-

Hymson Laser

-

Products

Coating & Calendering & Slitting Manufacturing

High-Speed Laser Notching Intelligent Manufacturing

High Speed Laser Ablation

High Speed Winding

Intelligent Solutions for Assembly Line

Solutions for the Top-Cover Assembly of the Battery

Auto Battery Baking Solutions

EV Battery Module/Pack

Laser

- Laser Cutting

- Laser Beam Welding

- Laser Surface Treating

- Core Luminous

- Laser Control System

Automation

- Precision Assembly

- Machine Vision

- Roll-to-roll

Intelligent Manufacturing

- PLC Software Framework Platform

- PC Software Framework Platform

- Digital Twin

- Digital simulation

- Virtual commissioning

Basic Technology

- Advanced Testing

- Physical Simulation Computing Platform

Reset

-

View ProductsAuto Assembly Line of Top Cover

View ProductsAuto Assembly Line of Top Cover-

Systemized dust and particle prevention treatment.

-

Equipped with self-inspection and foolproof functions for incoming materials.

-

MES system full closed-loop production processing

-

Less spatter, good weld effect and high stability

-

-

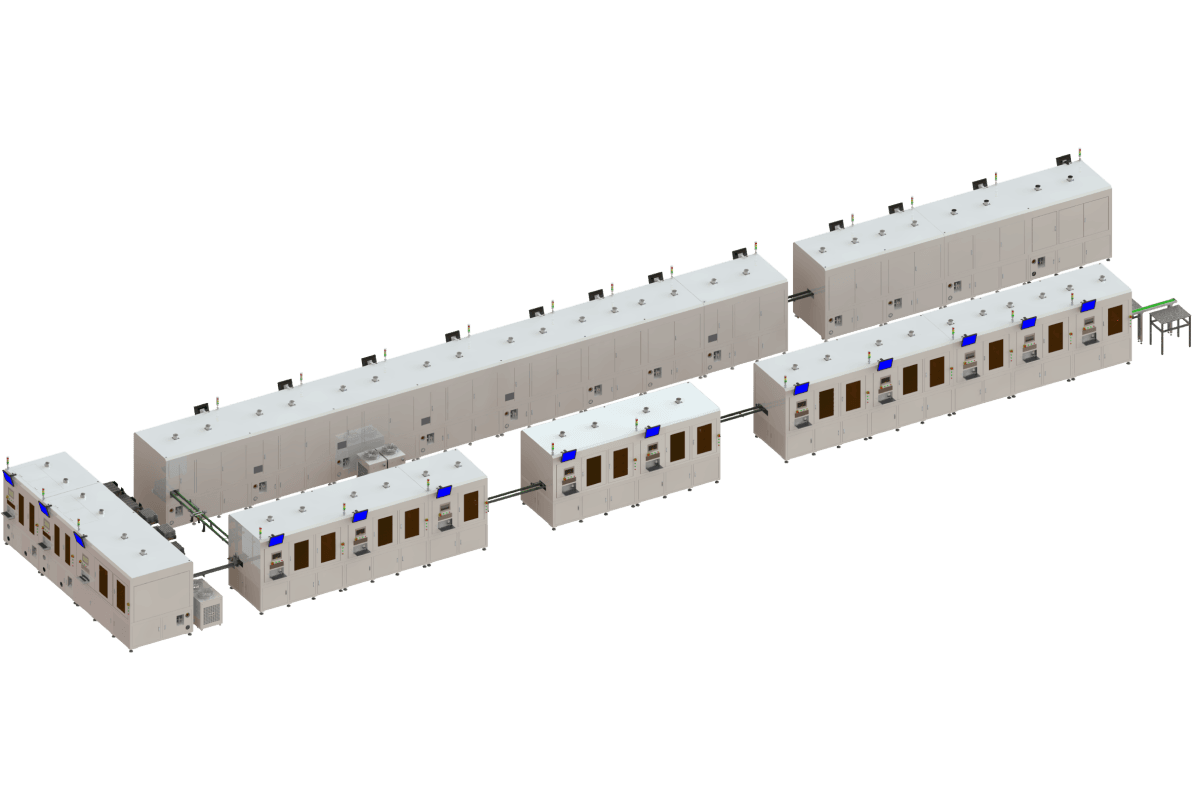

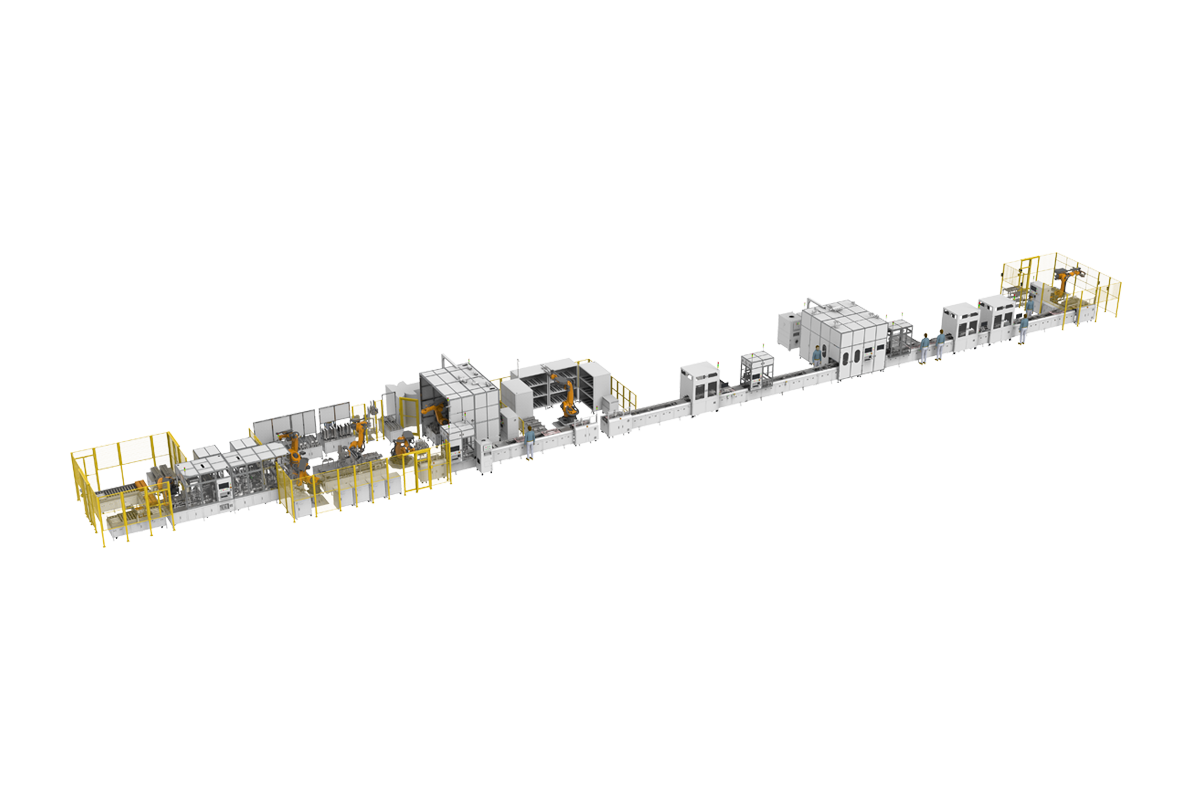

View ProductsFull-Auto Prismatic Cell Assembly Line

View ProductsFull-Auto Prismatic Cell Assembly Line-

Highly automatic, complete the assembly processes without human intervention

-

Modular design, short changeover time, few parts, low costs

-

Automatic process control with traceable information for the whole processes, which can dock all types of MES systems

-

Digital twin 3D visualization technology, equipment state visualization, intelligent information interaction, improve user experience.

-

-

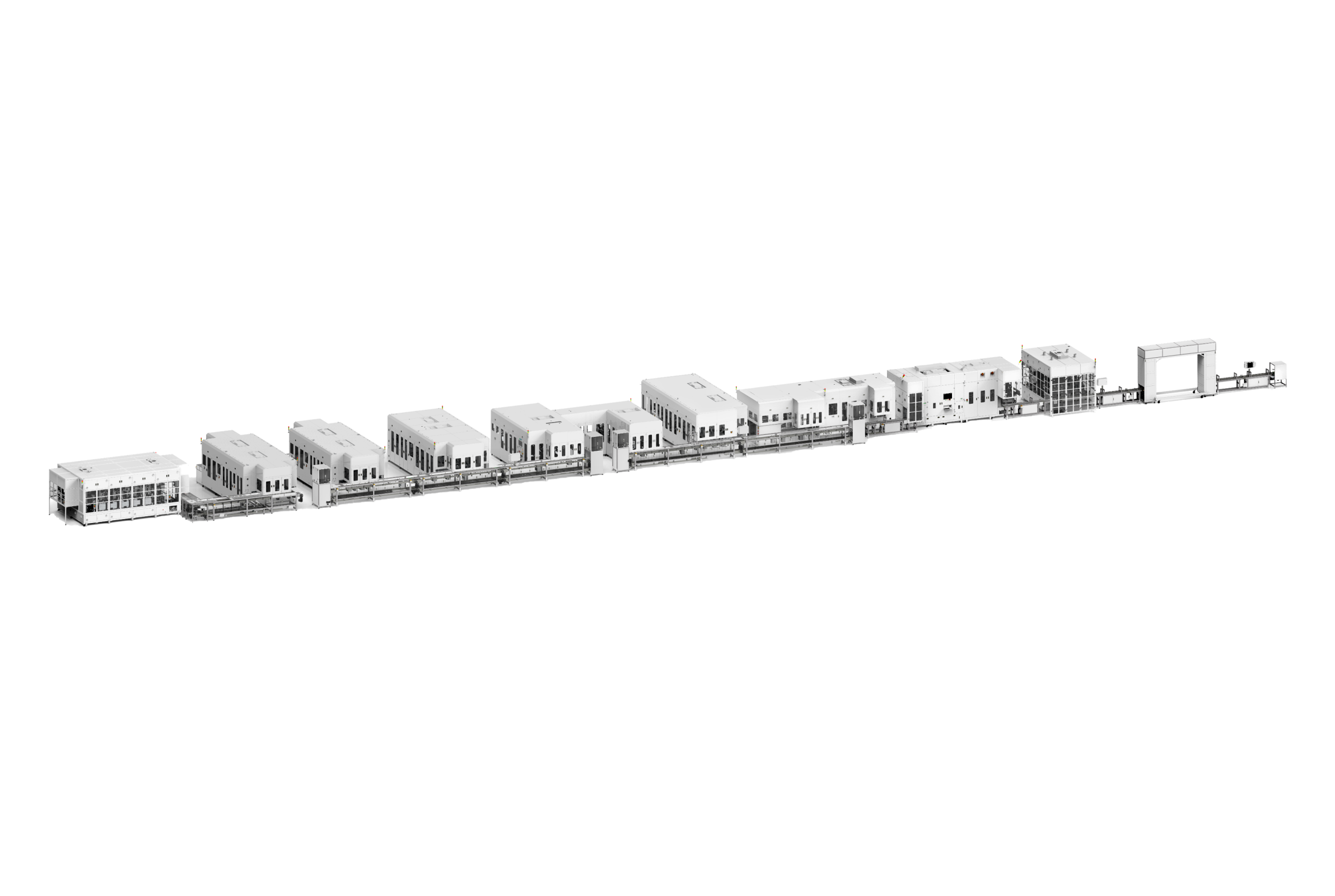

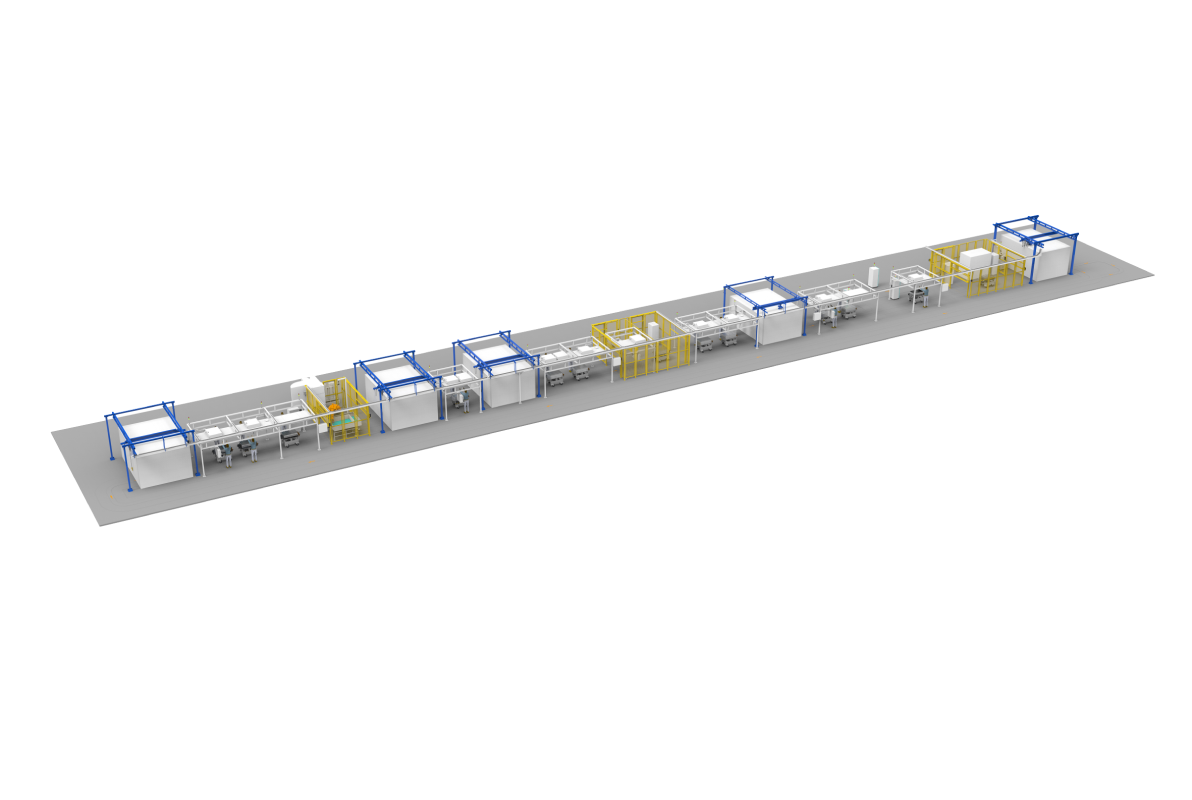

View ProductsModule Assembly Line

View ProductsModule Assembly Line-

Full test of the cell voltage, resistance and thickness to ensure assembly consistency

-

Cell dispensing by two-component nozzle fixed on truss with adjustable glue pressure and mixing ratio and flow monitoring function

-

Unified standards for cell stacking, with high stacking accuracy and one-button switching of stacking modes

-

Visual addressing and off-focus measuring before laser welding to avoid missing welding and incomplete welding, and guarantee welding quality

-

-

View ProductsPACK Assembly Line

View ProductsPACK Assembly Line-

Completing the transmission of packs between stations by latent traction AGV.

-

Each station can be controlled independently.

-

6-axis machine equipped with two-component gluing heads to glue the bottom cover with adjustable glue pressure and mixing ratio and flow monitoring function

-

MES, full closed loop control system

-

- 1