-

Hymson Laser

-

Products

3C Battery

Power/Transformer

VCM

Electronic Atomization

PCB/SMT

Precision Structural Parts

Brittle Material

Dispensing

New Display

Laser

- Laser Cutting

- Laser Beam Welding

- Laser Surface Treating

- Core Luminous

- Laser Control System

Automation

- Precision Assembly

- Machine Vision

- Roll-to-roll

Intelligent Manufacturing

- PLC Software Framework Platform

- PC Software Framework Platform

- Digital Twin

- Digital simulation

- Virtual commissioning

Basic Technology

- Advanced Testing

- Physical Simulation Computing Platform

Reset

-

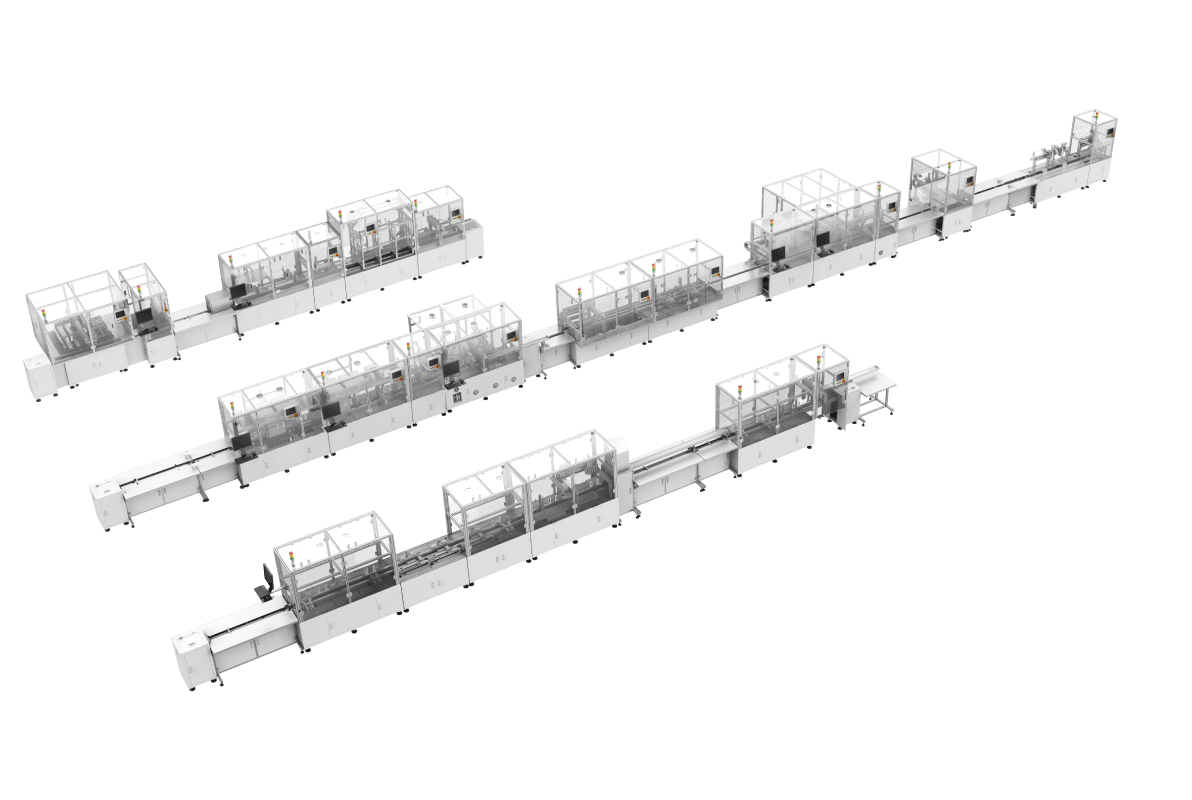

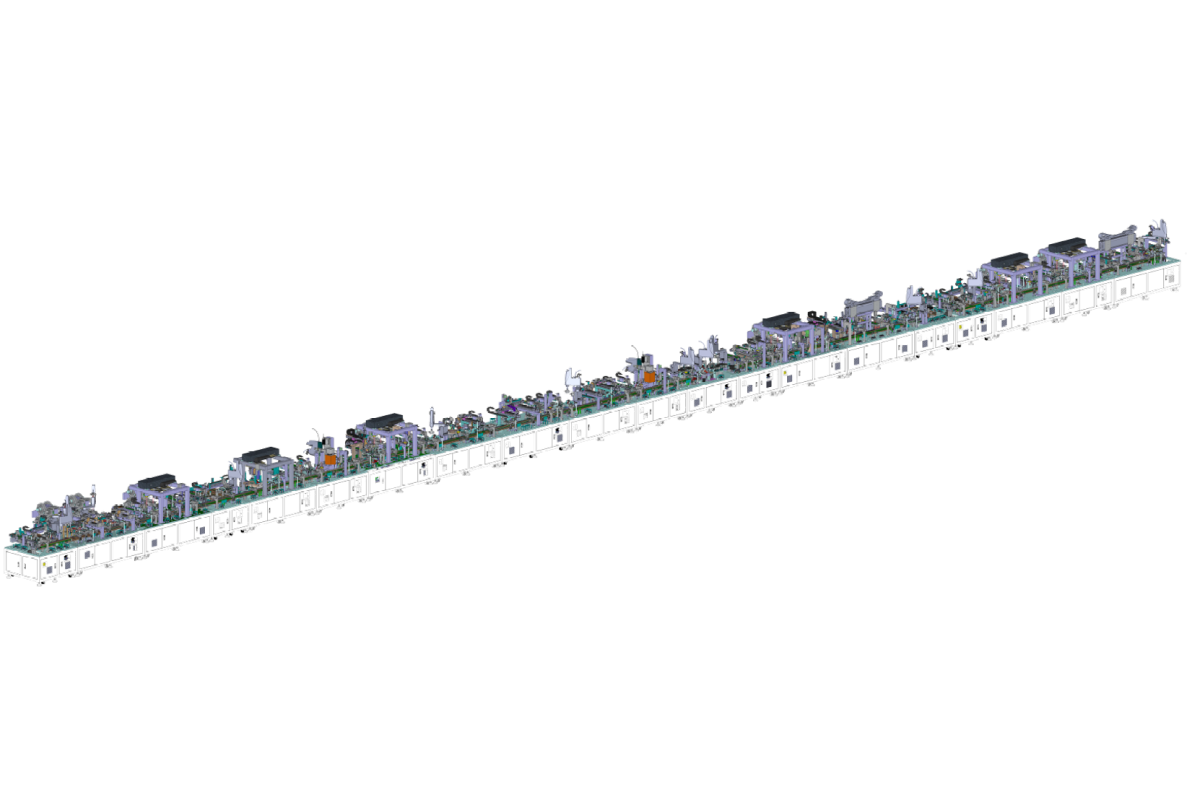

View ProductsTransformer Automatic Assembly Line

View ProductsTransformer Automatic Assembly Line-

More than 50 full-line automated production lines for 3C well-known enterprises are being used for mass production

-

Includes modules such as core automatic loading, AB glue dispensing , core buckling, inductance test, automatic dip-soldering, automatic UV glue dispensing, automatic PIN cutting, automatic laser stripping, taping, hi-pot test, function test,cosmetic inspection, etc.

-

Highly standardized design, low-cost transformation, and rapid mass production of similar products.

-

-

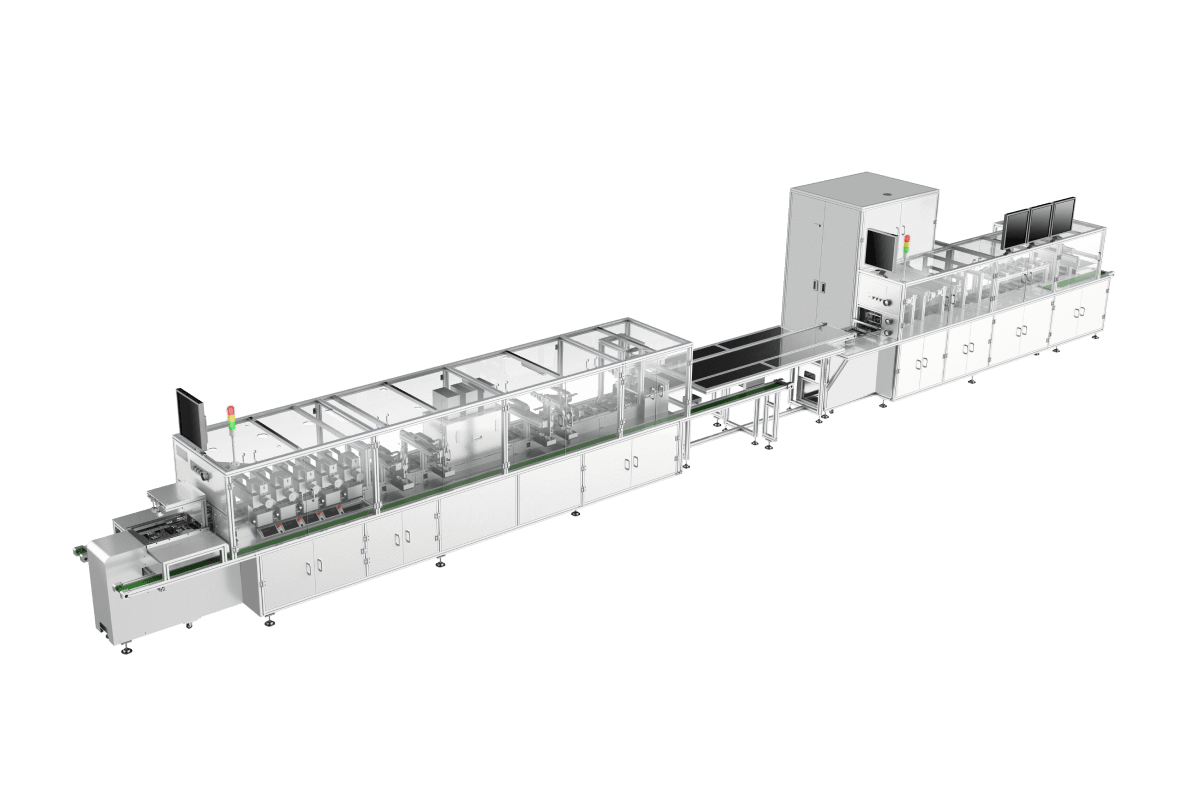

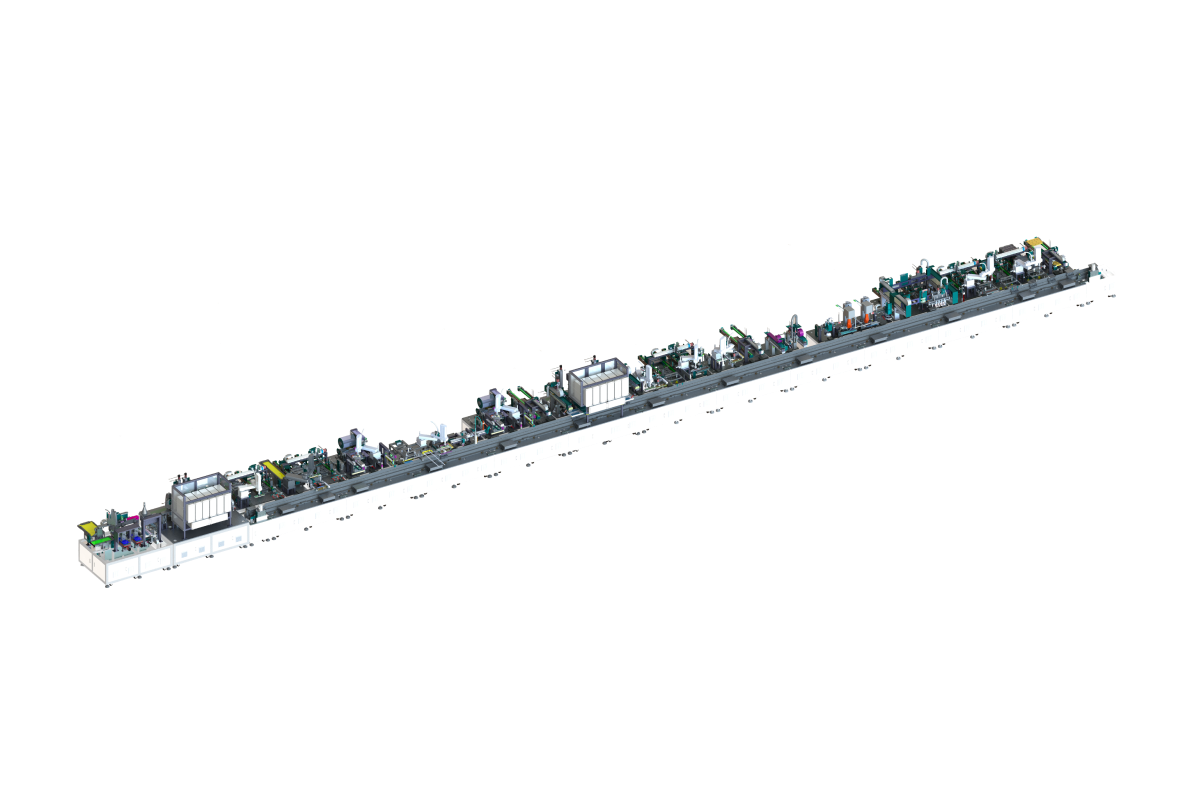

View ProductsPower Automatic Assembly Line

View ProductsPower Automatic Assembly Line-

There are more than 20 automatic assembly lines with automatic soldering, dispensing glue, ultrasonic riveting, detection and laser marking as "body" for mass production.

-

The whole machine adopts modular design, which is convenient for disassembly, customization and transportation of the line.

-

The application of many patents has made the production efficiency and yield of the automatic production line much higher than that of manual operation.

-

-

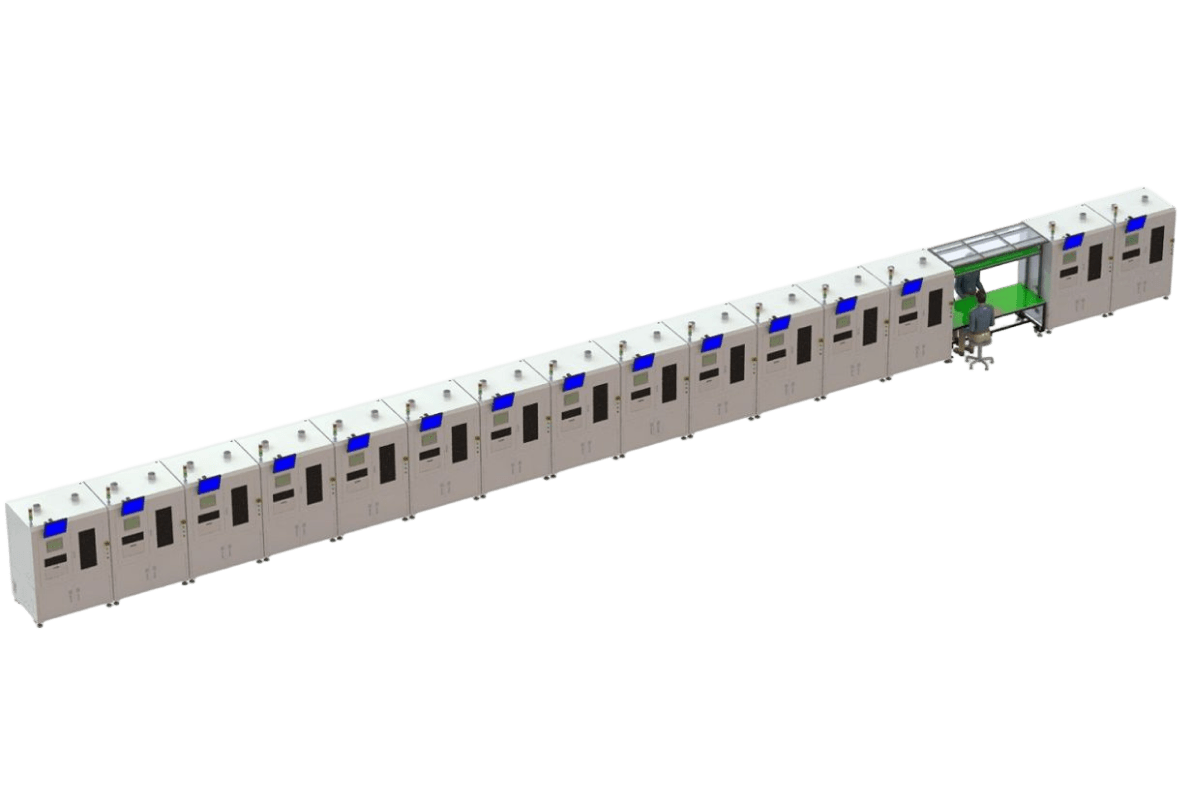

View ProductsLaptop Battery Pack Line

View ProductsLaptop Battery Pack Line-

Adopts industry's most advanced maglev conveying positioning technology to achieve fast and accurate positioning (complete 400mm station spacing in 0.8 seconds, positioning accuracy can reach μ grade).

-

Modular processing module, integrated transmission line. Can conduct quick adjustment and expansion of station.

-

Mainly includes battery assembly, laser welding, dispense heat conduction silica gel, conduction test, code spraying, labeling/packaging Label, labeling Mylar, PPG thickness detection, finished product testing, etc.

-

The MES system controls production in fully closed-loop. The whole line can be equipped with digitalization to observe various indicators of the line in real time.

-

-

View ProductsAuto Soft Pack Battery Pack Line

View ProductsAuto Soft Pack Battery Pack Line-

Mainly includes pad printing, inkjet printing, pole ear cutting, pole ear size detection, grooving glue, PCM assembly/welding, pole ear bending, pole ear adhesive, glue wrapping, Pogo pin test, appearance inspection

-

The equipment adopts single station single rack mode. Has high agility

-

The MES system controls production in fully closed-loop. The whole line can be equipped with digitalization to observe various indicators of the line in real time.

-

-

View ProductsAuto Assembly Line for Steel Shell Button Battery

View ProductsAuto Assembly Line for Steel Shell Button Battery-

Most comprehensive experience in button battery pack technology in the industry. The equipment is compatible with various types of nickel sheet mounting and welding.

-

Mainly include Busbar mounting, bending and welding, adhesive tape mounting, soft plate assembly and bending, laser welding, laser etching, Pogo pin, waterproof film removal, testing, liquid leakage and appearance inspection.

-

The whole line adopts high-speed transmission line design, UPH > 1200. Seperated operation can be conducted by single machine and single process

-

The MES system controls production in fully closed-loop. The whole line can be equipped with digitalization to observe various indicators of the line in real time.

-