-

Hymson Laser

-

Products

Body Sheet Metal Processing

Automobile Electronic Module

Automotive Display Module Solution

Laser Plastic Welding

Laser

- Laser Cutting

- Laser Welding

- Laser Surface Treating

- Core Luminous

- Laser Control System

- Laser Plastic Welding

Automation

- Precision Assembly

- Machine Vision

- Roll-to-roll

Intelligent Manufacturing

- PLC Software Framework Platform

- PC Software Framework Platform

- Digital Twin

- Digital simulation

- Virtual commissioning

Basic Technology

- Advanced Testing

- Physical Simulation Computing Platform

Reset

-

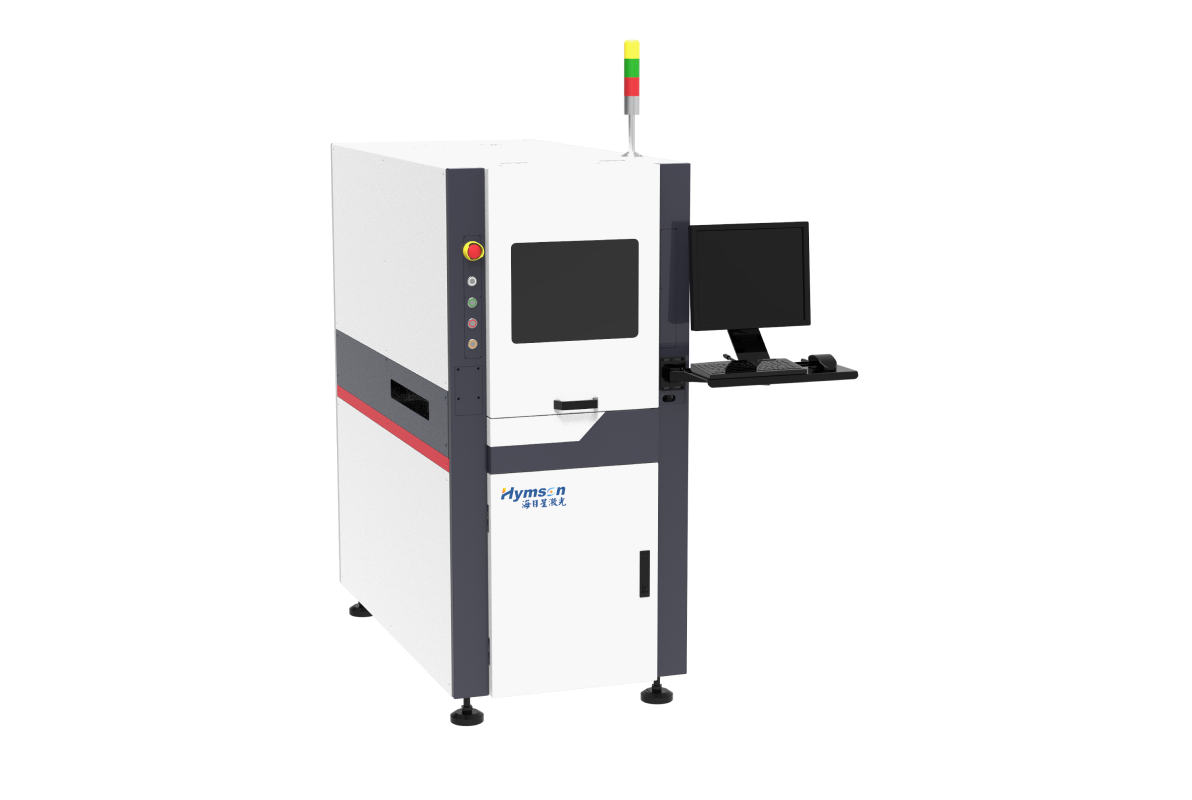

View ProductsAuto PCB Laser Marking Machine

View ProductsAuto PCB Laser Marking Machine-

Support MES, unmanned and digital workshop system docking.

-

Can be configured with high-performance CO2, optical fiber, green light and UV laser, and with adjustable power.

-

Easy to operate and can etch various patterns, characters, 2D codes, 1D codes and other contents.

-

Highly intelligent, high precision, strong system stability, true coaxial technology. Can conduct marking and reading immediately, and with faster efficiency.

-

-

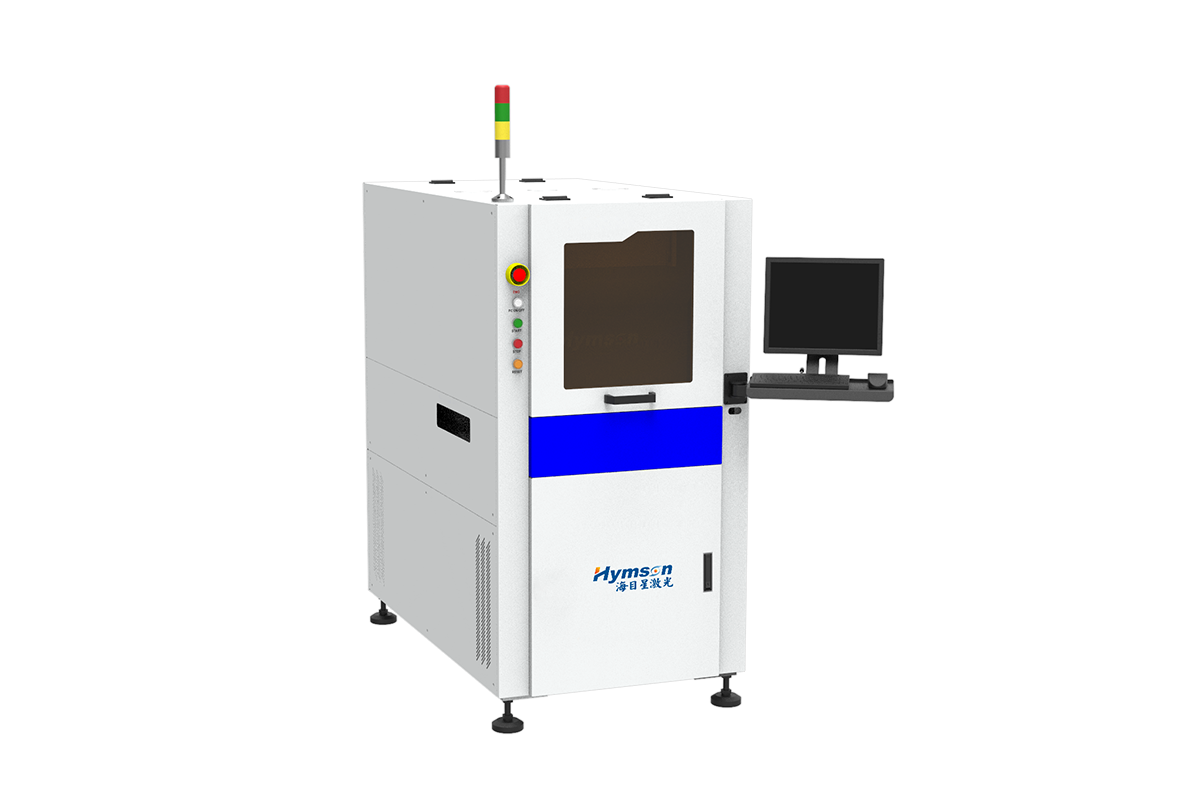

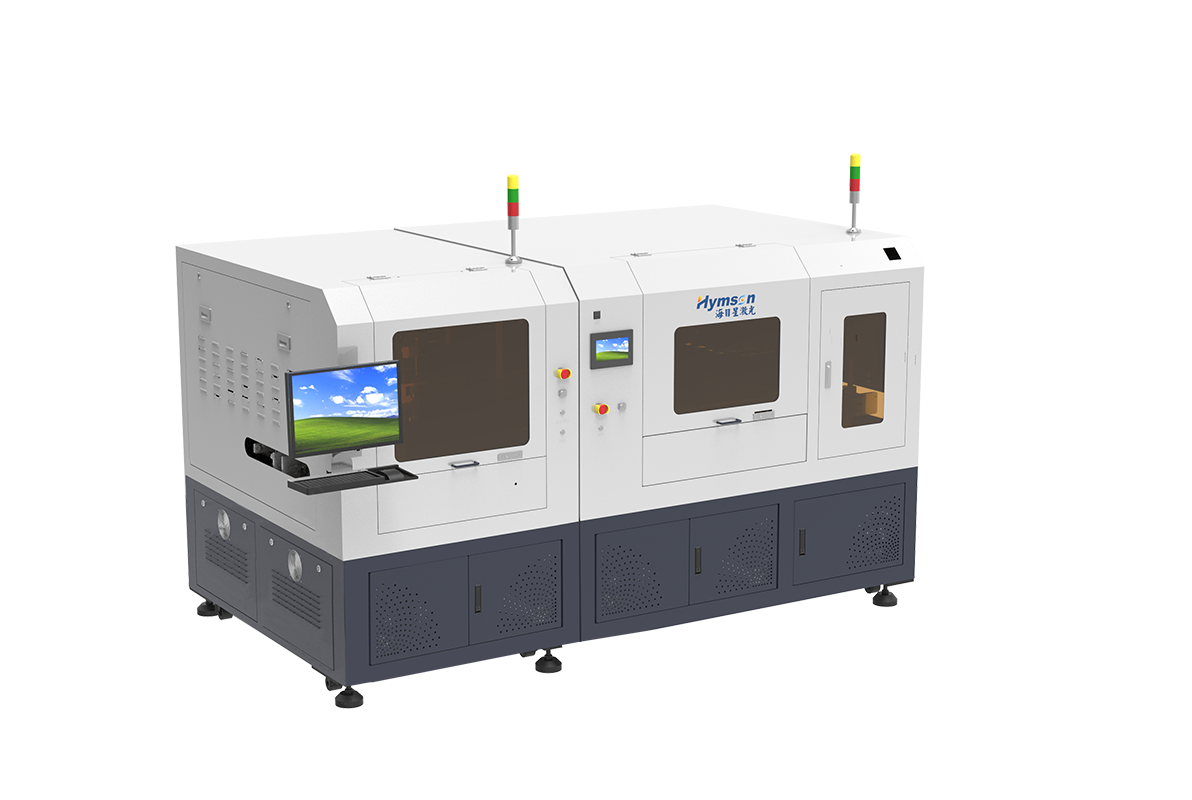

View ProductsDouble Station Laser Cutting Machine

View ProductsDouble Station Laser Cutting Machine-

Stress-free cutting avoids product damage caused by stress of material.

-

Dust free and environmental friendly.

-

The section of cutting surface is smooth and neat without burr and carbonization.

-

Applicable for the cutting of soft and hard bonding plates, with high precision for plate splitting.

-

-

View ProductsPCB/FPC Online Laser Cutting Machine

View ProductsPCB/FPC Online Laser Cutting Machine-

No dust. Minor pollution to the environment

-

The cut surface section is smooth without burr and carbonization.

-

Non-stress cutting. Can avoid product damage caused by material stress.

-

Applicable to cutting soft and hard combination plates. The accuracy of plate splitting is high.

-

-

View ProductsAuto Laser Cutting Machine

View ProductsAuto Laser Cutting Machine-

No dust. Minor pollution to the environment

-

The cut surface section is smooth without burr and carbonization.

-

Non-stress cutting. Can avoid product damage caused by material stress.

-

Applicable to cutting soft and hard combination plates. The accuracy of plate splitting is high.

-

-

View ProductsNOVOLAS Basic M

View ProductsNOVOLAS Basic M-

Modular building block system.

-

Variable integration depth.

-

Configuration determines process responsibility.

-

Several welding concepts possible.

-

-

View ProductsNOVOLAS Basic S

View ProductsNOVOLAS Basic S-

Flexible, modular laser system for integration.

-

Flexible, inexpensive, suited for a variety of applications.

-

High throughput.

-

Modular construction with diverse optional components.

-