-

Hymson Laser

-

Products

BAPV

BIPV

Elevator

Modern Business Display Technology

Security monitoring

UPS

Laser

- Laser Cutting

- Laser Beam Welding

- Laser Surface Treating

- Core Luminous

- Laser Control System

Automation

- Precision Assembly

- Machine Vision

- Roll-to-roll

Intelligent Manufacturing

- PLC Software Framework Platform

- PC Software Framework Platform

- Digital Twin

- Digital simulation

- Virtual commissioning

Basic Technology

- Advanced Testing

- Physical Simulation Computing Platform

Reset

-

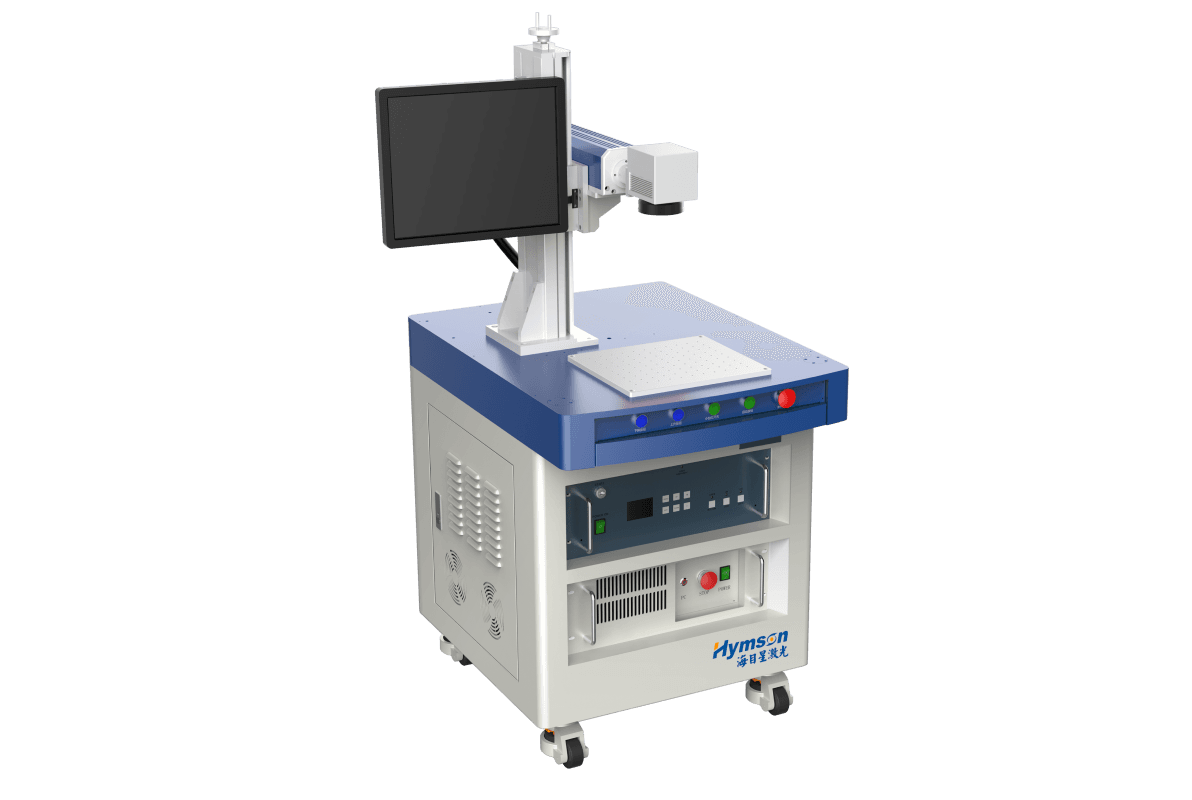

View Products"Falcon" Series Laser Marking Machine Module

View Products"Falcon" Series Laser Marking Machine Module-

Stable performance, can work for a long time.

-

Support PLT, PCX, DXF, BMP and other files, directly use the SHX, TIF library.

-

Support industry 4.0 and intelligent manufacturing, and create a new production mode.

-

Small size, easy to integrate.

-

-

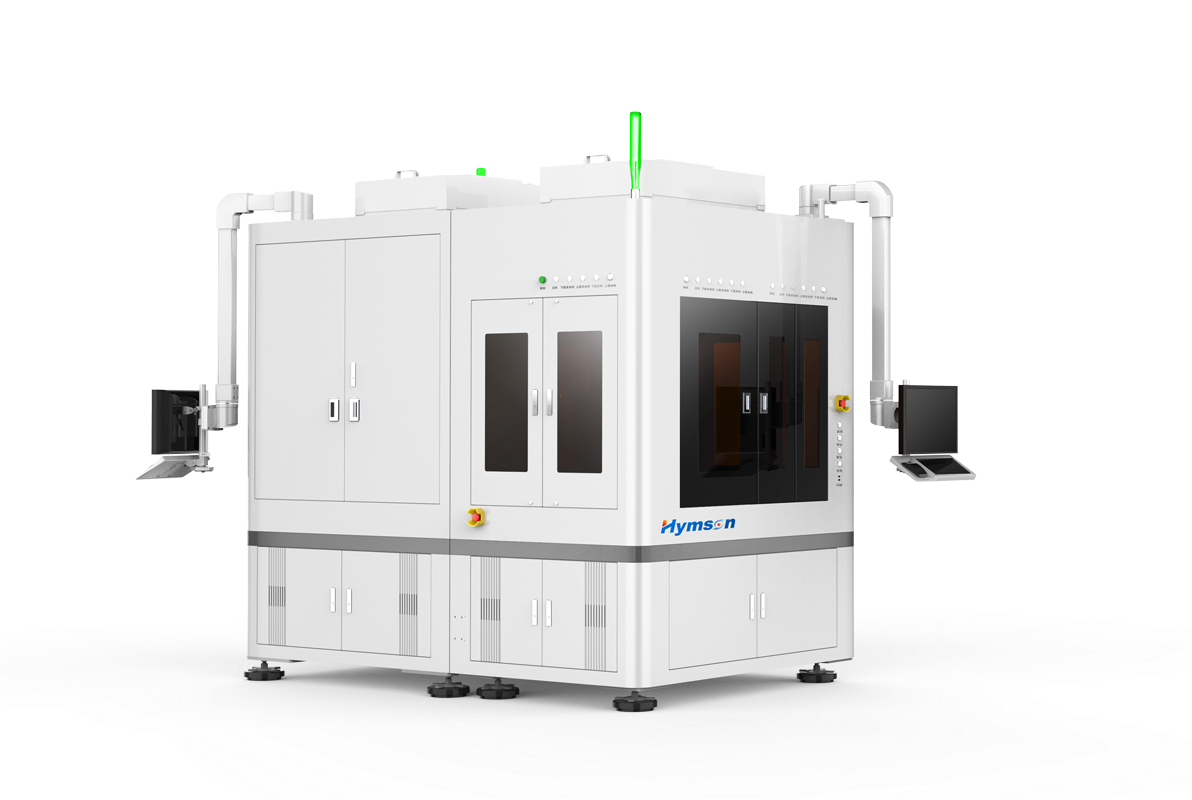

View ProductsMicro LED Laser Mass Transfer Machine

View ProductsMicro LED Laser Mass Transfer Machine-

This machine has automatic splicing and re-pitch function, which can transfer one or three color Micro led chip arrays of any size and pitch to target substrate.

-

Simultaneously compatible with mass transfer and repair processes, the yield of mass transfer is ≥99.99%, and the yield after repair is ≥99.99%.

-

The maximum size of the laser transfer product can reach 12.7inch, and the laser transfer accuracy is ≤±1.5μm, the laser transfer angle is ≤±1°.

-

Automatic transfer of RGB chips.

-

-

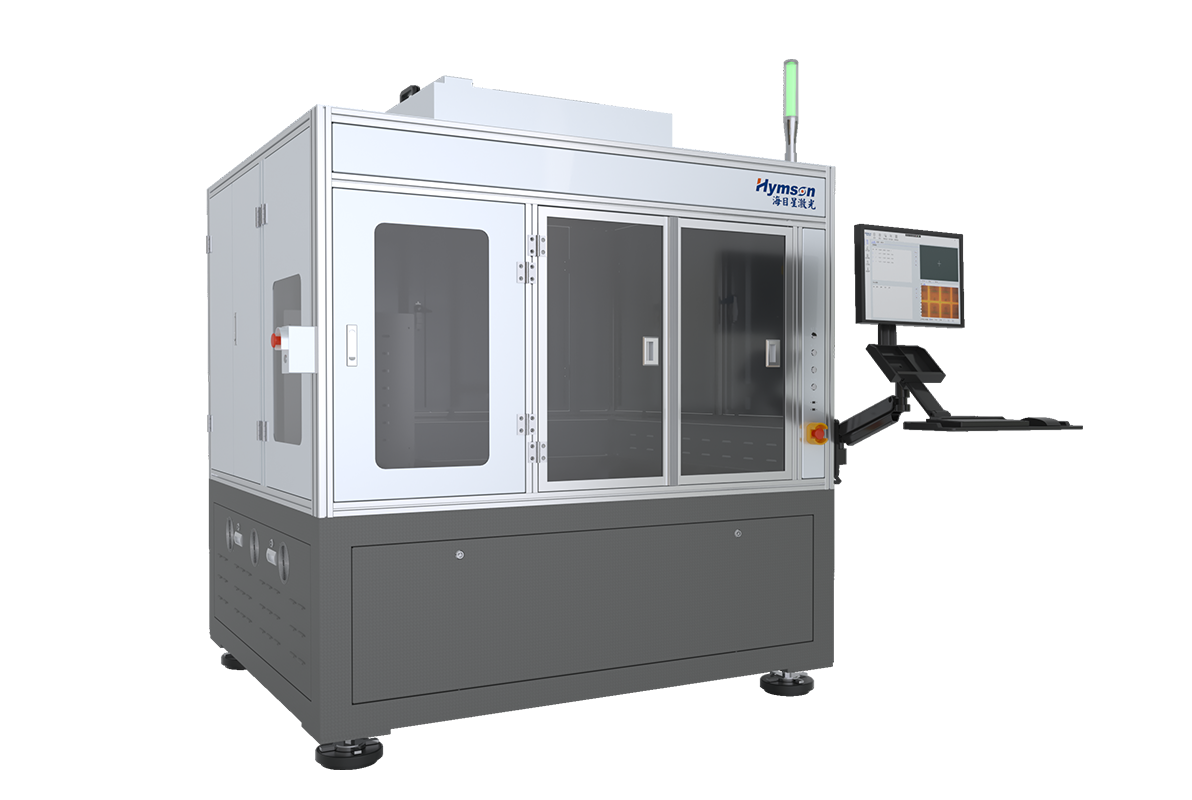

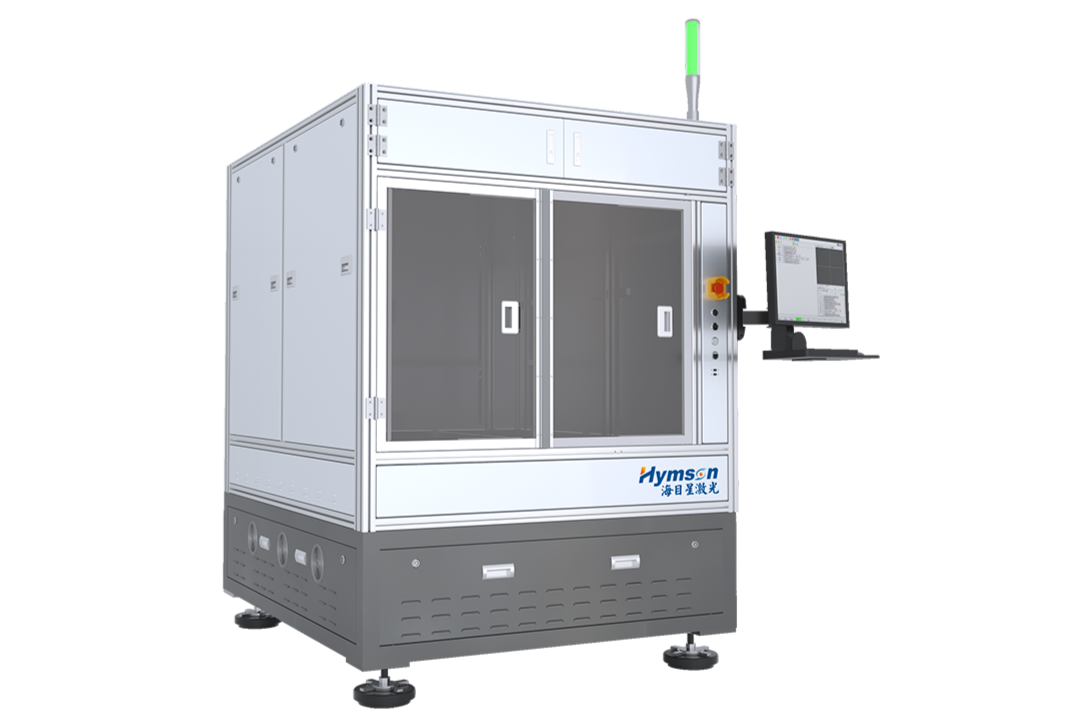

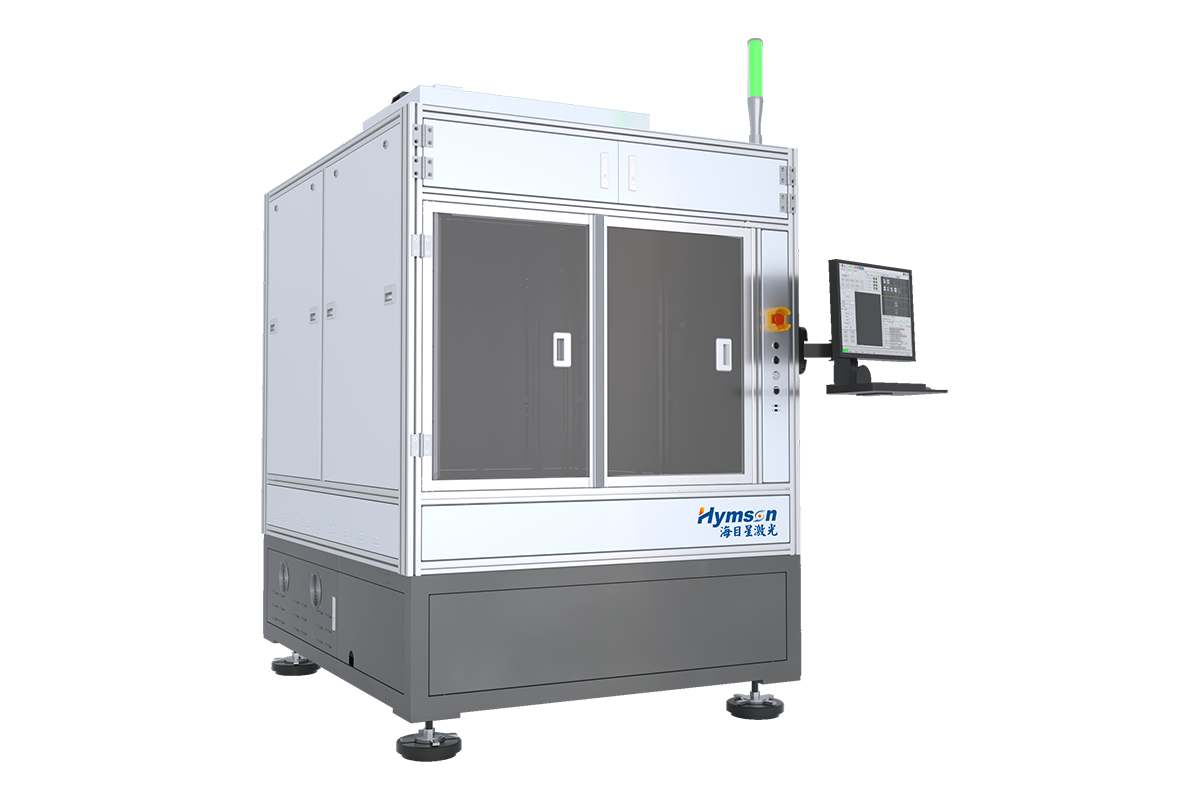

View ProductsHigh Precision Laser Automatic Wafer Cutting Equipment

View ProductsHigh Precision Laser Automatic Wafer Cutting Equipment-

Realize high-precision cutting of wafer brittle materials without chipping and cracks

-

Hymson company self-developed cutting head to achieve cutting of glass of different thicknesses

-

Compatible with different types and sizes of products

-

-

View ProductsLaser Welding Repair Equipment

View ProductsLaser Welding Repair Equipment-

Coaxial visual positioning system, high-precision positioning chip position, real-time monitoring of product status and effect in the welding repair process

-

Real-time monitoring of welding temperature, closed-loop temperature control, to ensure welding quality

-

Optional AOI system to instantly confirm welding success rate

-

-

View ProductsFully Automatic Chip Removal Equipment

View ProductsFully Automatic Chip Removal Equipment-

Coaxial visual positioning system, high-precision positioning chip position

-

Accurate detection of welding pad height trims residual tin paste on the welding pad without damaging the welding pad

-

Flexibly select laser or mechanically remove chips

-

-

View ProductsMini LED/Micro LED Fully Automatic Laser Repair、 Removal and Trimming Equipment

View ProductsMini LED/Micro LED Fully Automatic Laser Repair、 Removal and Trimming Equipment-

Used for the removal of rubber material after sealing of Mini LED module and the trimming of welding pads after decrystallization in each process section, which is compatible with products of different thicknesses and sizes

-

Matching micron-level light spot removes the chip encapsulant of micro LED as small as 5μm without damaging adjacent chips and welding pads

-