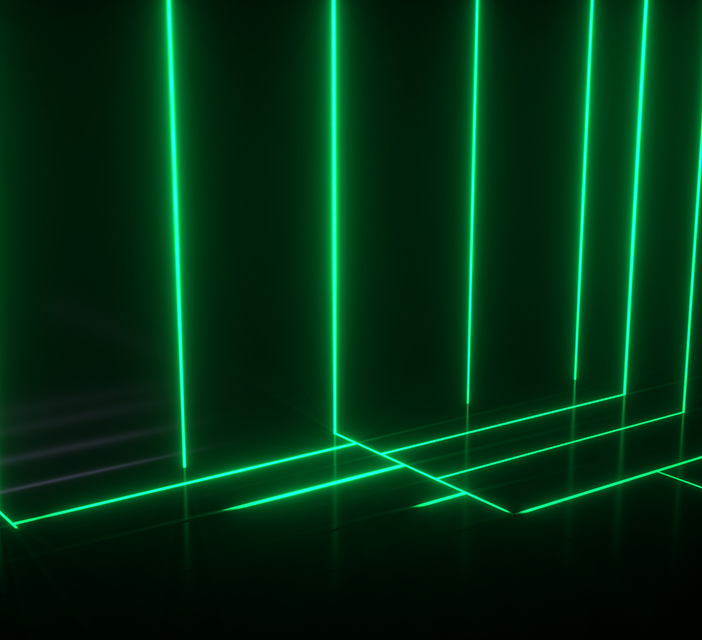

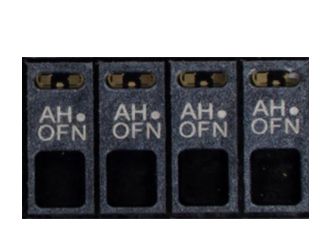

Effect of PCB Resin After Laser Marking

Effect of PCB Resin After Laser Marking -

Effect of PCB Resin After Laser Marking

Effect of PCB Resin After Laser Marking -

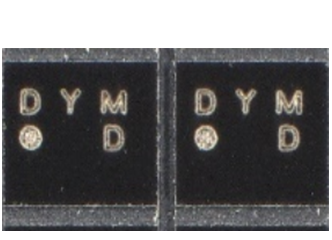

Sampling Effect

Sampling Effect -

Resin Sampling Effect

Resin Sampling Effect

ADVANTAGE

Product Advantages

-

The efficiency of single/double head laser marking system has been greatly improved.

-

The support adopts the automatic loading and unloading method of clip or stack, and the loading, marking and detection can be performed separately.

-

Support MES, remote control and data upload; Unmanned, digital workshop system docking.

-

High-precision CCD visual positioning ensures the accuracy of marking position, and confirms the printing content and quality after marking.

-

Standard SMEMA interface and network communication function can communicate with upstream and downstream devices and servers.

-

Basic Information

- Dimension:L2600mm x W1350mm x H1700mm

- Product dimension:50×50mm-300×150mm

- Thickness:0.5mm-5mm

-

Product Performance

- Laser wave length:532nm/1064nm

- Laser type:green light/infrared

- Laser head:single/double head optional (high efficiency)

- Loading and unloading mode:clip type/stacking type

-

Model classification

- P7

INQUIRY