-

Hymson Laser

-

Products

OVERVIEW

Product Description

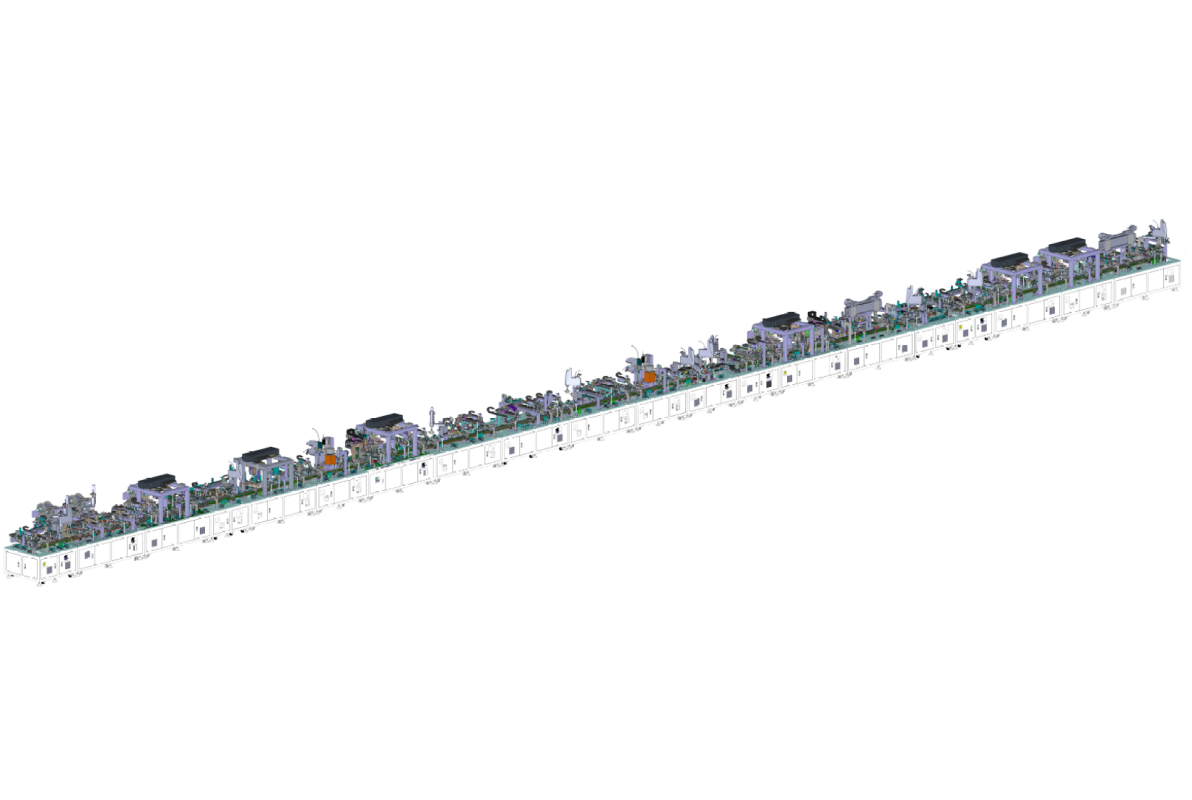

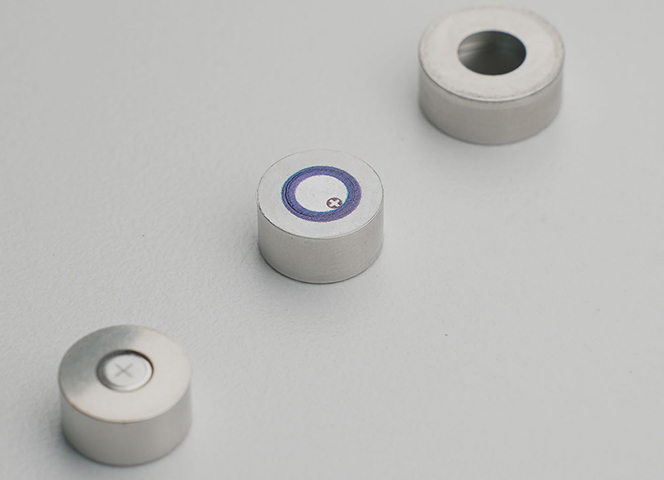

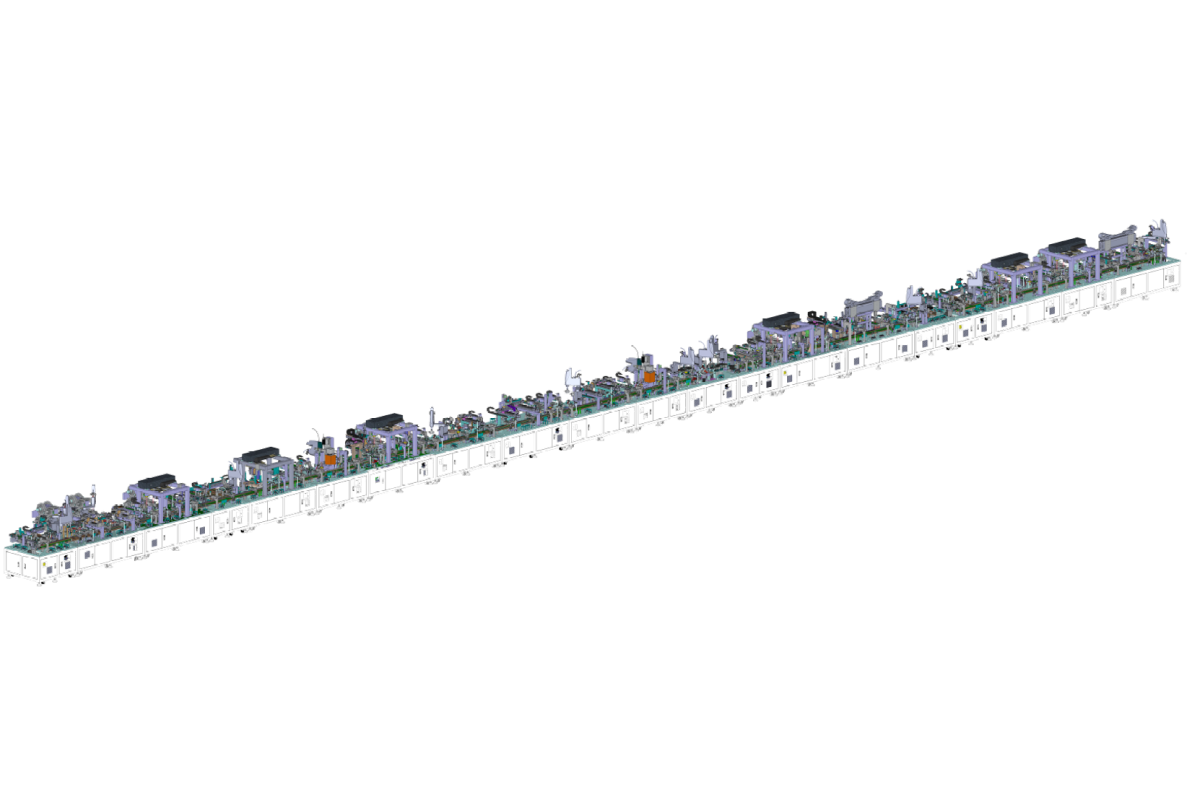

Auto Assembly Line for Steel Shell Button Battery

Hymson has the most comprehensive and top experience in steel shell button battery pack process equipment, and can flexibly configure the following functional modules according to requirements.Busbar/connection piece mounting, bending and welding, adhesive tape mounting, soft plate assembly and bending, laser welding, laser etching, Pogo pin, waterproof film removal, testing, liquid leakage and appearance inspection.

ADVANTAGE

Product Advantages

-

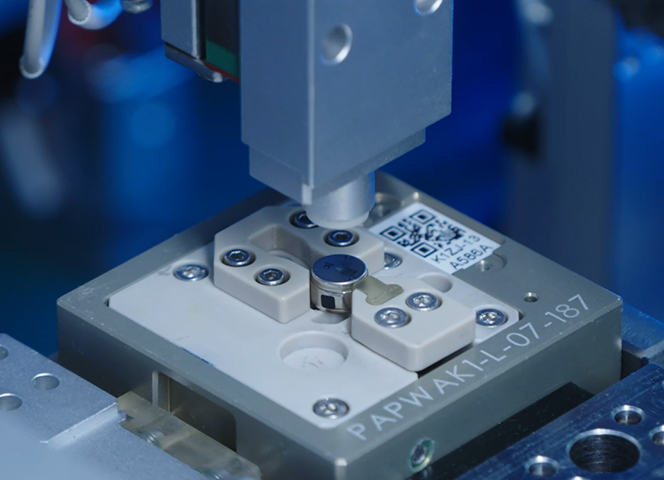

Most comprehensive experience in button battery pack technology in the industry. The equipment is compatible with various types of nickel sheet mounting and welding.

-

Mainly include Busbar mounting, bending and welding, adhesive tape mounting, soft plate assembly and bending, laser welding, laser etching, Pogo pin, waterproof film removal, testing, liquid leakage and appearance inspection.

-

The whole line adopts high-speed transmission line design, UPH > 1200. Seperated operation can be conducted by single machine and single process

-

The MES system controls production in fully closed-loop. The whole line can be equipped with digitalization to observe various indicators of the line in real time.

-

Basic Information

- Size:L42m×W1m×H1.9m

- UPH:1200

-

Product Performance

- Yield:99.7-99.9% (single station)

- Stability:Down time<2% (whole line)

INQUIRY